Car chain winding, rolling-up and packaging device

A technology for chains and car chains, applied in the field of car chain winding, winding and packaging devices, can solve the problems of slow packaging and winding process, increase production costs, etc., and achieve the effects of improving winding and packaging efficiency, improving efficiency, and saving manpower

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

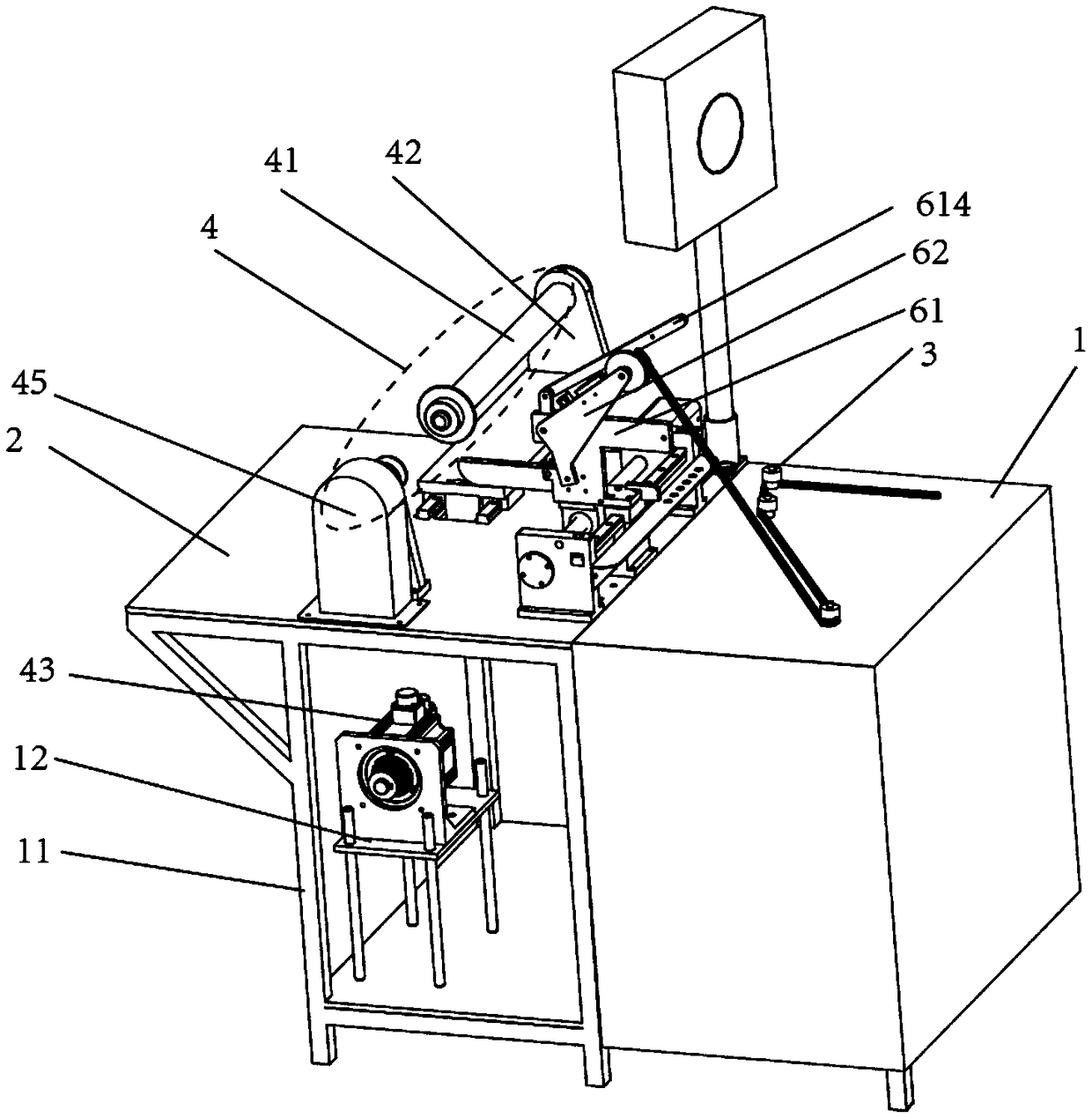

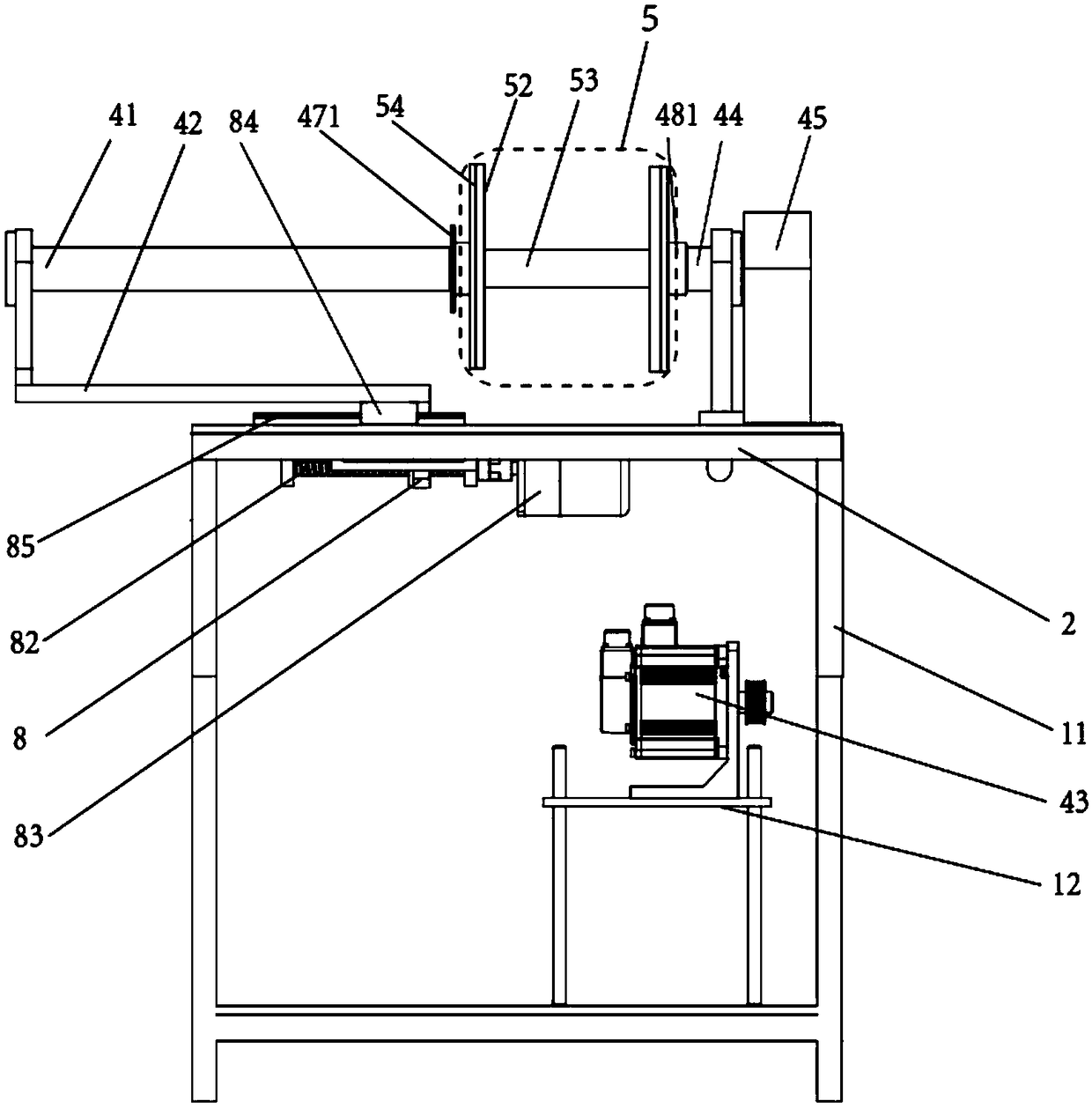

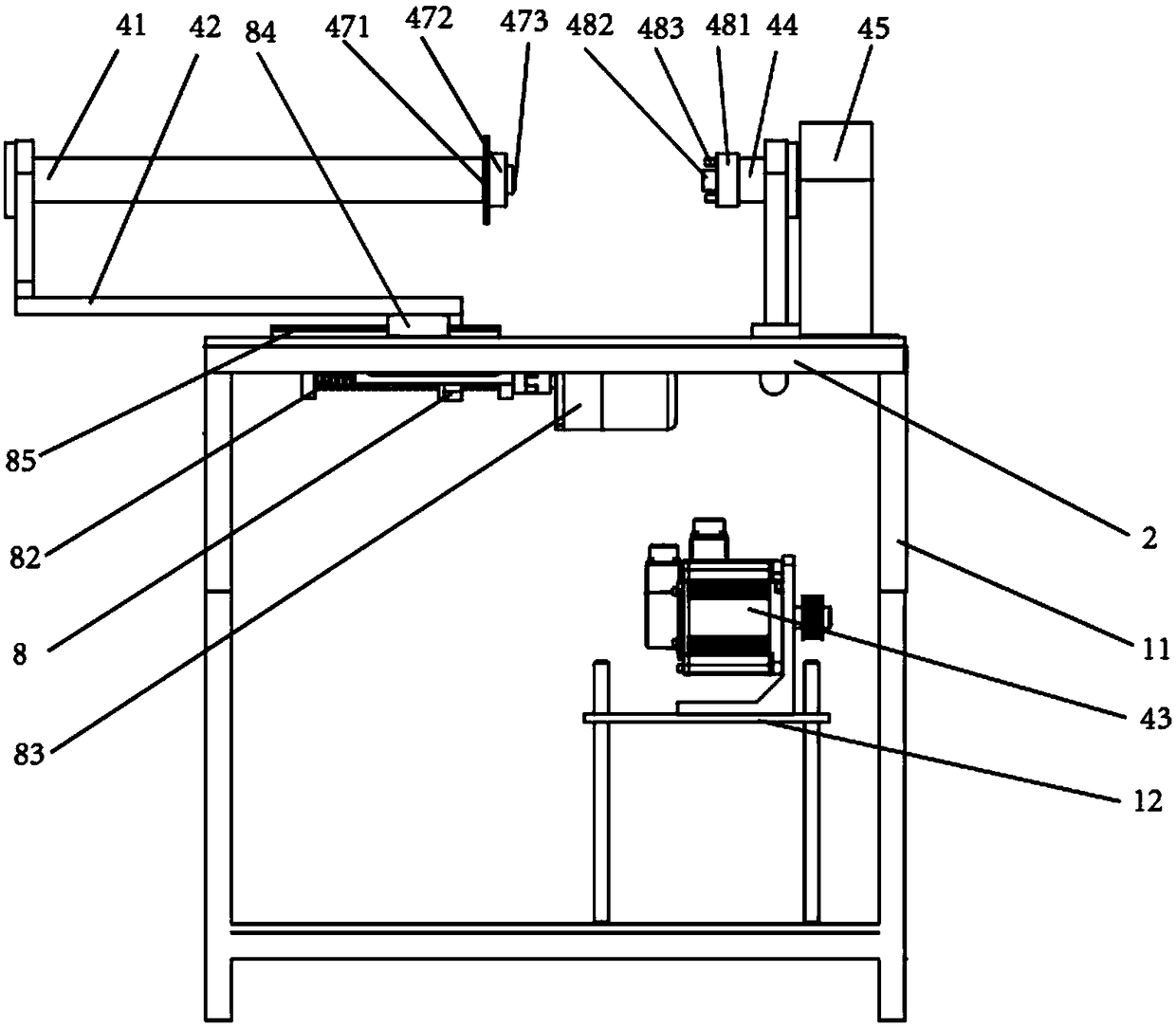

[0066] figure 1 Schematic diagram of the structure of the vehicle chain winding and packaging device provided by the embodiment of the present invention; figure 2 The front view of the chain winding mechanism provided by the embodiment of the present invention; image 3 The front view of the rolling chain