Tooth distribution system for milling wheel of double-wheel slot milling machine

A double-wheel milling and milling wheel technology, which is applied in earth movers/excavators, construction, etc., achieves the effects of small wear of milling teeth, wide application range of rock strata, and improved rock breaking efficiency and milling speed

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

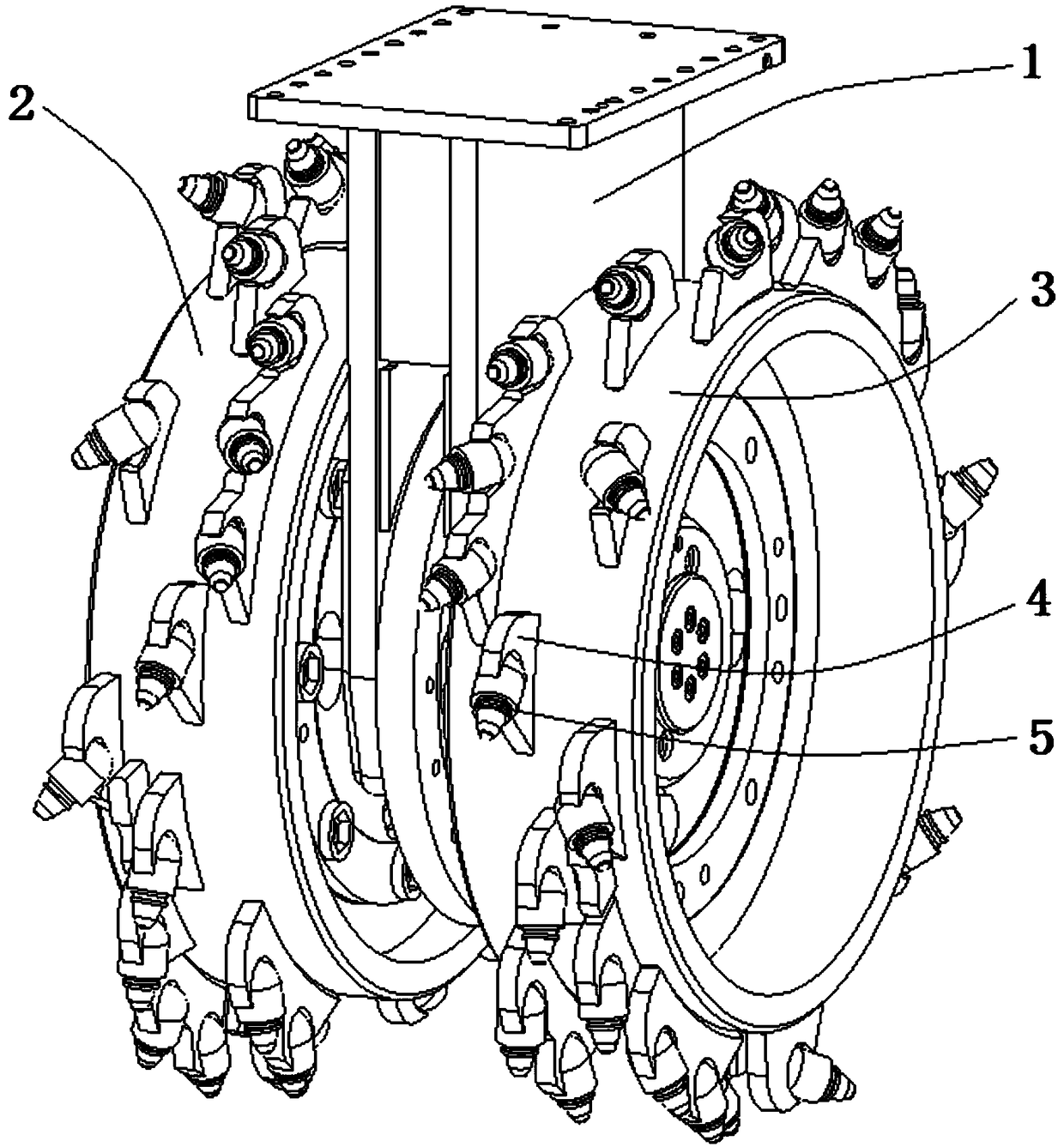

[0031] see figure 1 , shows the milling wheel tooth arrangement system of the double-wheel milling machine of the present invention.

[0032] The milling wheel gear arrangement system of the double-wheel milling machine includes a milling wheel main body 1, and a tooth seat plate 4 is positioned on the left wheel hub 2 and the right wheel hub 3 of the milling wheel main body 1, and a plurality of tooth seat plates are welded and fixed on the tooth seat plate 4. Pick 5, a plurality of picks 5 are symmetrically arranged on the left hub 2 and the right hub 3 according to the tooth distribution rule, the positioning position of the tooth seat plate 4 is determined according to the spatial positioning position of the pick 5, the pick 5 The spatial positioning of the pick is determined by the spatial angle between the sharp point of the pick and the axis of rotation of the pick.

