Ash residue ceramic vacuum-filter system

A ceramic vacuum and filter system technology, applied in the direction of filtration separation, gravity filter, fixed filter element filter, etc., can solve the problems of high operating cost, complicated equipment, high energy consumption, etc., and achieve low operating cost, simple equipment, and high energy efficiency. The effect of low consumption

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

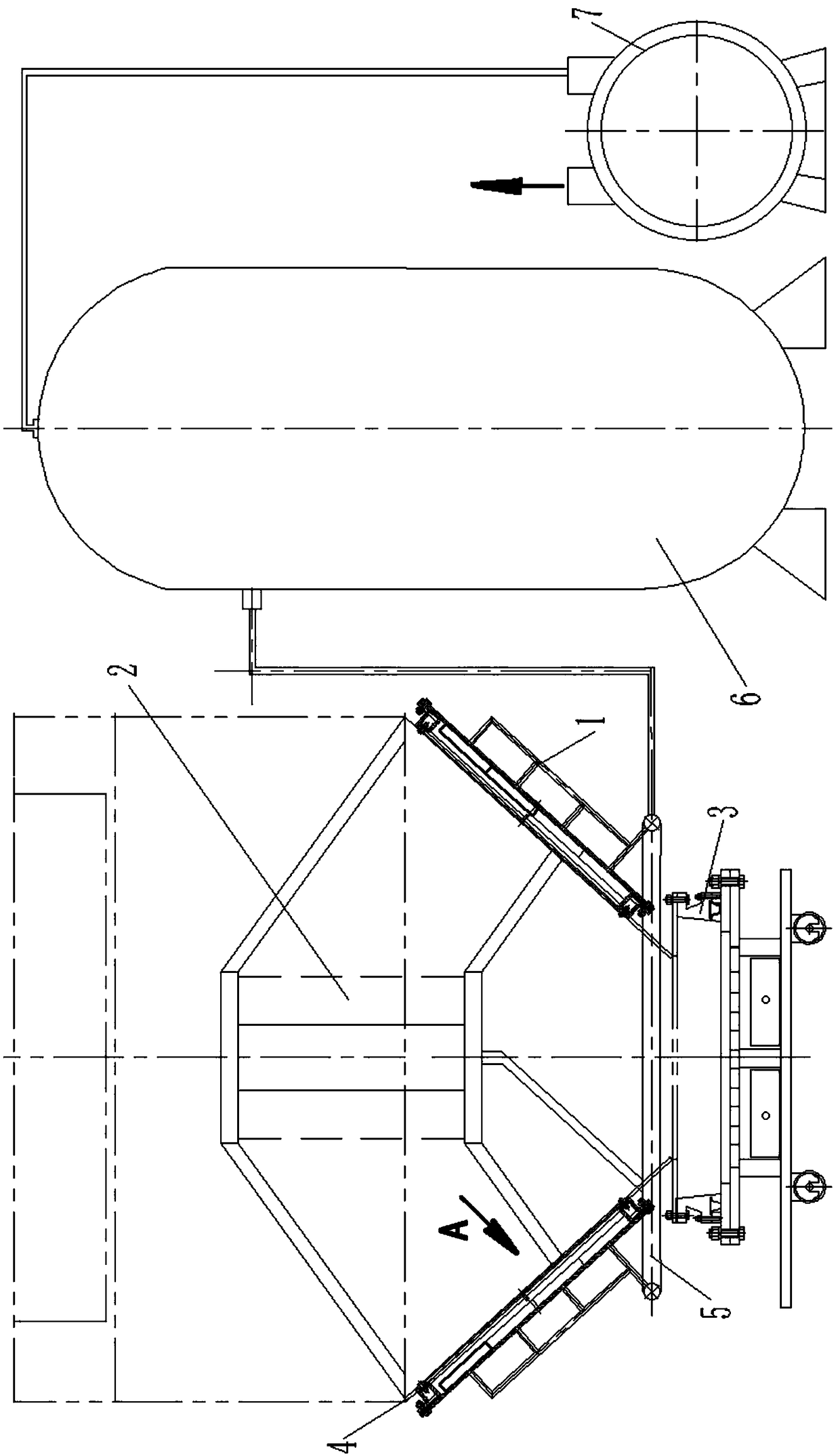

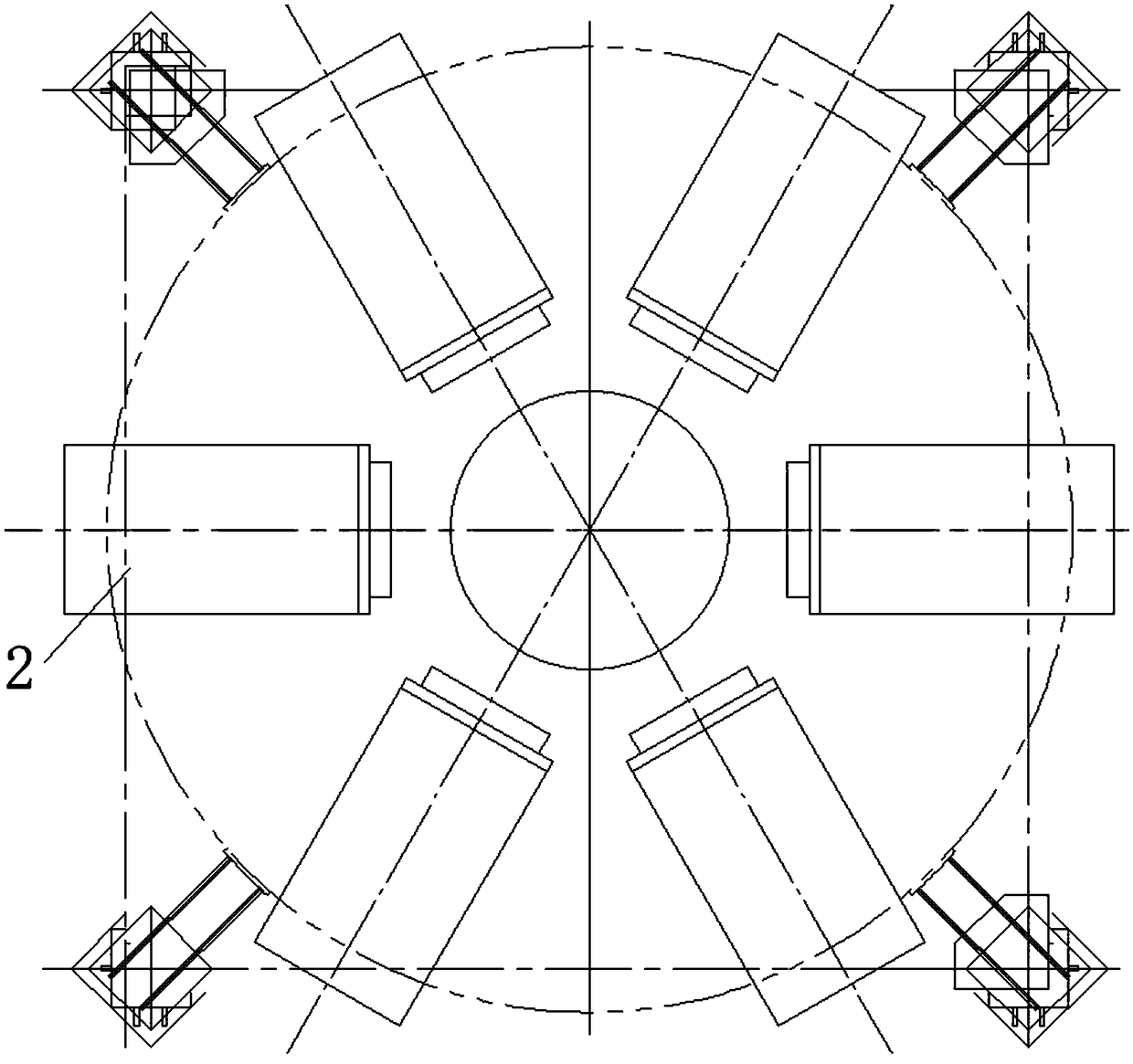

[0024] exist Figure 1 to Figure 5 Among them, the ash ceramic vacuum filtration system of the present invention includes several side filters 1 installed on the side wall of the ash bin body 4 and connected with the main water pipeline 5 located at the lower part of the ash