mechanism provided by the embodiment of the present invention; Figure 4 Schematic diagram of the structure of the rolling chain mechanism provided by the embodiment of the present invention; Figure 5 It is the front view of the film of the embodiment of the present invention; Figure 6 Front view of the film and connecting roller assembly of the present invention; Figure 7 A side view of the film invented for; Figure 8 A cross-sectional view of the assembly of the fixed shaft and the second fixed block of the chain bearing mechanism provided for the embodiment of the present invention; Figure 9 A cross-sectional view of the assembly of the film-coated reel and the ...

Embodiment 2

[0081] In some other embodiments of the present invention, it is also possible to freely and flexibly configure the vehicle chain winding and packaging device, so as to give full play to the technical advantages of the present invention. This is illustrated below with an example.

[0082] Figure 15 Another structural schematic diagram of the rolling chain mechanism provided by the embodiment of the present invention; Figure 16 Another structural sectional view of the assembly of the fixed shaft and the second fixed block of the chain bearing mechanism provided for the embodiment of the present invention; Figure 15-16 As shown, the vehicle chain winding and packaging device provided in this embodiment is a further improvement on Embodiment 1: it can be considered that the first fixing block 47 of the chain carrying mechanism includes a blocking piece 471, a first pressing block 472, a second A supporting column 473, the first pressing block 472 and the first supporting col...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com