Split type drive short roller device for drawing glass

A split-type, short-roller technology, applied in the field of driving short-roller devices, can solve the problems of high manufacturing difficulty, inability to realize flexible process adjustment, and high cost, and achieve the effect of good compatibility

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0044] The present invention will be further described in detail below in conjunction with specific embodiments, which are explanations of the present invention rather than limitations.

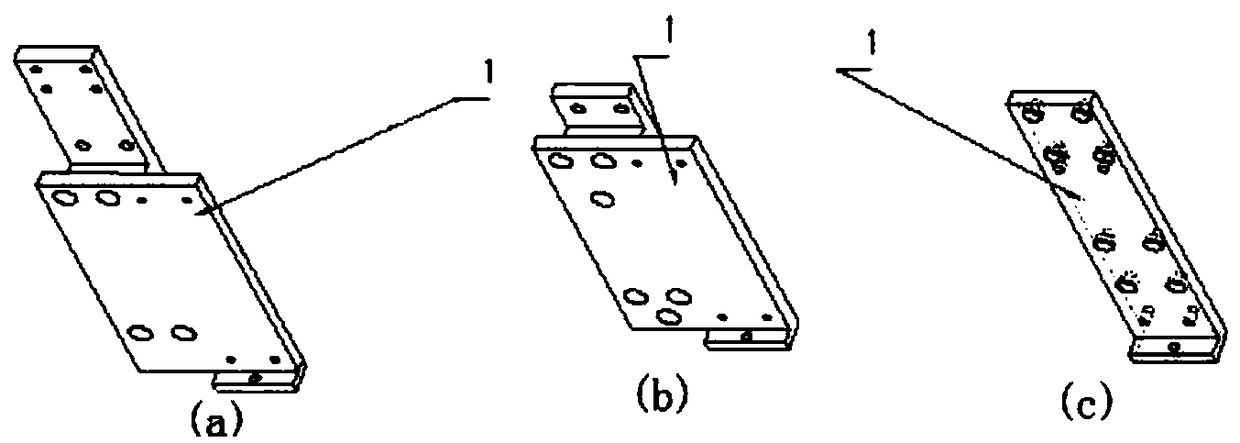

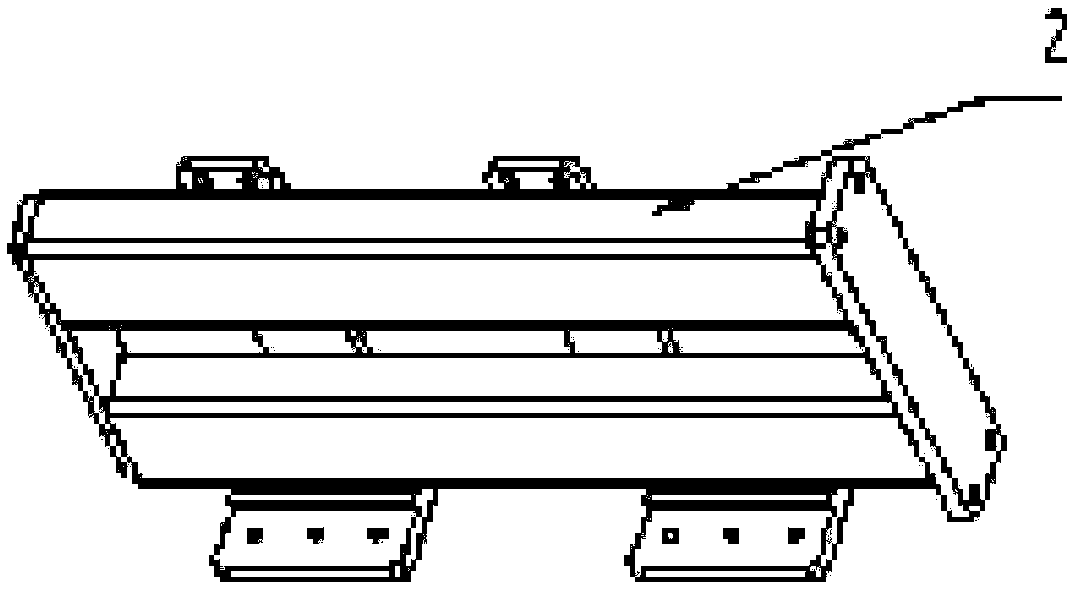

[0045] The driving short roller device of the split-type drawing glass of the present invention includes a transition plate 