Special-shaped workpiece detection device

A technology for detection devices and special-shaped workpieces, which is applied in the direction of measuring devices, manufacturing tools, instruments, etc., can solve the problems of uncertain number of workpieces, workpiece lodging, and uncertain number of workpieces, and achieve the effects of reducing the number of workers, reducing costs, and saving time

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0013] Specific examples of the present invention are given below. The specific embodiments are only used to further describe the present invention in detail, and do not limit the protection scope of the claims of the present application.

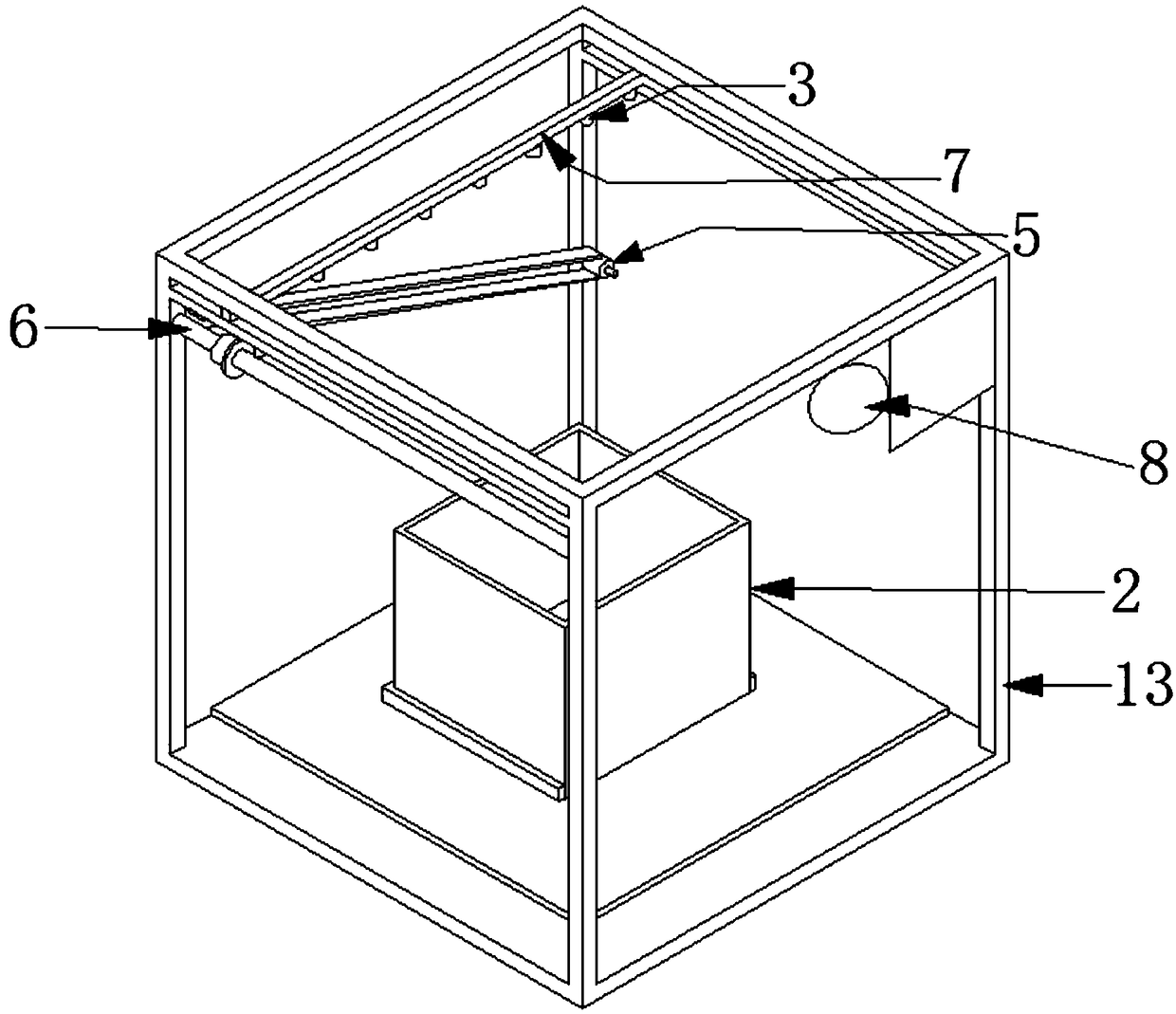

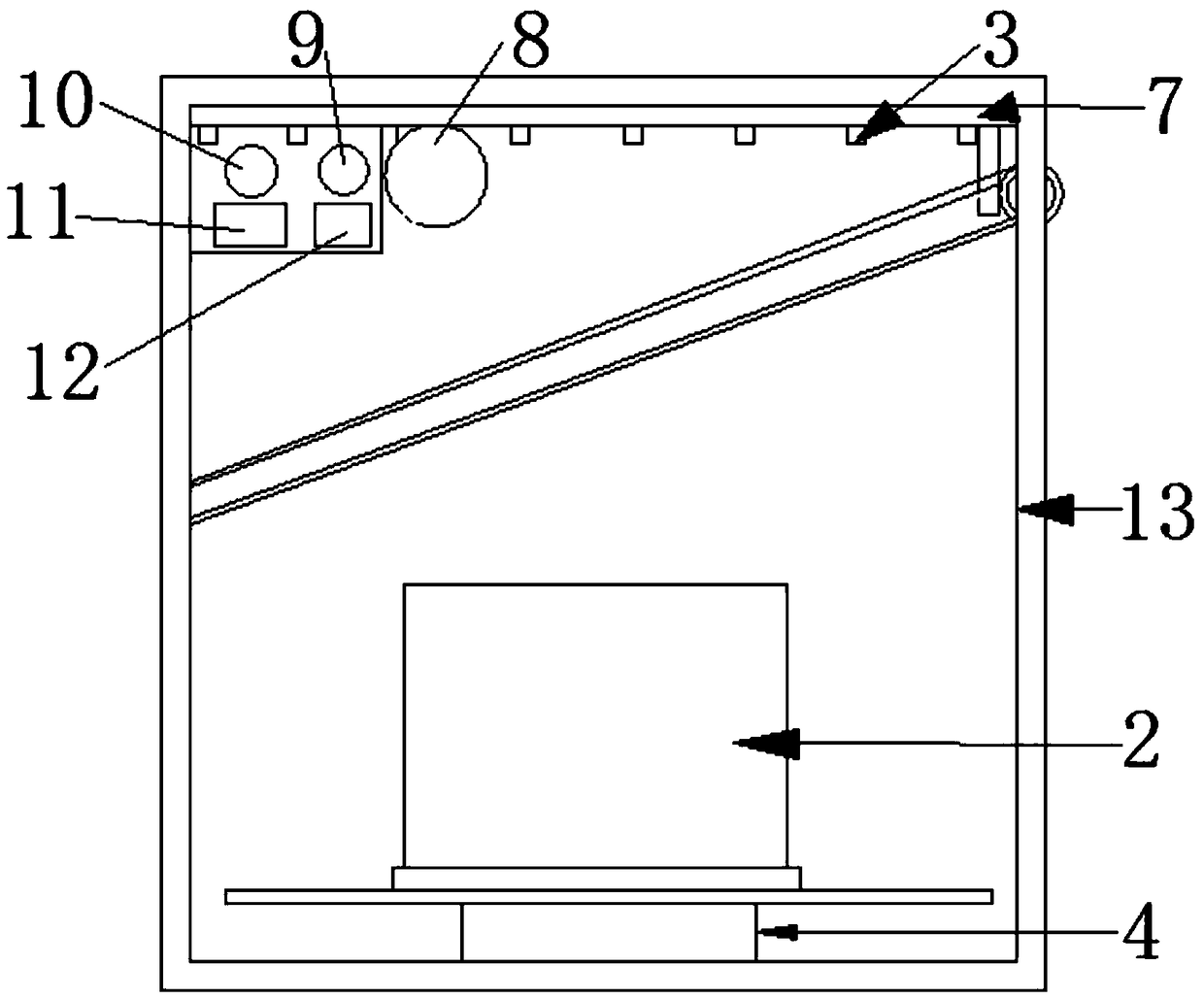

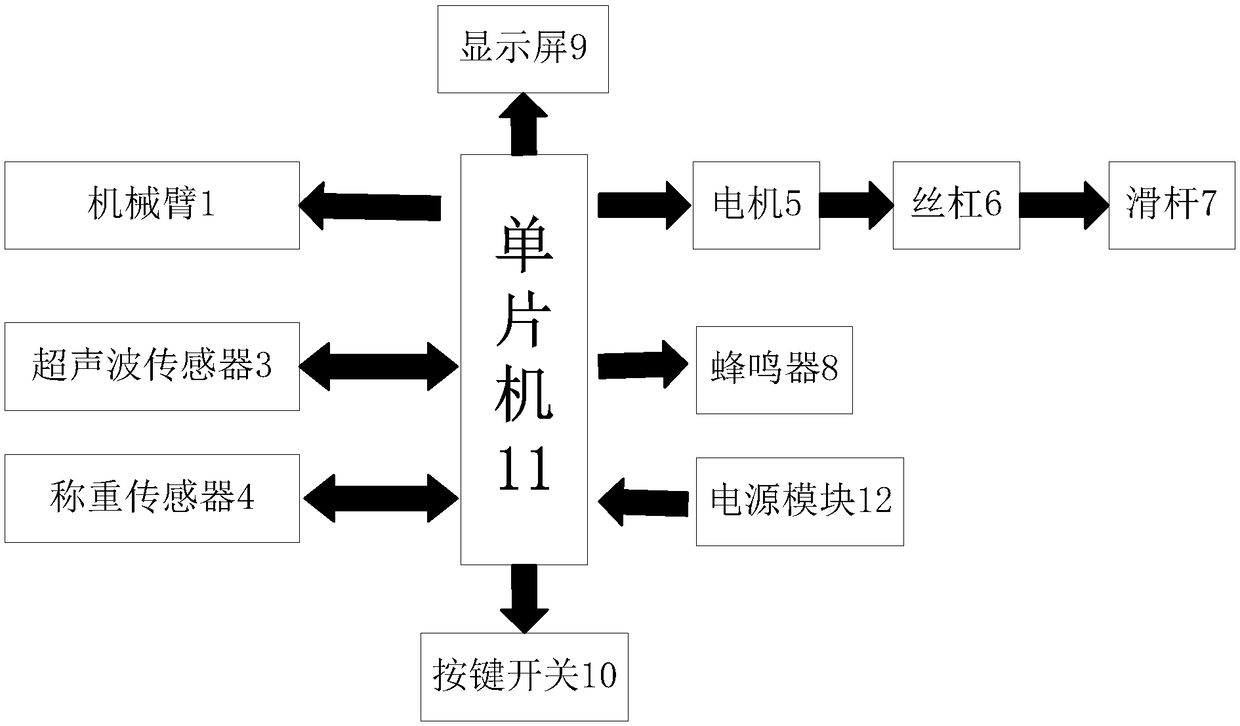

[0014] The invention provides a special-shaped workpiece detection device (see Figure 1-3 , referred to as the device), which is characterized in that the device includes a mechanical arm 1, a transfer box 2, an ultrasonic sensor 3, a load cell 4, a motor 5, a screw 6, a slide rod 7, a buzzer 8, a display screen 9, and a key switch 10. Single-chip microcomputer 11, power supply module 12 and frame 13;

[0015] Described frame 13 is the main body casing of device; Described slide bar 7 is installed on frame 13 upper ends, and its one end is installed on frame 13 by track, and the other end is installed with the nut that cooperates with lead screw 6; Several ultrasonic sensors 3 are installed on On the slide bar 7, it is used to measure th...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com