Bonding type coach roof skin

A skin and top cover technology, which is applied to vehicle components, upper structures, and upper structure sub-assemblies, can solve problems such as reducing aesthetics, cumbersome manufacturing processes, and tearing skins, so as to improve product durability and reliability. Good performance, operability and safety, easy production and post-maintenance

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0017] The present invention is described in detail below in conjunction with accompanying drawing and specific embodiment:

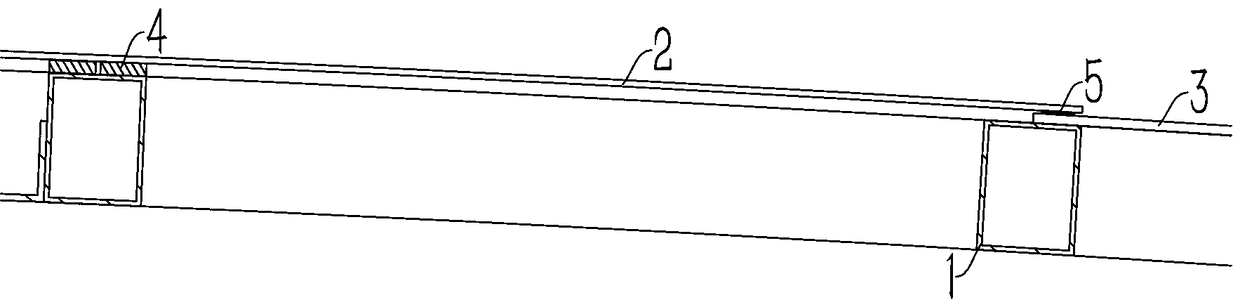

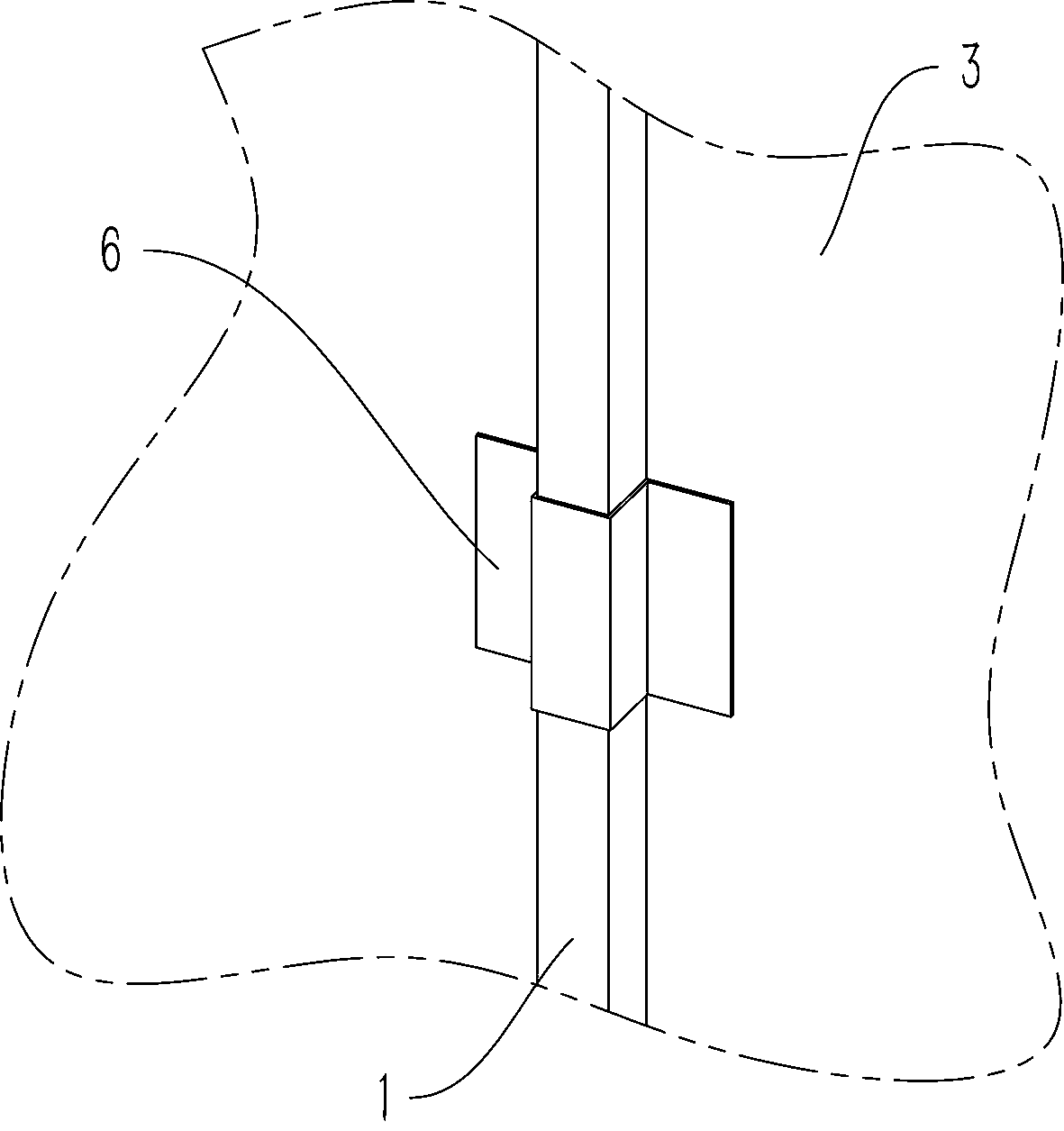

[0018] Such as figure 1 and figure 2 As shown, the roof frame 1 is fixed with a side roof skin 3 and a middle roof skin 2, the upper part of the side roof skin 3 is fixed on the top surface of the roof frame 1, and the edge of the middle roof skin 2 is fixed on the side On the edge of the top skin 3 upper part. A thick rubber pad 4 is arranged between the middle roof skin 2 and the roof frame 1, a thin rubber pad 5 is arranged between the edge of the middle roof skin 2 and the upper edge of the side roof skin 3, the thick rubber pad 4 and the thin rubber pad The rubber pads 5 are evenly distributed at fixed intervals. The middle roof skin 2 is a flat structure, and the upper part of the side roof skin 3 is a flat structure.

[0019] The thick rubber pad 4 is 4mm thick, and the thin rubber pad 5 is 1mm thick.

[0020] The side top skin 3 is made of...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com