Single auxiliary elevator self-locking bolt

An elevator and self-locking technology, applied in the direction of load hanging components, transportation and packaging, can solve the problem of unsafe bolt loosening, and achieve the effects of simple structure, high reliability and safety, and convenient and fast operation.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

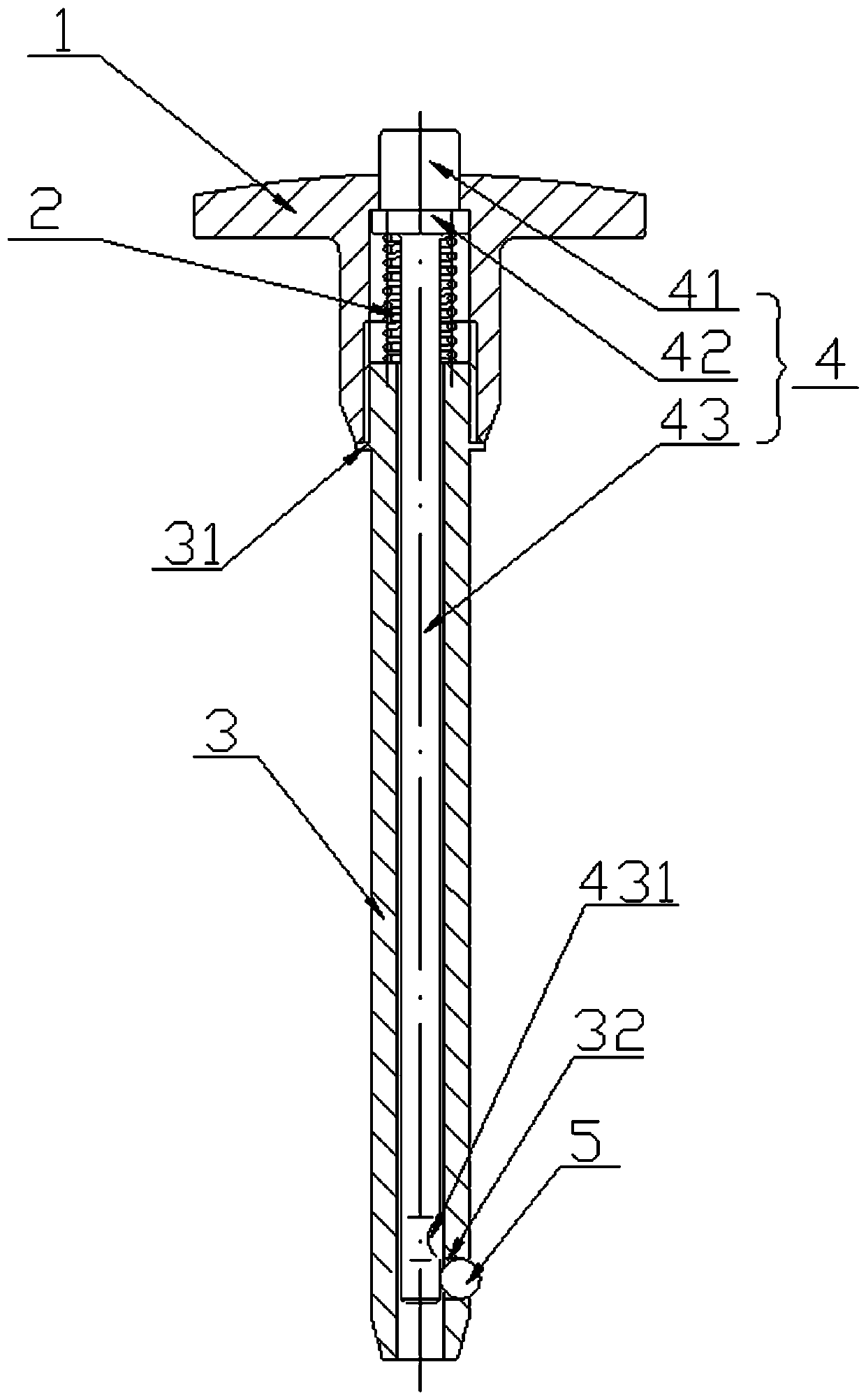

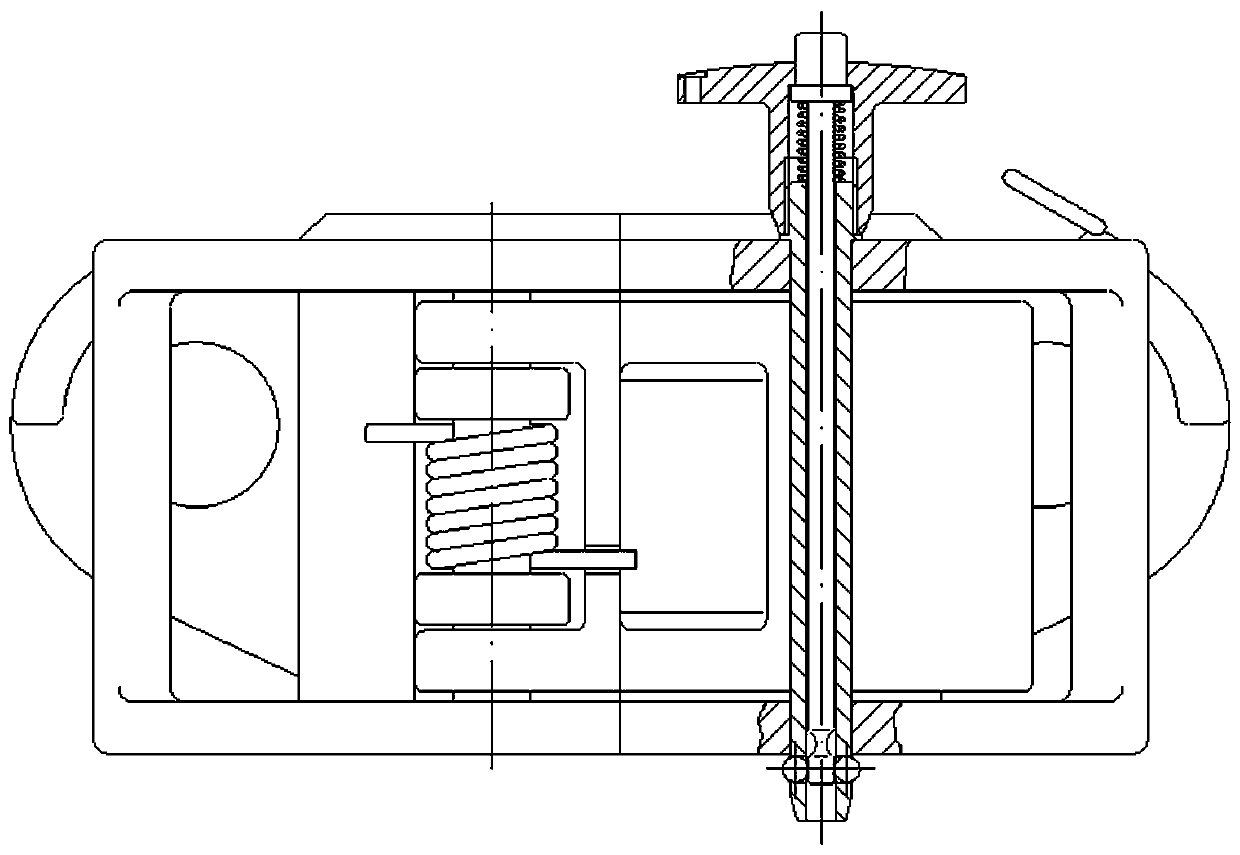

[0021] Such as figure 1 As shown, a single auxiliary elevator self-locking bolt includes a handle 1, a spring 2, a threaded pin 3, a lower pressure rod 4 and a steel ball 5, a snap ring 31 is arranged on the outside of the threaded pin 3 above, and the threaded pin 3 The lower end is provided with a ball position through hole 32 at one side, and the lower pressing rod 4 includes a hand pressing part 41, a limiting part 42 and a main rod part 43 from top to bottom, and the lower end of the main rod part 43 is arranged on one side. There is a steel ball slot 431, the steel ball 5 is placed in the ball position through hole 32, the lower pressure rod 4 is placed in the threaded pin 3, the spring 2 is set outside the top of the main rod part 43 of the lower pressure rod 4, and is located on the threaded pin 3 and the limit portion 42 of the lower pressure rod 4, the handle 1 is clamped outside the threaded pin 3 and fixed together by threaded connection, and the bottom end of the...

