Automatic pipe fitting punching equipment

A technology of punching and pipe fittings, which is applied in the field of automatic pipe punching equipment and appliances, can solve the problems of reducing product yield, punching errors, and inability to improve accuracy, and achieve the effect of improving yield and accuracy and improving production efficiency

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

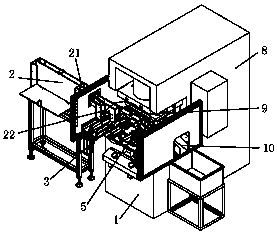

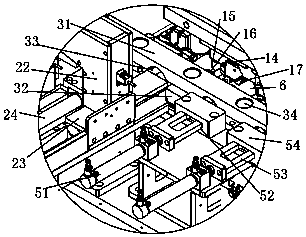

[0011] Combine below Figure 1 to Figure 2 Specific description embodiment:

[0012] Automatic pipe punching equipment, including a frame 1, is characterized in that, the frame 1 is provided with a slide rail, and the slide rail is provided with a punching mold frame 3, and the punching mold frame 3 passes through The cylinder can slide on the slide rail. The punching mold base 3 includes an upper mold base 31 and a lower mold base 32. A pipe groove 33 is formed in the middle of the upper mold base and the lower mold base. A punching hole 34 is provided on the upper mold base; One side of the punching formwork is provided with a feeding mechanism 2 and a limit mechanism 5, and the feeding mechanism 2 includes a dual-channel conveying trough 21, and the end of the dual-channel conveying trough 21 is connected with a vertical feeding channel 22 , the bottom of the vertical feeding channel 22 is connected with a feeding trough 23, and a pushing slide plate 24 is arranged in the ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com