bin body, installed in the ash bin body The central filter 2 connected to the main water pipeline 5 located at the bottom of the ash silo body, the main body 3 of the inflatable sealing ring installed on the bottom of the ash silo body, and the water storage tank 6 connected to the main water pipeline , the vacuum pump 7 that is connected with water storage tank.

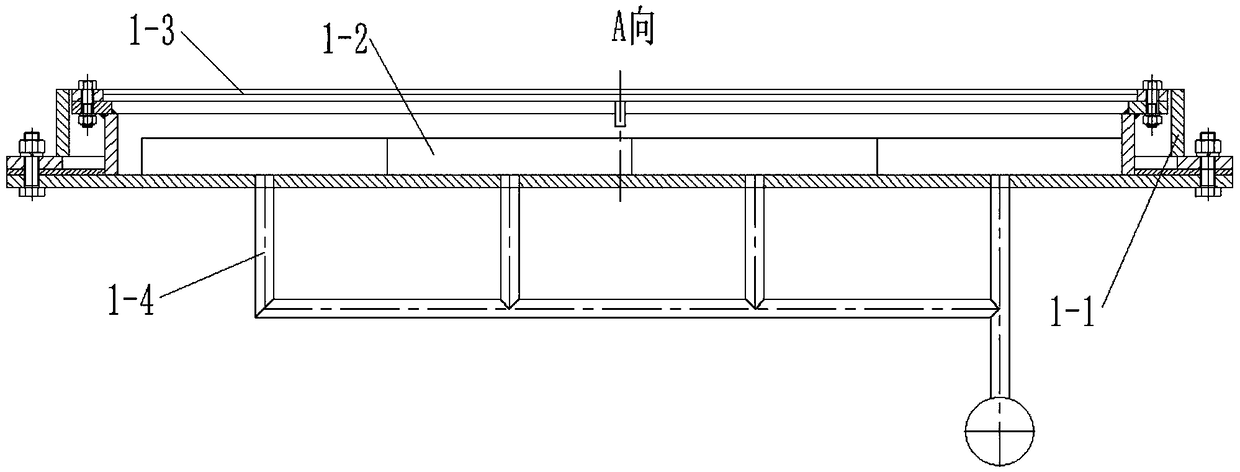

[0025] The ash and slag ceramic vacuum filtration system of the present invention, the side filter 1 includes a groove-shaped water analysis support 1-1, and several vacuum-type ceramic filters installed on the upper bottom surface of the middle groove of the water analysis support 1-2, the filter screen 1-3 installed on the groove top of the g...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com