Feeding and heating device for automobile carpets

A technology for heating devices and car carpets, which is applied in heating/cooling fabrics, conveyors, transportation and packaging, etc. It can solve the problems of high intensity of human labor, uneven heating of carpets, and reduced production efficiency, and achieves simple structure and easy use Flexibility, efficiency-enhancing effects

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0017] In order to make the technical means, creative features, goals and effects achieved by the present invention easy to understand, the present invention will be further described below in conjunction with specific embodiments.

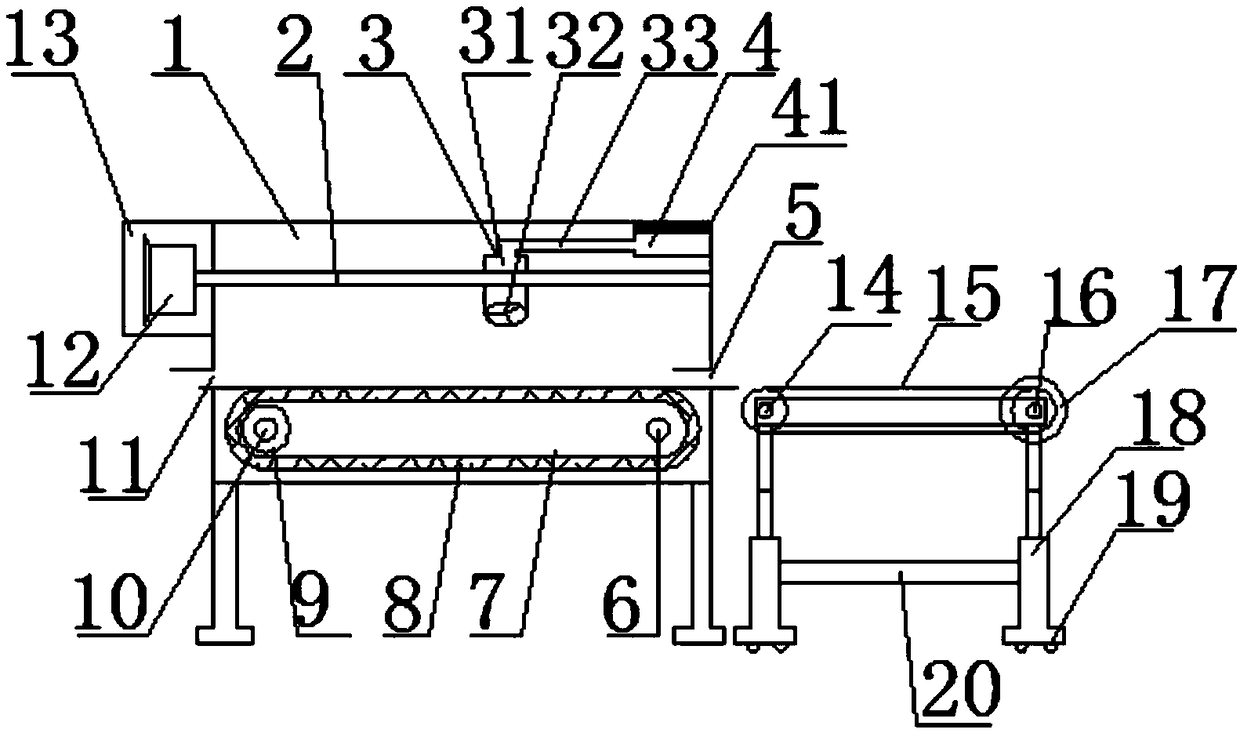

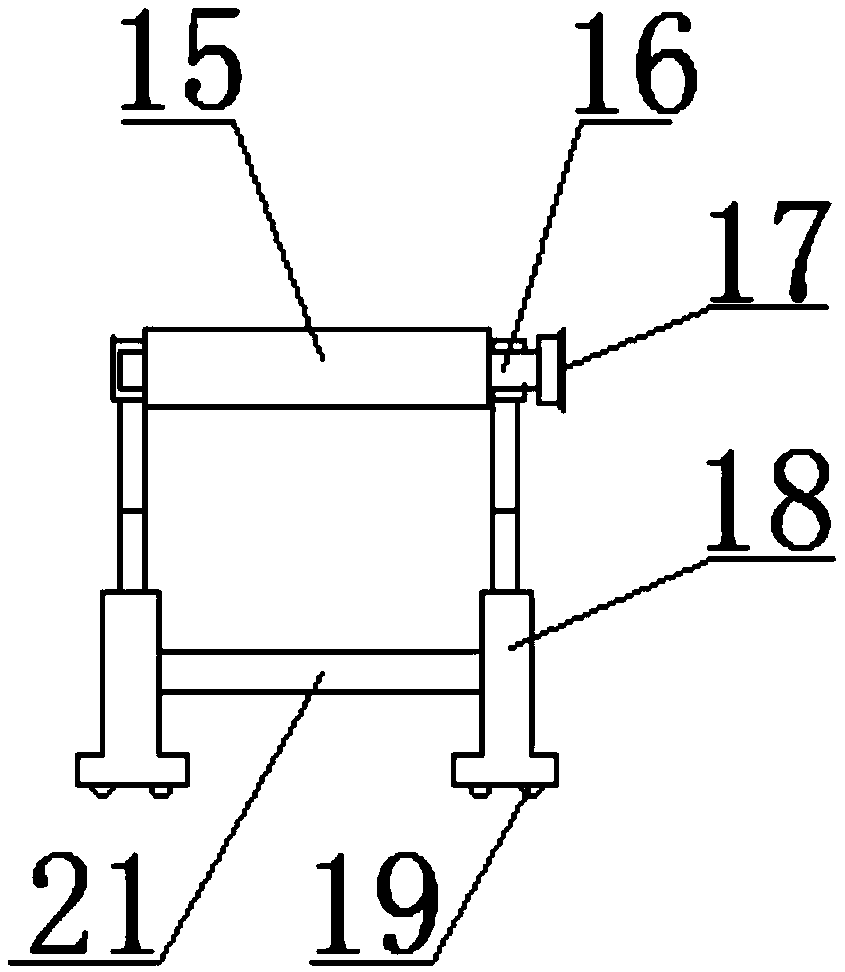

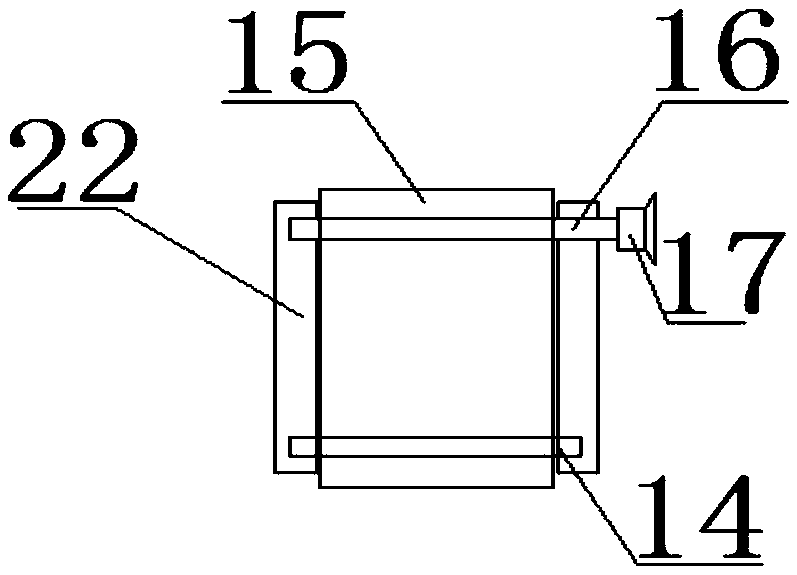

[0018] Such as Figure 1 to Figure 3 As shown, a feeding heating device for automobile carpets includes a heating device and a feeding device. The heating device includes a heating box 1, a dust collection device 3, a screw rod 2, a dust storage box 4, and a transmission mechanism. Both sides of the heating box 1 are respectively provided with a feed port 5 and a discharge port 11, the dust storage box 4 is arranged on the top of the heating box 1, and the outside of the heating box 1 is provided with a drive motor 2 12, and the The screw mandrel 2 is arranged on the upper part of the heating box 1, the driving motor 2 12 is connected with the screw mandrel 2 through a coupling, and the transmission mechanism is horizontally arranged in the heatin...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com