Treatment method and treatment device for isooctyl thioglycolate production wastewater

The technology of isooctyl thioglycolate and isooctyl acetate is applied in the field of treatment method and treatment device of isooctyl thioglycolate production wastewater, which can solve the problems of inorganic salt pollution, difficulty in meeting discharge requirements, and inability to oxidatively degrade organic matter. , to achieve the effect of recycling, low processing cost and prolonging service life

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

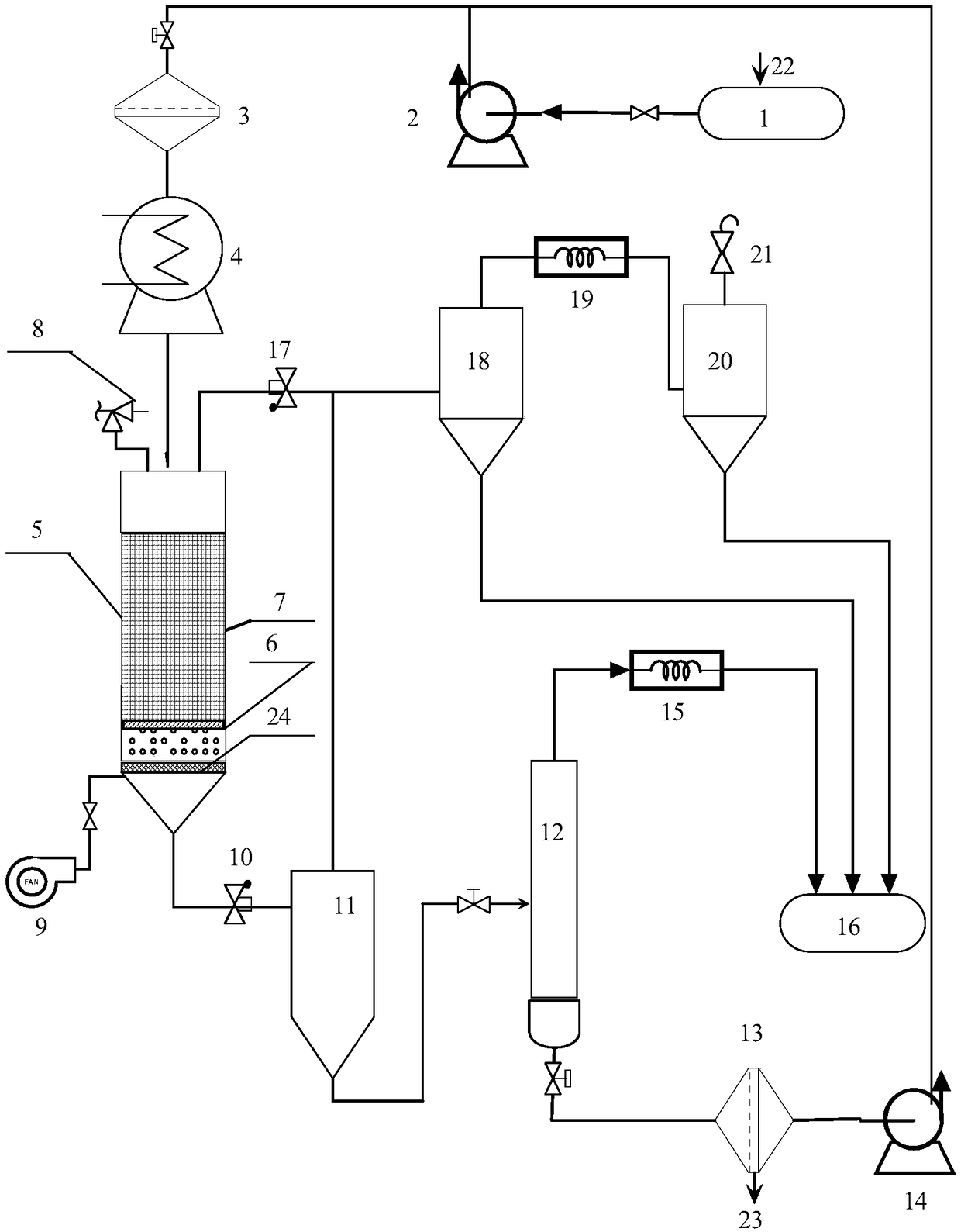

Method used

Image

Examples

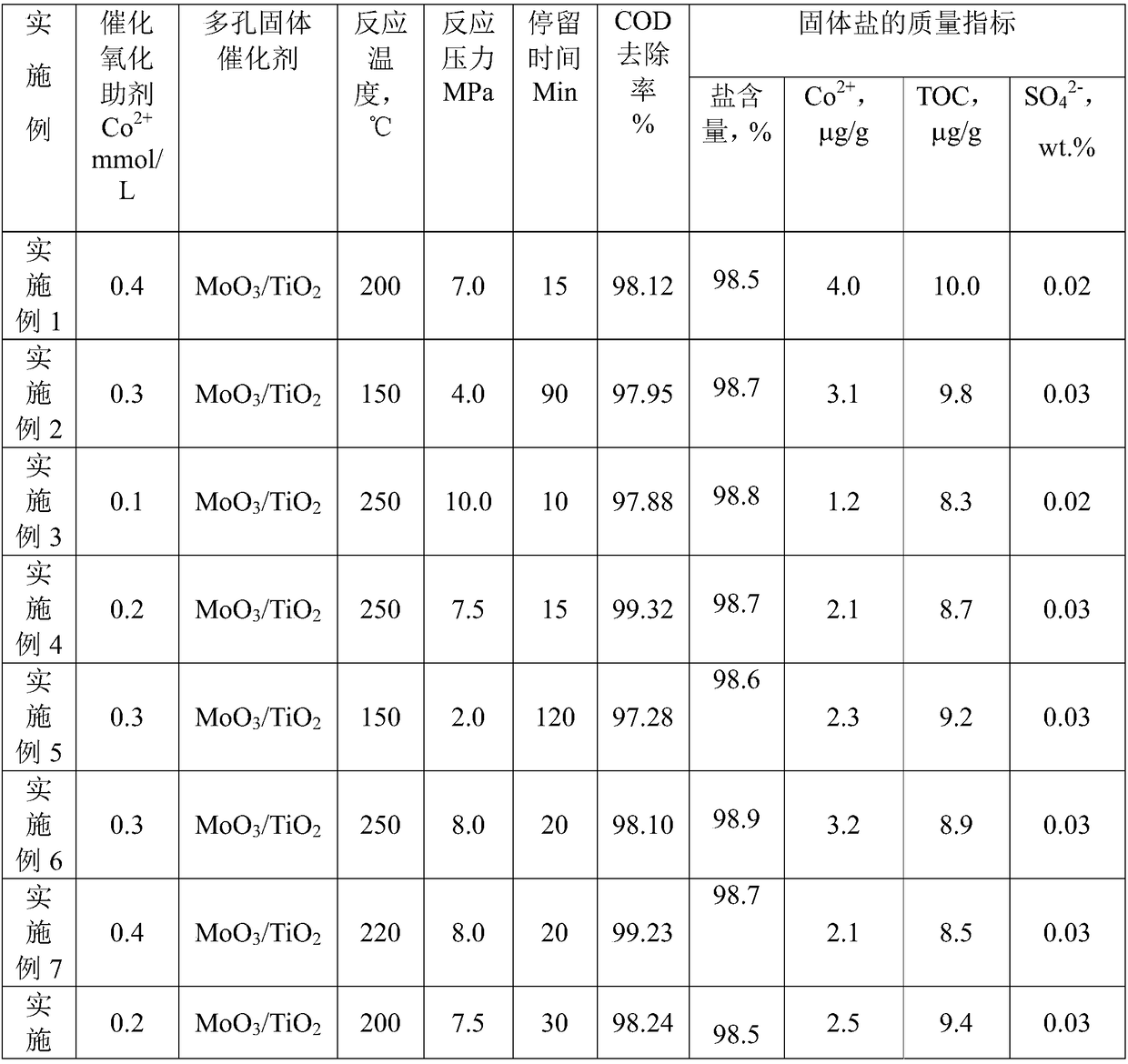

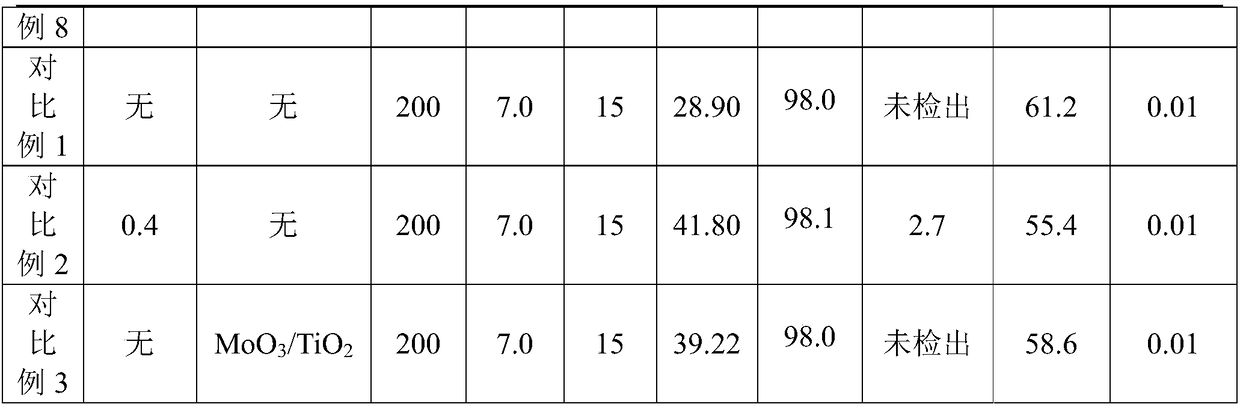

Embodiment 1

[0032] (1) Get isooctyl thioglycolate production waste water (NaCl content 17.0wt.%, COD: 15000mg / L, pH value is 0.5) join in the waste water storage tank, add catalytic oxidation auxiliary agent anhydrous cobalt chloride and stir evenly, Co in organic wastewater 2+ The molar concentration is 0.4mmol / L;

[0033] (2) Preheat to 200°C, enter the porous solid catalyst MoO 3 / TiO 2 React with oxygen in the bubbling reactor; control the reaction temperature to 200°C, the reaction pressure to 7.0MPa, the residence time to 15min, and the flow rate of waste water to 66.7ml / min;

