Road finisher with heating element for screed

A heating element, electric heating element technology, applied in the direction of roads, roads, road repair, etc., to achieve the effect of improving work and production quality, preventing material weakening, and preventing efficacy

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

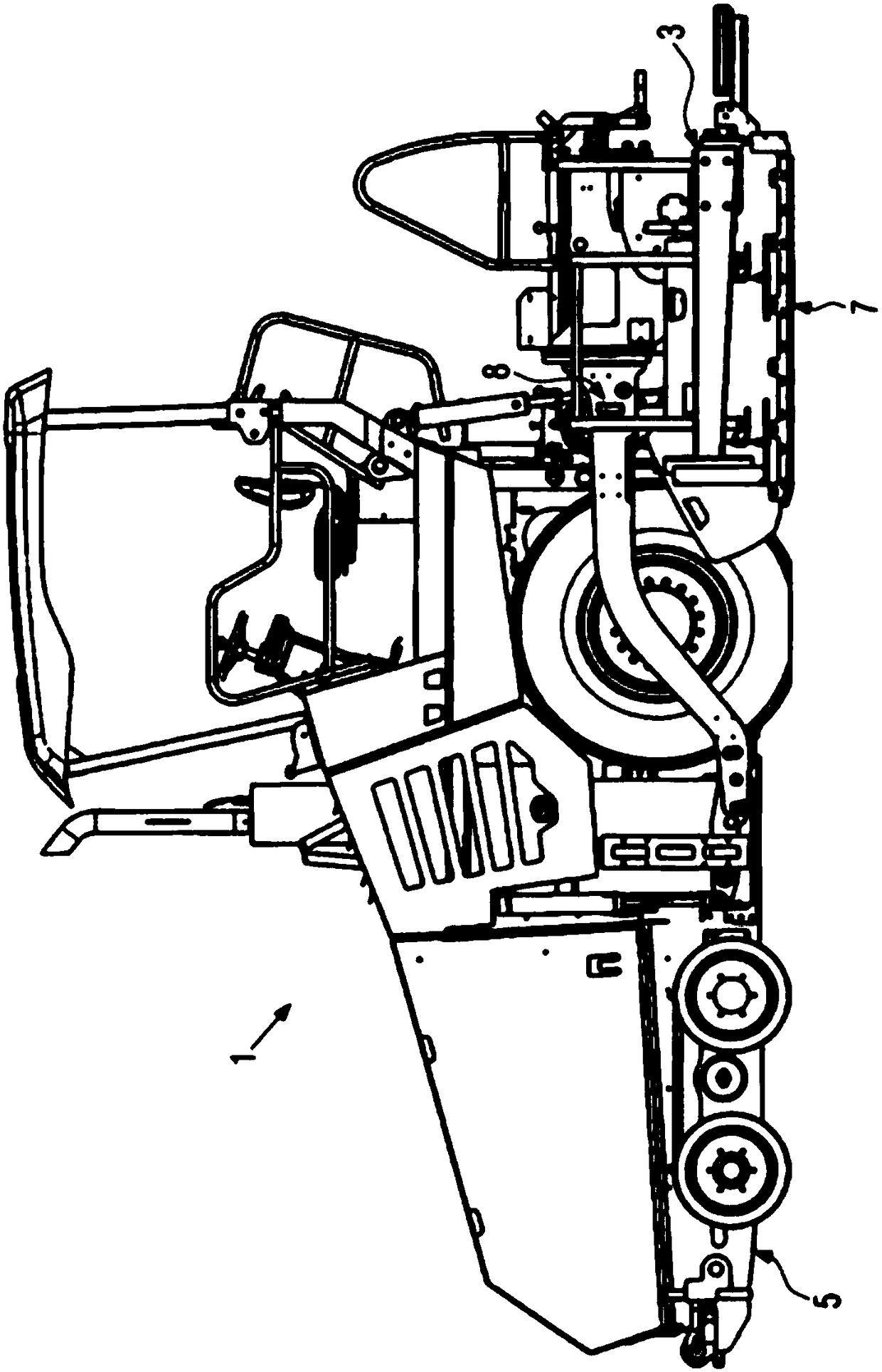

[0031] figure 1 An exemplary embodiment of a road paver 1 according to the invention with a heatable screed 3 and a tractor 5 is shown schematically. Different types of screeds 3 can be replaceably attached to the tractor 5 via a fastener mechanism. On the underside of the screed 3 there is a compacting unit 7 which converts the paving material into a flat and firm paving surface. A weight sensor 8 is attached to the suspension of the screed 3 at the tractor 5 , which can be used to determine the screed configuration from known weight values of different models of screed 3 .

