a washing machine

A washing machine and washing tub technology, applied in the field of washing machines, can solve the problems of wear and tear of drain pipes, easy collision with the inner wall of the box, and short-circuit failure of the washing machine, and achieve the effects of prolonging the service life, avoiding the short-circuit problem and improving the utilization rate.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0023] The specific embodiments of the present invention will be described in further detail below in conjunction with the accompanying drawings.

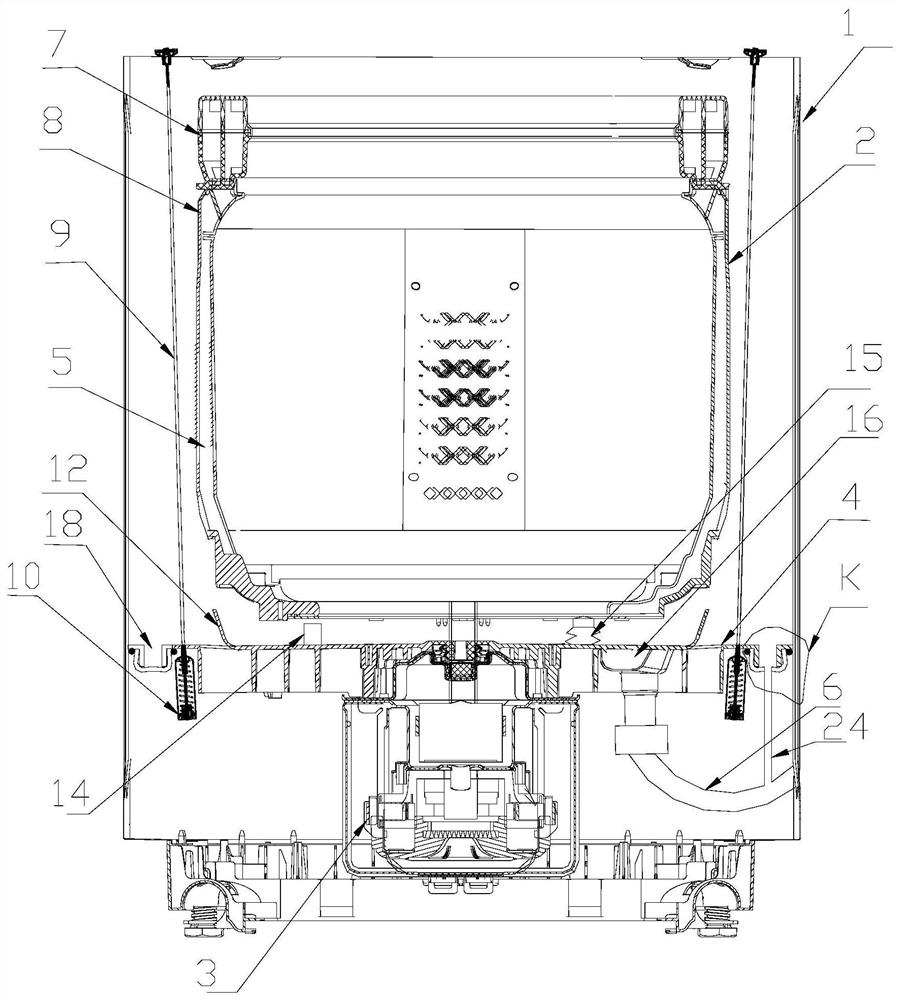

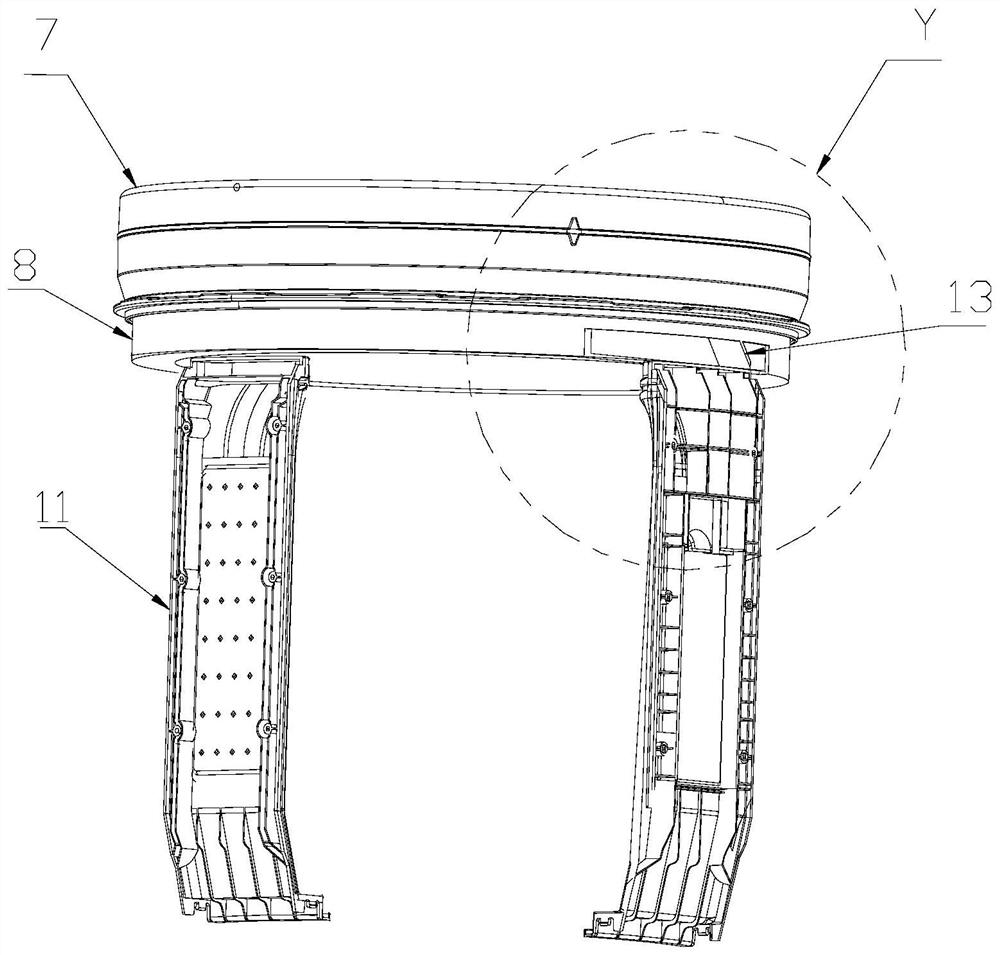

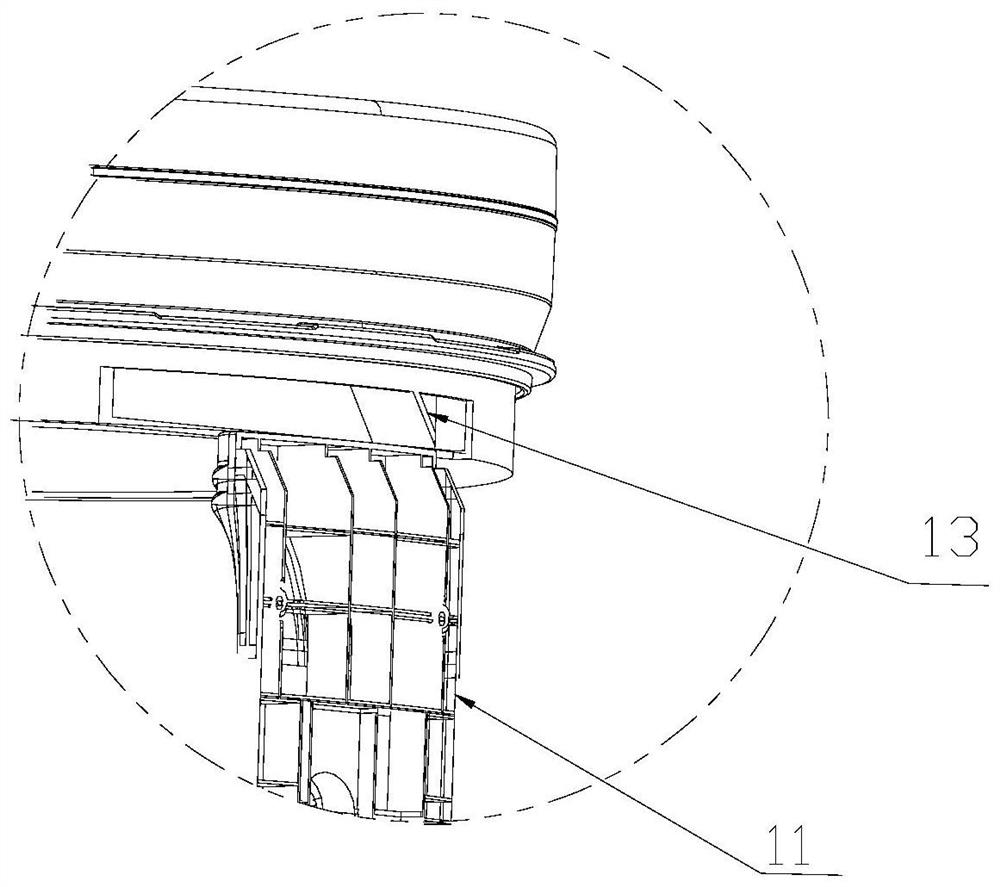

[0024] Such as figure 1 As shown, a washing machine includes a cabinet 1, a washing tub 2 for accommodating laundry, a power device 3 for driving the washing tub 2 to rotate, a mounting plate 4 installed at the lower part of the washing tub 2, and a connecting mounting plate 4 With the vibration damping component of the box body 1, the mounting plate 4 is suspended in the box body 1 through the damping component. The washing tub 2 is rotatably arranged in the box body 1. The washing tub 2 is seated on the mounting plate 4 and can be rotated relative to the mounting plate 4. The washing tub 2 is used as a tub for containing washing water, and the mounting plate 4 is used for The washing tub 2 is supported, and the mounting plate 4 is movably connected to the box body 1 through a vibration damping component. During washing or dehydratio...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com