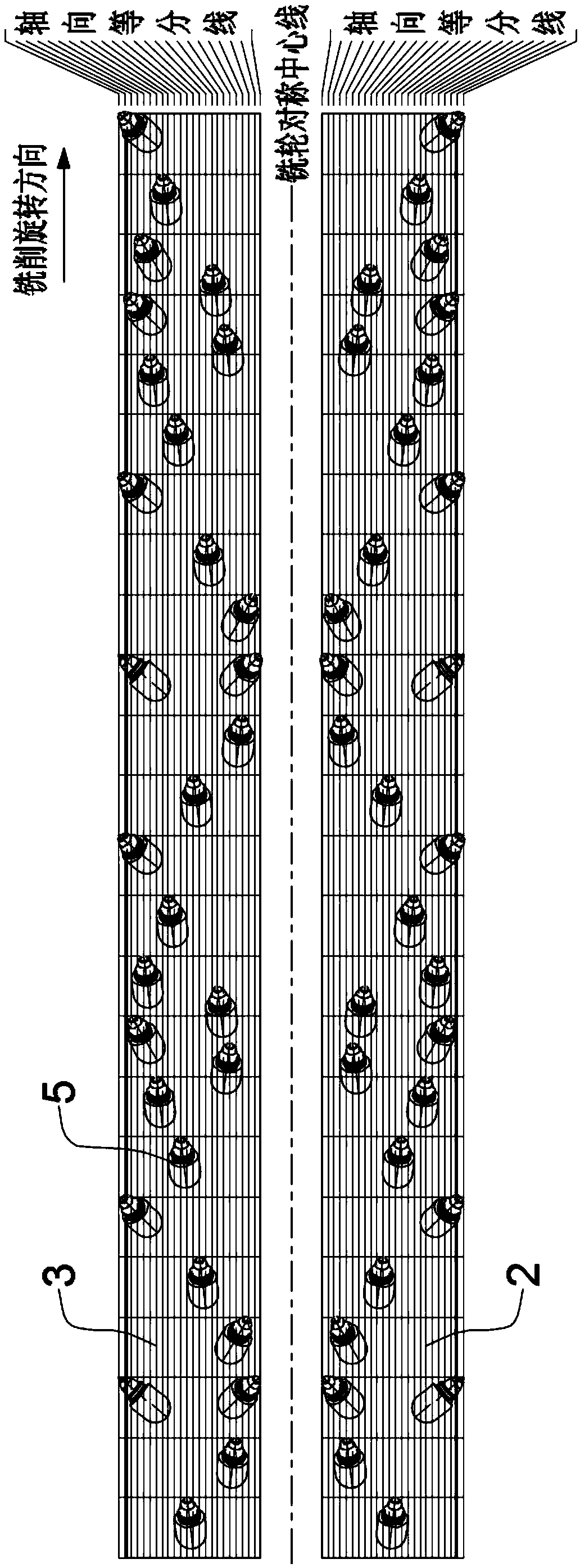

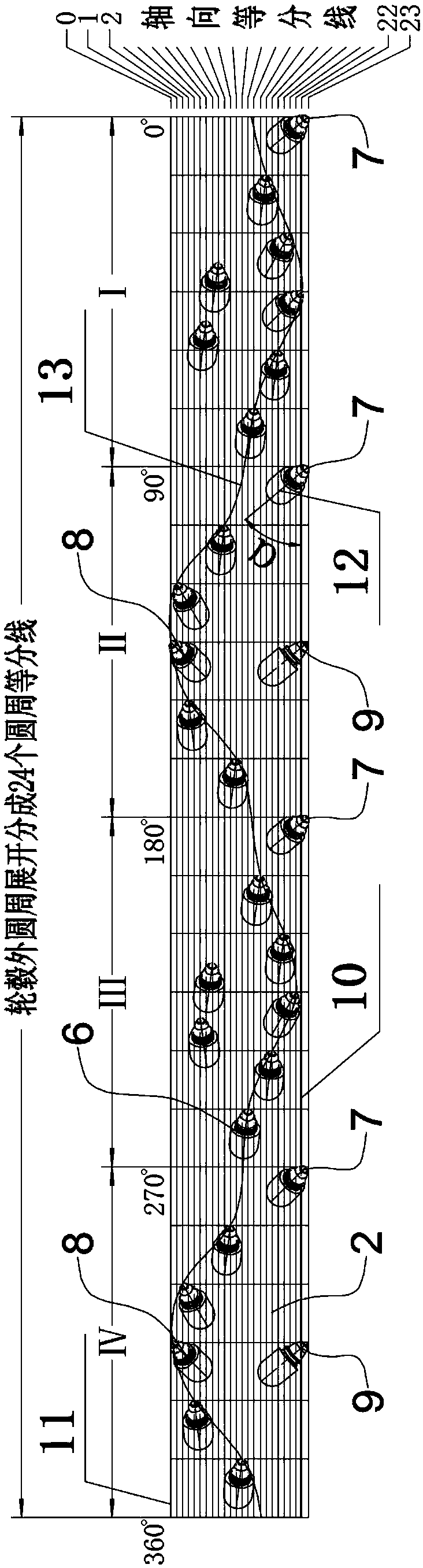

[0033] refer to figure 2 , shows a schematic diagram of the symmetrical arrangement of the picks 5 o...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com