Embodiment 2

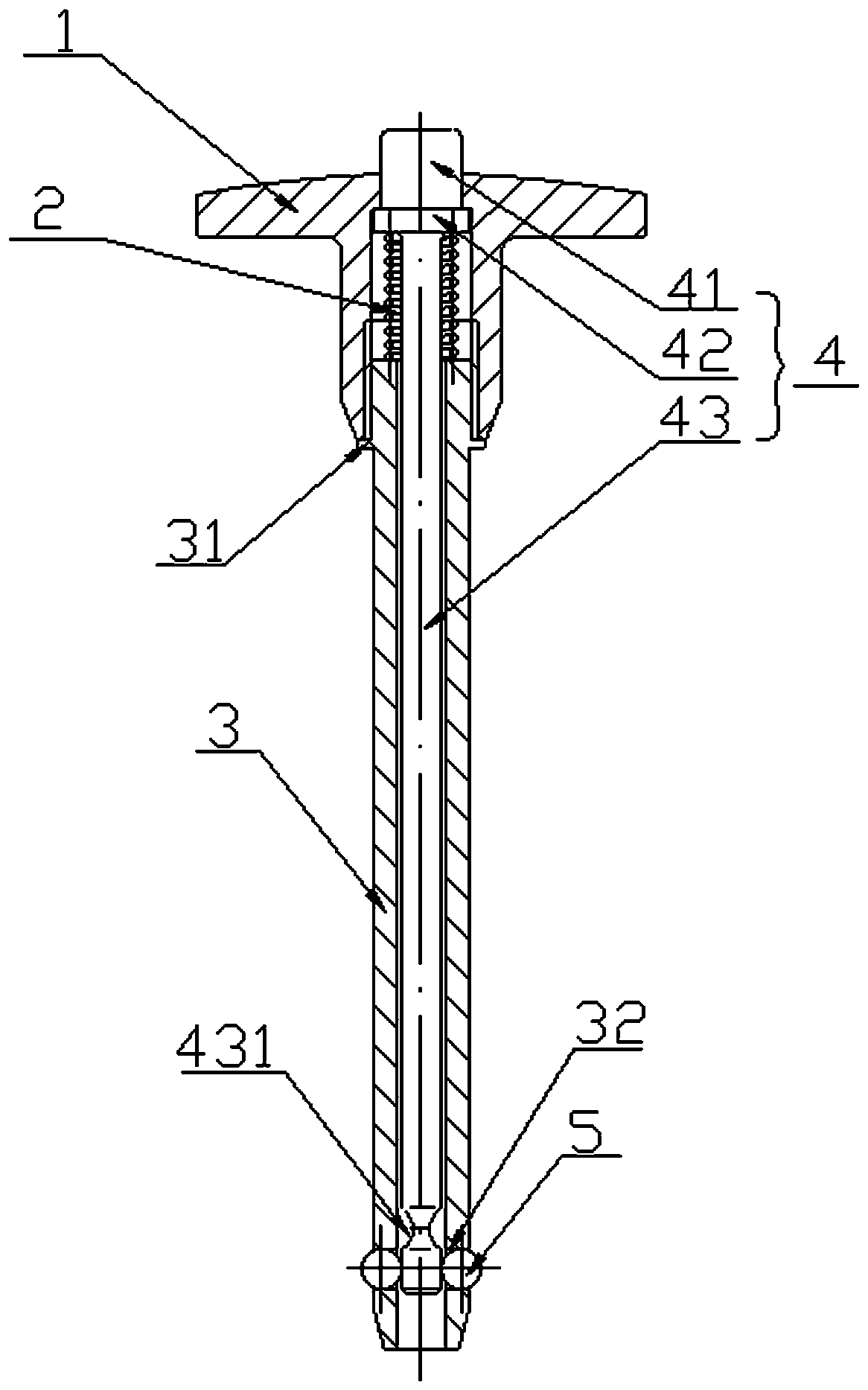

[0023] Such as figure 2 As shown, a single auxiliary elevator self-locking bolt includes a handle 1, a spring 2, a threaded pin 3, a lower pressure rod 4 and two steel balls 5, a snap ring 31 is arranged on the outside of the threaded pin 3 above, and the threaded pin 3 The lower end is provided with two opposite ball position through holes 32 at the positions on both sides. The lower pressing rod 4 includes a hand pressing part 41, a limiting part 42 and a main rod part 43 in order from top to bottom. The lower end of the main rod part 43 is located at There are two opposite steel ball slots 431 on both sides, the two steel balls 5 are respectively placed in the two ball position through holes 32, the lower pressing rod 4 is placed in the threaded pin 3, and the spring 2 is set on the lower pressing rod 4 outside the top of the main rod part 43, between the threaded pin 3 and the limit part 42 of the lower pressure rod 4, the handle 1 is clamped outside the threaded pin 3, f...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com