1, and the transition plate 1 is designed according to the actual annealing furnace, for example, it can be as follows figure 1 (a), figure 1 (b) and figure 1 (c) Structure shown. It also includes two brackets 2 on the left and right sides, and the brackets 2 are installed on the transition board 1, such as figure 2 As shown, the device can be compatible installed on different TFT substrate glass production line forming equipment through the transition plate 1 .

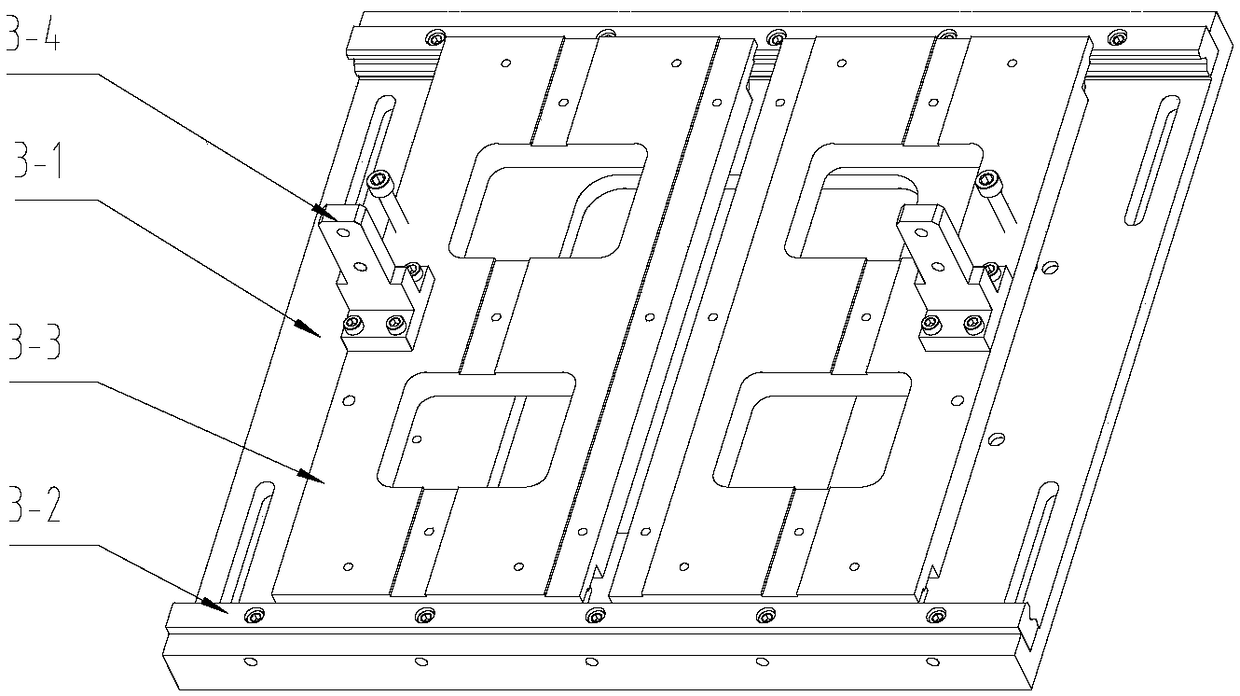

[0046] A horizontal slide mechanism 3 is installed between the two supports 2; the structure of the horizontal slide mechanism 3 is as follows: image 3As shown, including the bottom plate 3-1, the bottom ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com