[0034] (3) Sampling and analysis at the outlet of the bubbling reactor, then enter the flashing device, cool down, and centrifuge the solid salt NaCl through the desalting filter, return the concentrated solution after centrifugation to the filtering device, then enter the preheating device, and apply it to In the process, the recycling of catalytic oxidation aids is realized.

[0035] After testing, the ...

Embodiment 2

[0037] (1) Take isooctyl thioglycolate production wastewater (NaCl content 17.0wt.%, COD: 15000mg / L, pH value is 5.0) and join in the wastewater storage tank, add catalytic oxidation auxiliary agent anhydrous cobalt chloride and stir evenly, Co in organic wastewater 2+ The molar concentration is 0.3mmol / L;

[0038] (2) Preheat to 150°C, enter the porous solid catalyst MoO 3 / TiO 2 React with oxygen in the bubbling reactor; control the reaction temperature to 150°C, the reaction pressure to 4.0MPa, the residence time to 90min, and the flow rate of waste water to 11.1ml / min;

[0039] (3) Sampling and analysis at the outlet of the bubbling reactor, then enter the flashing device, cool down, and centrifuge the solid salt NaCl through the desalting filter, return the concentrated solution after centrifugation to the filtering device, then enter the preheating device, and apply it to In the process, the recycling of catalytic oxidation aids is realized.

[0040] After testing, t...

Embodiment 3

[0042] (1) Take isooctyl thioglycolate production wastewater (NaCl content 20.0wt.%, COD: 20000mg / L, pH value is 3.0) and join in the wastewater storage tank, add catalytic oxidation auxiliary agent anhydrous cobalt chloride and stir evenly, Co in organic wastewater 2+ The molar concentration is 0.1mmol / L;

[0043] (2) Preheat to 250°C, enter the porous solid catalyst MoO 3 / TiO 2 React with oxygen in the bubbling reactor; control the reaction temperature to 250°C, the reaction pressure to 10.0MPa, the residence time to 10min, and the flow rate of waste water to 100ml / min;

[0044] (3) Sampling and analysis at the outlet of the bubbling reactor, then enter the flashing device, cool down, and centrifuge the solid salt NaCl through the desalting filter, return the concentrated solution after centrifugation to the filtering device, then enter the preheating device, and apply it to In the process, the recycling of catalytic oxidation aids is realized.

[0045] After testing, t...

PUM

| Property | Measurement | Unit |

|---|---|---|

| porosity | aaaaa | aaaaa |

| clearance rate | aaaaa | aaaaa |

| recovery rate | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com