Catalyst feeding optimal control system and method for continuous stirred tank reactor

An optimal control, decentralized control system technology, applied in general control systems, control/regulation systems, adaptive control, etc.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

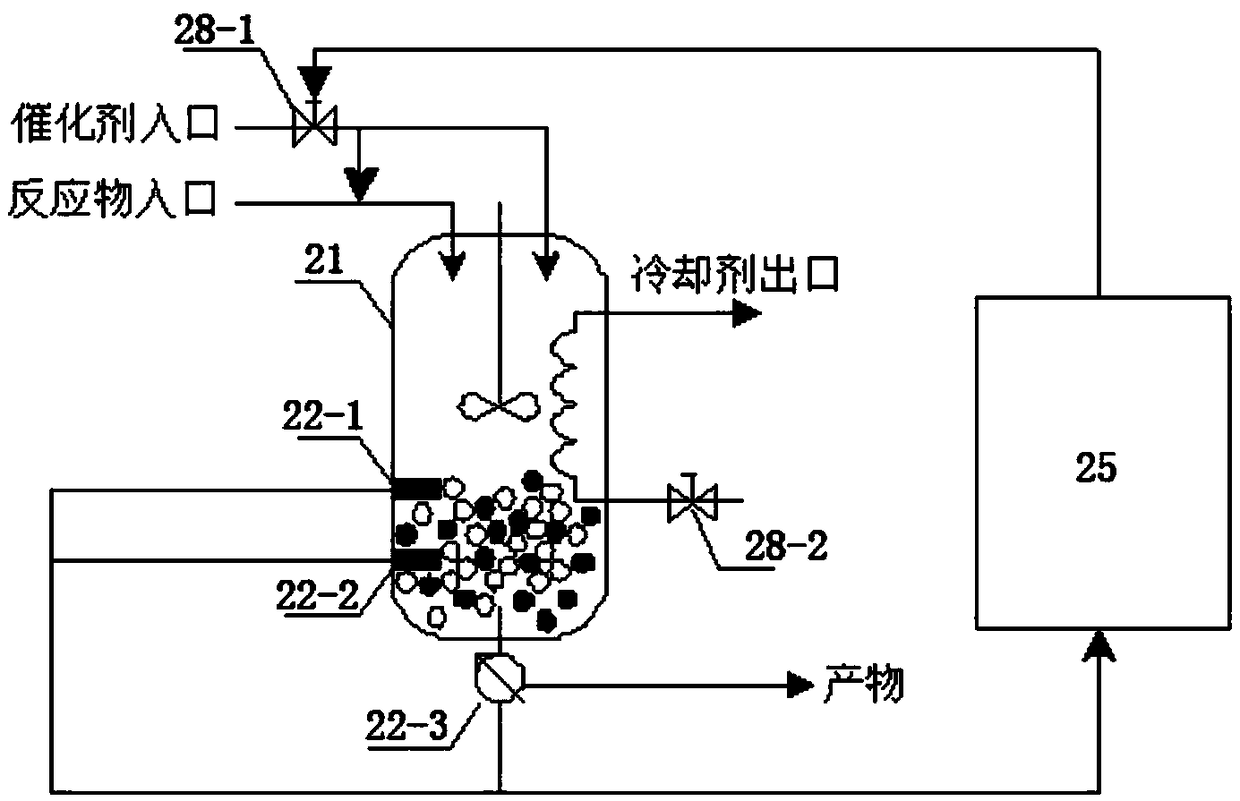

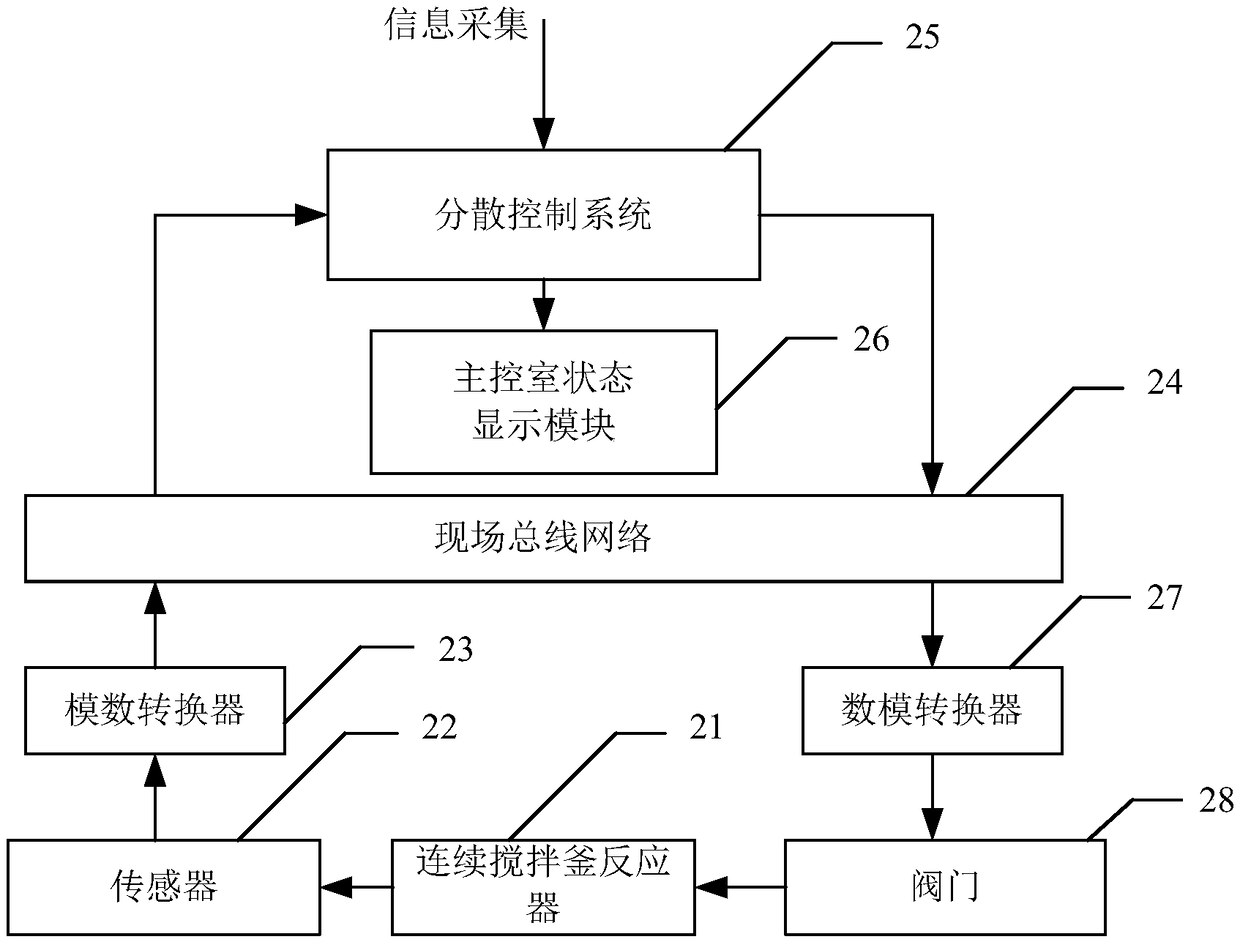

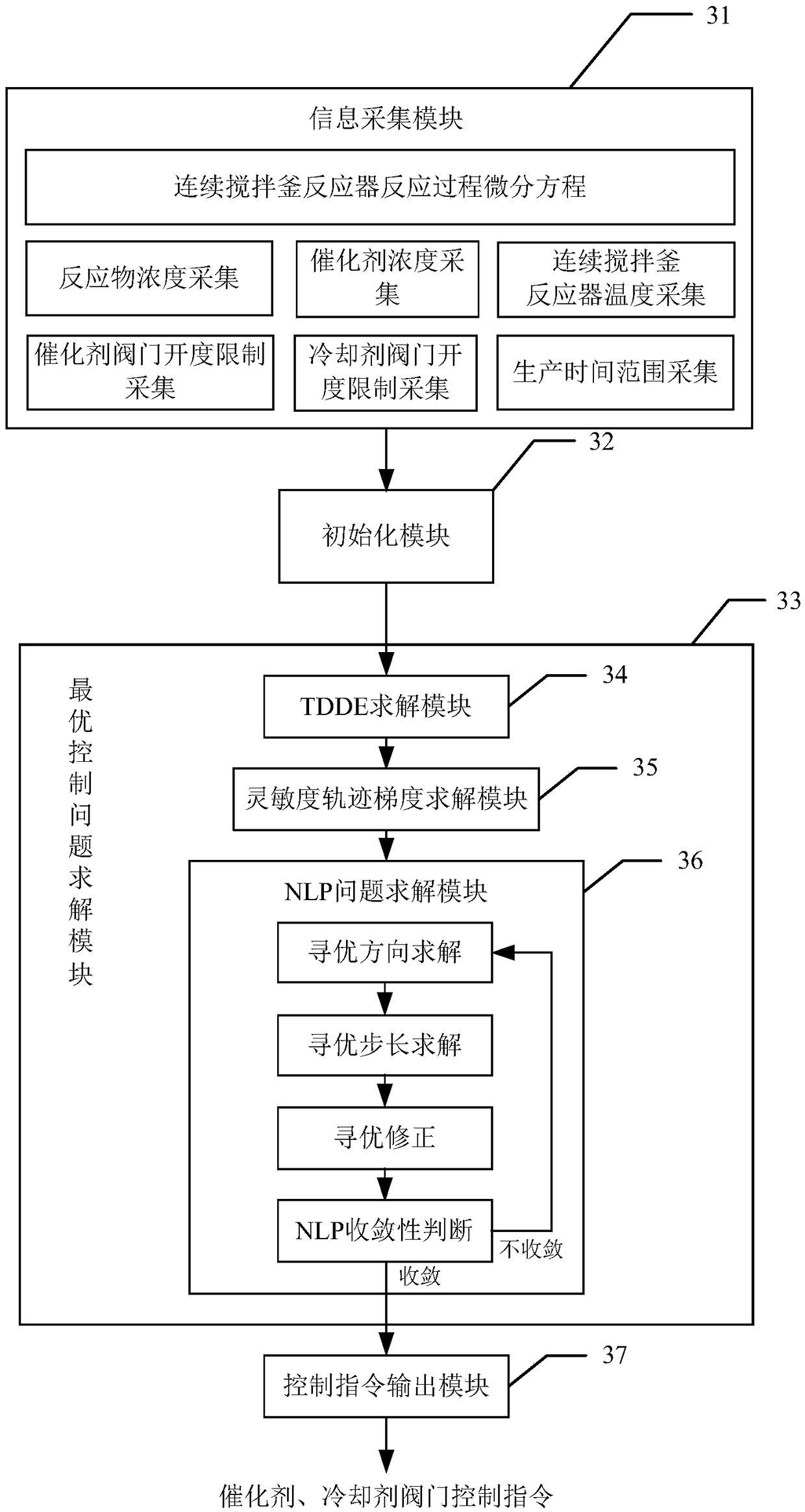

[0076] The continuous stirred tank reactor uses raw material A and catalyst B to produce chemical product C, the reaction is carried out during the stirring process of the motor, and the concentration of reactant C in the reaction process is x 1 (t) and the concentration of catalyst B x 2 (t) Mainly by controlling the opening of the reactor coolant valve u 1 (t) and catalyst feeding valve opening u 2 (t) Realization, where a proportional controller composed of coolant and reactant outlet temperature controls the internal temperature of the reactor, and the catalyst feed is divided into direct input 0.1u 2 (t) and mixed input with delay 0.9u 2 (t-s) two parts, the duration of the production process is 0.2 hours, the opening range of the catalyst control valve is -1 to 1, and the opening of the coolant control valve is -2 to 2. The optimal control requirement of the production process is to obtain The catalyst and coolant valve control strategy that minimizes the amount of ca...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com