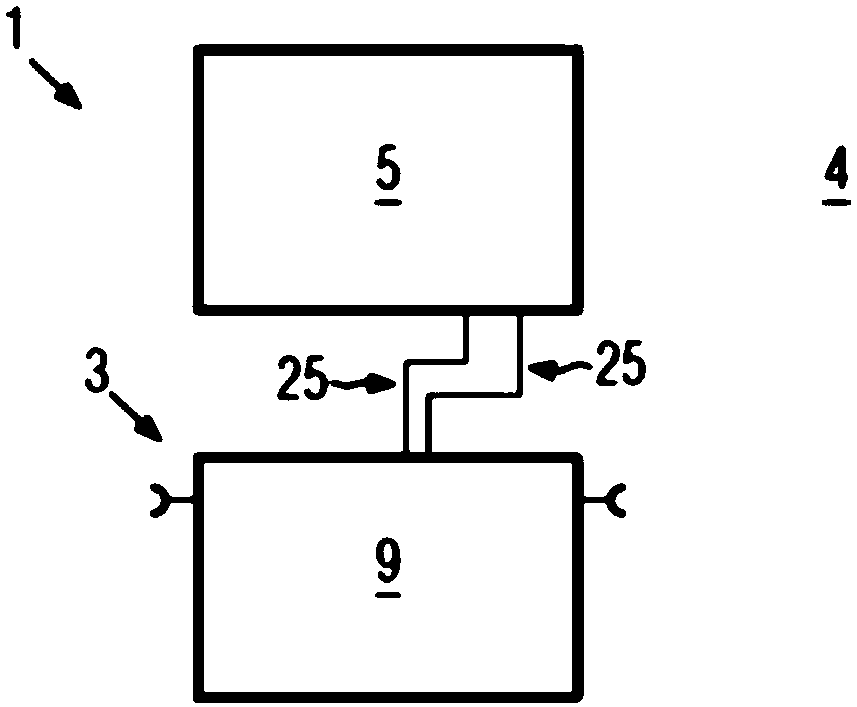

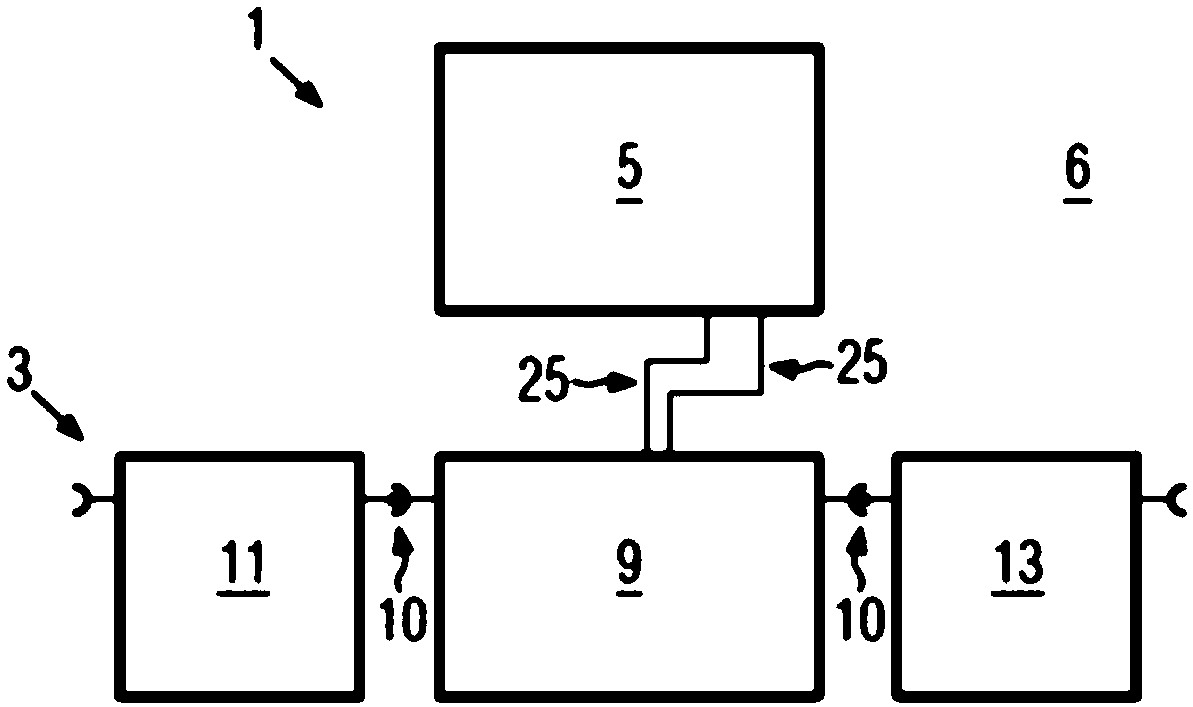

[0032] figure 2 A schematic diagram showing an exemplary embodiment of a road paver 1 according to the invention with a heatable screed 3 in a first screed configuration comprising a basic screed 9 . Two power lines 25 run from the tractor 5 to the basic screed 9 and are mainly used to provide power for screed heating and due to the two-wire design of the power lines 25 are already adapted to suppl...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com