Attitude angle control method of three-degree-of-freedom parallel mechanism

A control method and attitude angle technology, which can be applied in the direction of control without feedback, which can solve the problems of difficult attitude control and low precision of parallel mechanisms.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

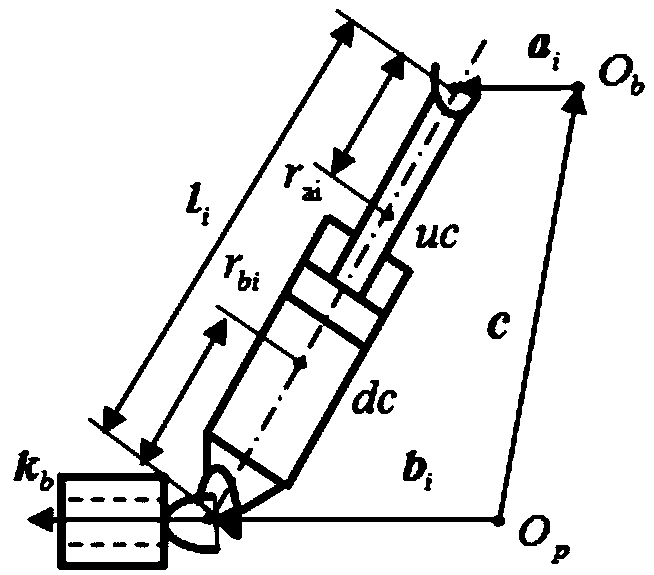

[0060] In the embodiment, the parallel mechanism includes three sets of actuators, three sets of support rods and a moving platform, one end of the three sets of actuators is respectively hinged to the moving platform, and the other ends of the three sets of actuators are respectively hinged to the foundation or the support rods; One end of the three sets of support rods is respectively hinged to the foundation, and the other ends of the three sets of actuators are respectively hinged to the moving platform or the actuator;

[0061] When the parallel mechanism is in the initial working position: the actuator, the support rod and the upper hinge point of the moving platform are in the same plane and located on a circle; the three support rods have the same length and are located on a circle with the lower hinge point of the foundation The center of the circle where the upper and lower hinge points are located is the vertical projection of the center of the moving platform on the...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com