A Reliability Evaluation Method of Electromechanical Products Combined with Manufacturing Process Data

A technology of electromechanical products and manufacturing processes, applied in the field of reliability evaluation of electromechanical products, can solve the problems of not considering the manufacturing process and unable to accurately evaluate the reliability level of batch products

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

specific Embodiment approach 1

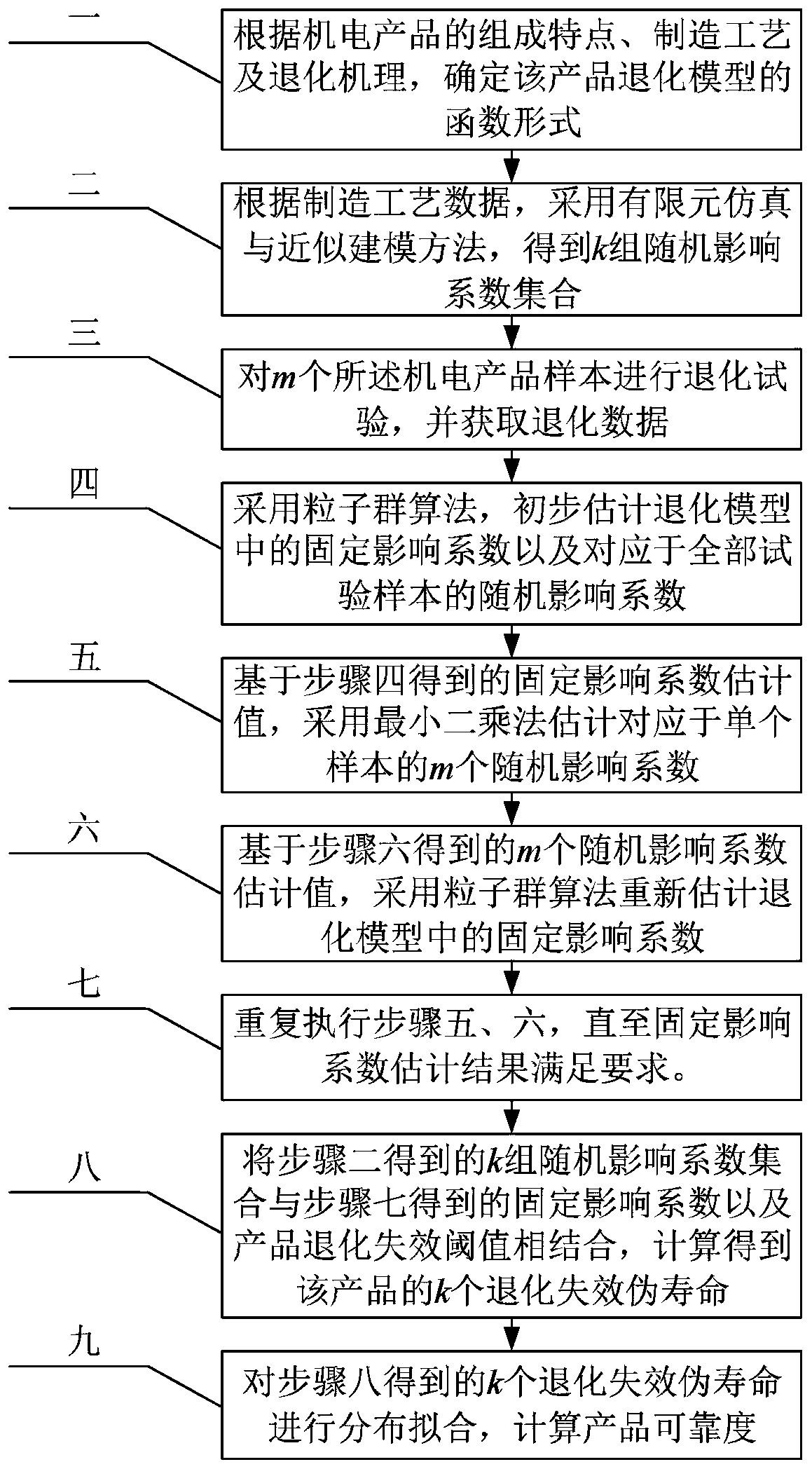

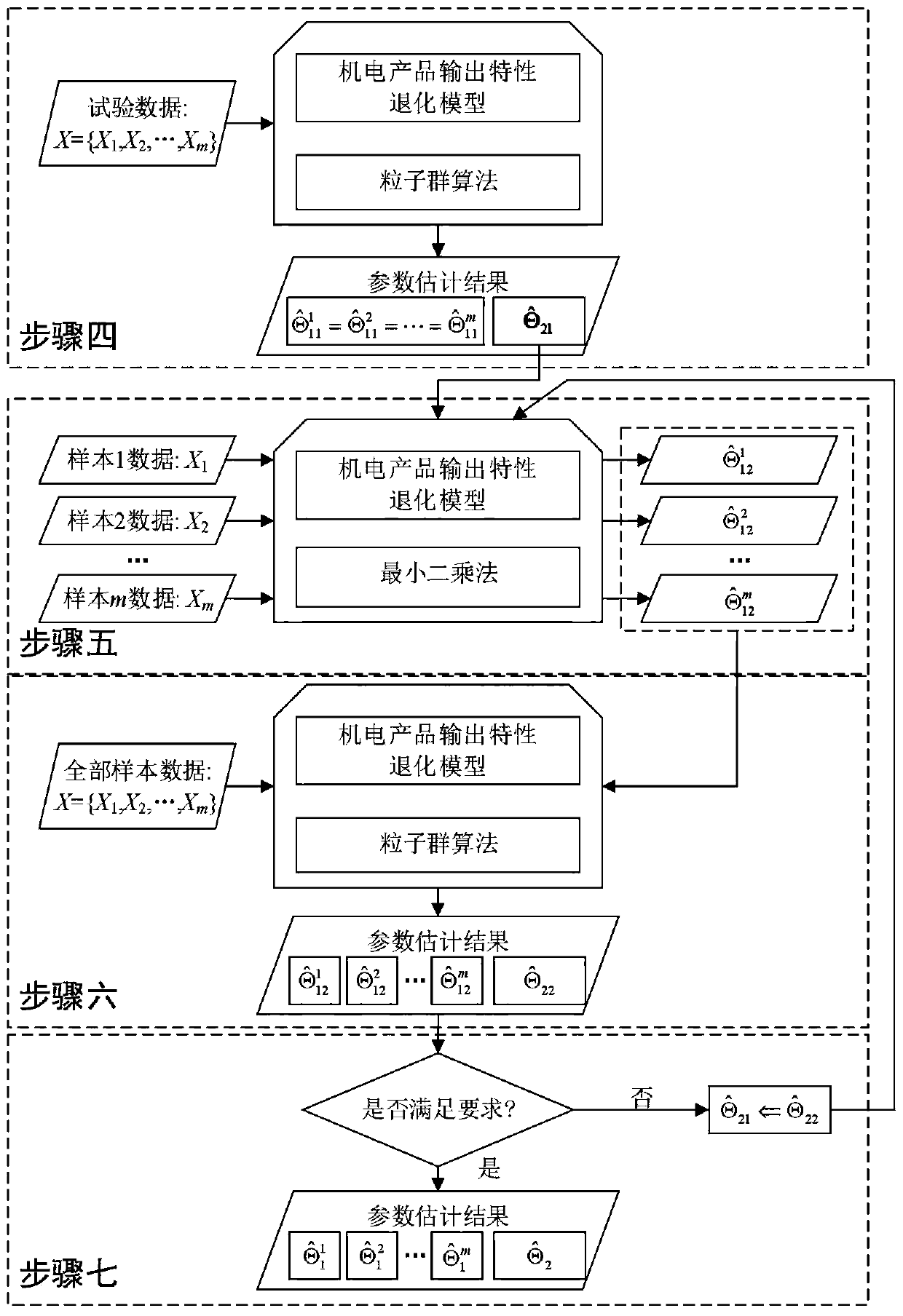

[0027] Specific Embodiment 1: This embodiment provides a method for evaluating the reliability of electromechanical products combined with manufacturing process data. The method first determines the functional form of its output characteristic degradation model according to the composition characteristics, manufacturing