Self-supporting homogeneous forward osmosis membrane capable of eliminating internal concentration polarization and its preparation method and application

A forward osmosis membrane, self-supporting technology, applied in chemical instruments and methods, semi-permeable membrane separation, membrane, etc., can solve problems such as difficult cleaning, internal concentration polarization, membrane fouling, etc., and achieve easy cleaning and good stability , Strong anti-fouling and anti-bacterial properties

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

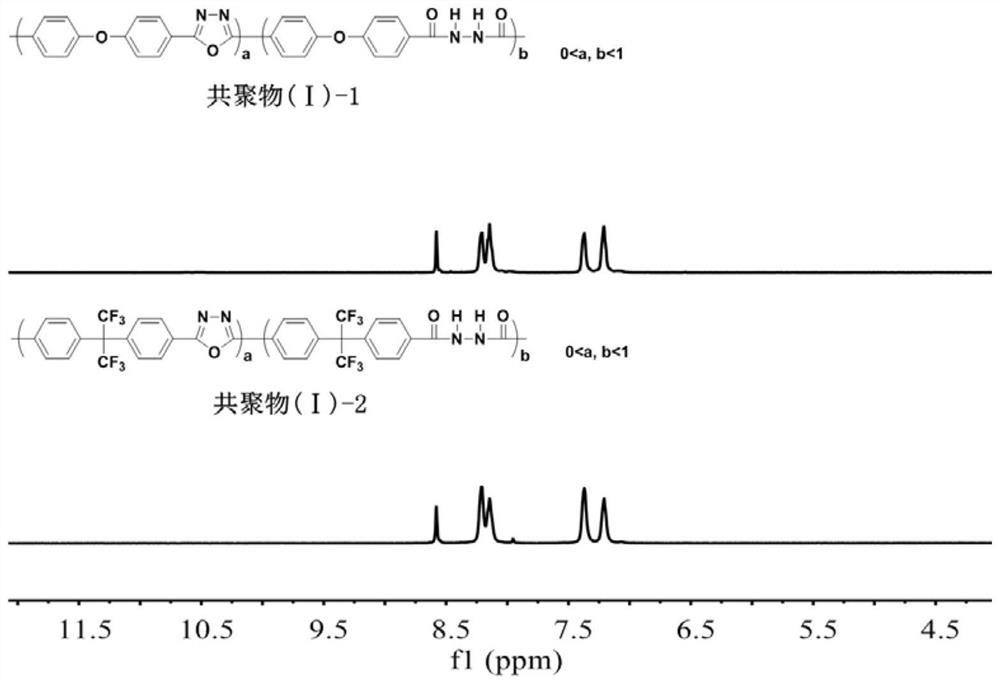

[0042] Preparation of copolymer (I)-1

[0043] Pour 4.0010g of dicarboxydiphenyl ether into an appropriate amount of polyphosphoric acid, stir at 100°C for 1 hour; add hydrazine sulfate (2.4188g) into the reaction system, the molar ratio of hydrazine sulfate to dicarboxydiphenyl ether monomer is 1.2:1, Raise the temperature to 160°C, and react at high temperature for 6 hours; pour the viscous solution into 5wt% NaOH solution to precipitate, wash until neutral, and dry in vacuum for later use to obtain 3.4376g of a brownish yellow solid with a yield of about 93.56%; from figure 1 According to NMR and IR spectra, the copolymer (I)-1 was successfully synthesized.

[0044]

Embodiment 2

[0046] Preparation of copolymer (I)-2

[0047] Pour 4.0031g of bis(4-carboxyphenyl)hexafluoropropane into an appropriate amount of polyphosphoric acid, stir at 100°C for 1h; add hydrazine sulfate (1.5908g g) into the reaction system, hydrazine sulfate and bis(4-carboxyphenyl) The molar ratio of hexafluoropropane monomer was 1.2:1, and the reaction was carried out at 160°C for 6 hours; the viscous solution was poured into 5wt% NaOH solution to precipitate, washed to neutrality, and vacuum-dried for later use to obtain 3.2576 g of a brownish-yellow solid with a yield of about 86.20%; from figure 1 According to NMR and IR spectra, the copolymer (I)-1 was successfully synthesized.

[0048]

[0049] Depend on figure 1 The nuclear magnetic pattern of can prove that copolymer (I) has been successfully synthesized.

Embodiment 3

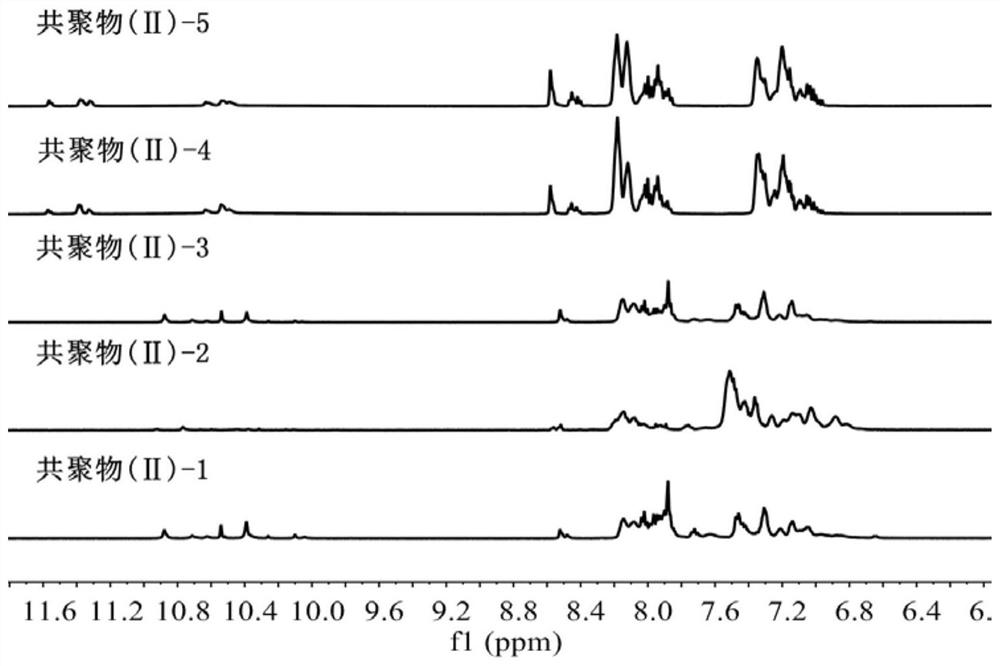

[0051] Preparation of copolymer (II)-1

[0052] 0.6012g copolymer (I)-1 was dissolved in NMP, the system concentration was 5wt%, and a small amount of PPA was added to the reaction system; after the polymer was completely dissolved, it was cooled to room temperature, and then 0.3512g p-aminobenzoic acid was added, React at 195°C for 12 hours; after the reaction, slowly pour the solution cooled to room temperature into hot water, the product precipitates, wash with water to neutrality and then vacuum dry to obtain 0.6952g of copolymer (II)-1, the yield is about 70.90%. Wherein: during the reaction process, the molar ratio of the amino-containing monomer to the polymer A is controlled at 1:1.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com