Locking connecting mechanism for bus groove assembly production line

A connection mechanism and busway technology, applied in metal processing, metal processing equipment, manufacturing tools, etc., can solve problems such as potential safety hazards, inability to meet the needs of intelligent automatic control, and cumbersome processes

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

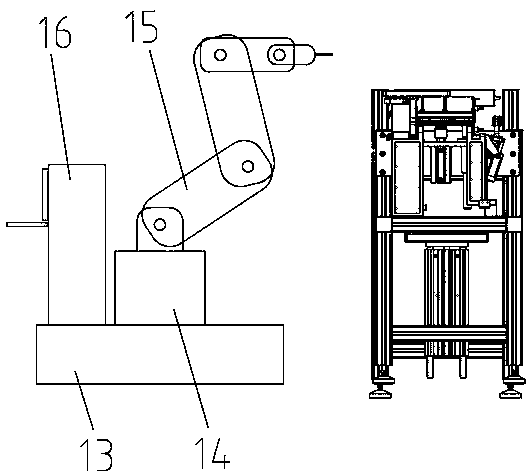

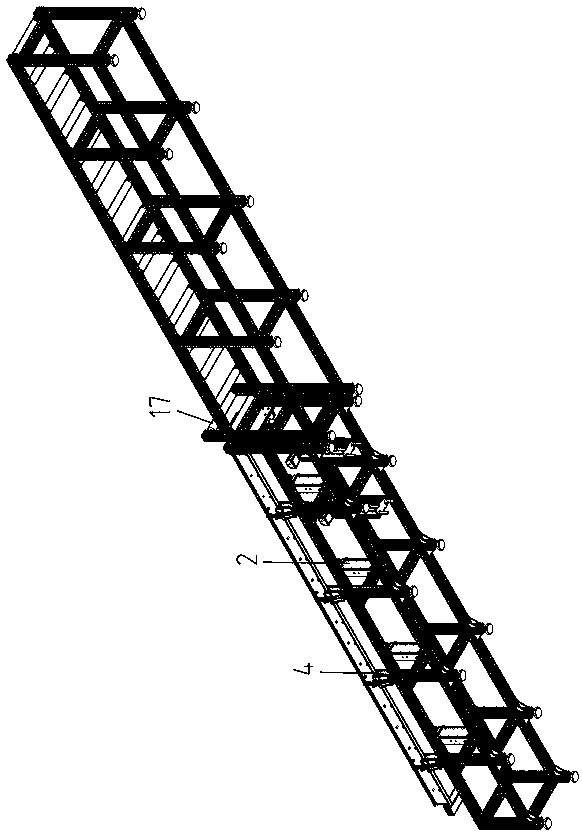

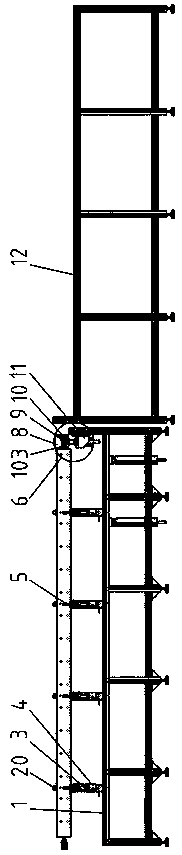

[0019] As shown in the figure, a locking connection mechanism for a bus duct assembly production line includes a chassis, which is divided into an assembly section 1 located in the front section and a conveying section 12 located in the rear section along the length direction. The conveyor section 12 chassis A number of horizontal conveying rollers 121 are arranged side by side and evenly distributed on the upper surface; on both sides of the upper part of the assembly section 1 are arranged a number of first limit support columns 2 and second limiters that can respectively limit and support the folded edges and side plates of the upper and lower cover plates of the bus duct products. The limit support column 4, the top of the first limit support column 2 is provided with a pressure rod 20, the pressure rod 20 extends laterally to the top of the busway product, and the pressure rod 20 is connected with a side plate capable of pressing the busway product from top to bottom. Pres...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com