process data and degradation mechanism of electromechanical products. , the model includes fixed influence coefficients and random influence coefficients determined by the manufacturing process; then, based on the manufacturing process data of the electromechanical product, k random influence coefficients in the degradation model are obtained through finite element simulation and approximate modeling methods At the same time, based on the degradation data of mechanical and electrical product test samples, the value of the fixed influence coefficient in the degradation model is estimated through multiple iterations; then, according to the obtained set of k random ...

specific Embodiment approach 2

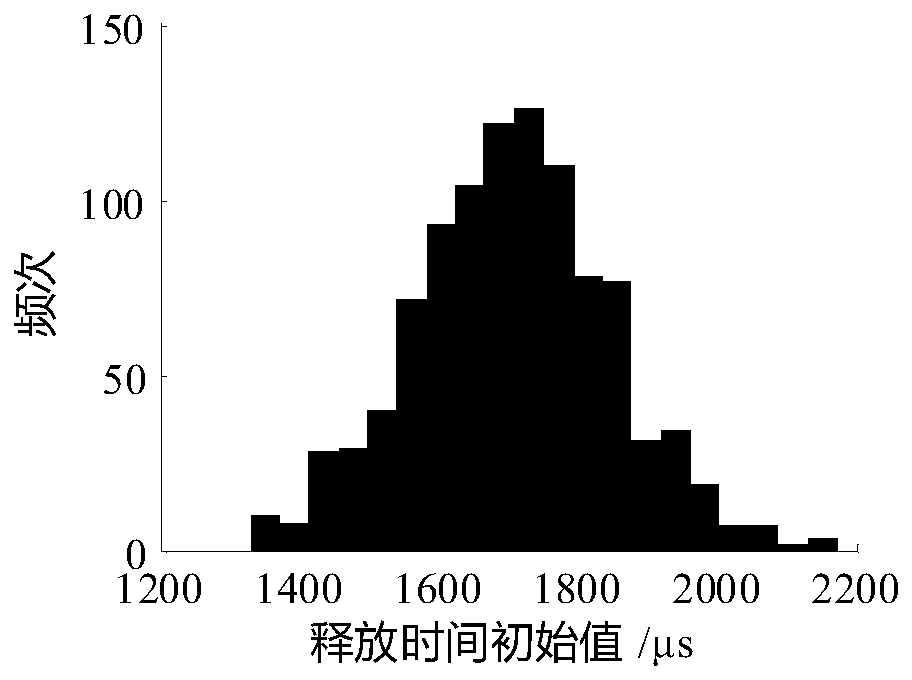

[0043] Specific implementation mode two: the following combination Figure 1 to Figure 6 This embodiment will be described, and this embodiment will further describe the first specific embodiment. In this embodiment, a certain type of electromagnetic relay is used as an object to perform reliability evaluation combined with manufacturing process data. The specific steps are as follows:

[0044] Step 1: Determine its release time T according to formula (1) and the structural characteristics, manufacturing process data and degradation mechanism of the electromagnetic relay rls (The output characteristics) The functional relationship of the degradation model is shown in formula (3).

[0045] T rls (t,T)=[T rls (0)-c][a(1.8T+491.67)(logt+C)+b]+c (3)

[0046] In the formula, T rls (t, T) is the release time value stored under the temperature stress T to the moment t; T rls (0) is the release time value at 0 moment; Θ 1 ={T rls (0), c} is the set of random influence coeffici...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com