Personalized articular bone cement spacer mold and preparation method

A spacer and articular bone technology, applied in the field of medical devices, can solve the problems of time-consuming spacer bone cement model, increased surgical risk, and reduced surgical effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

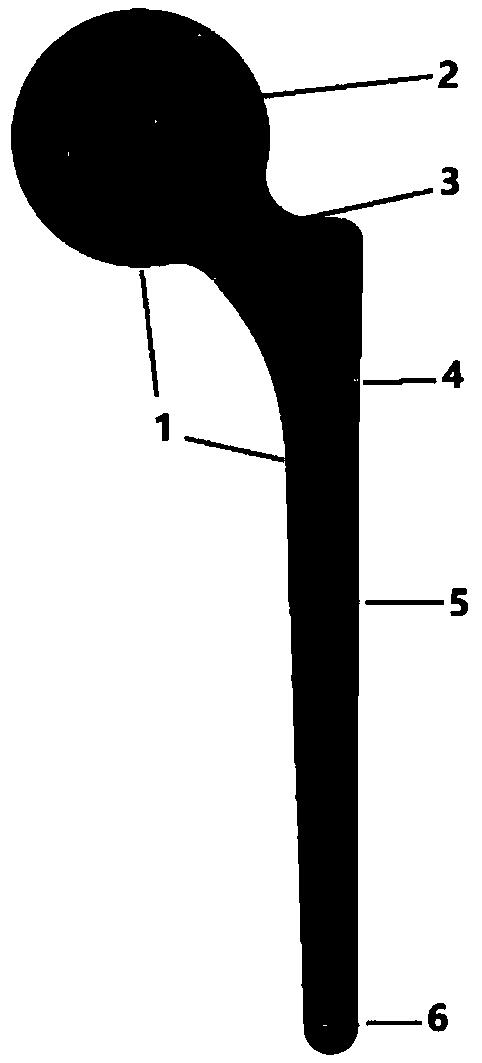

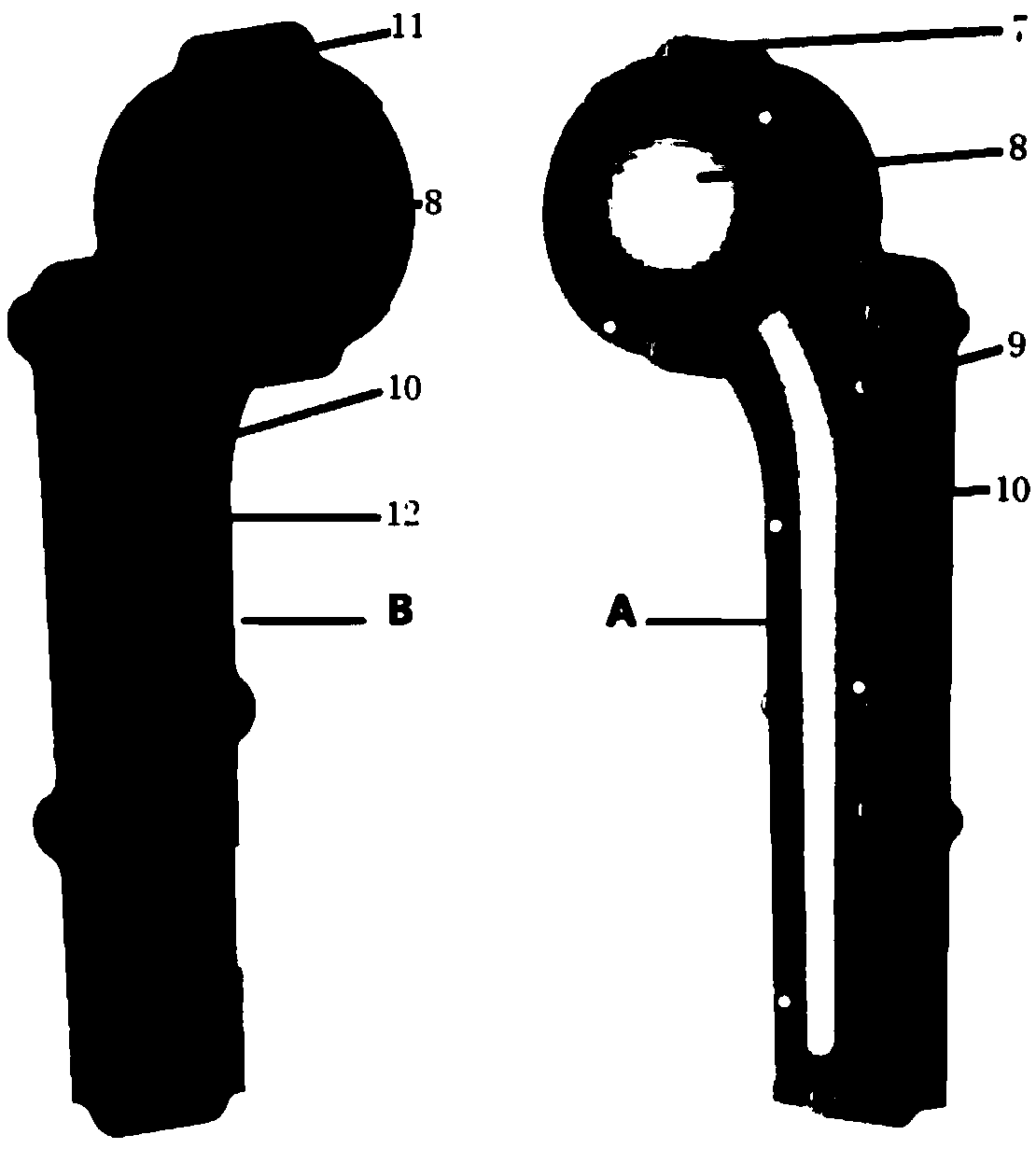

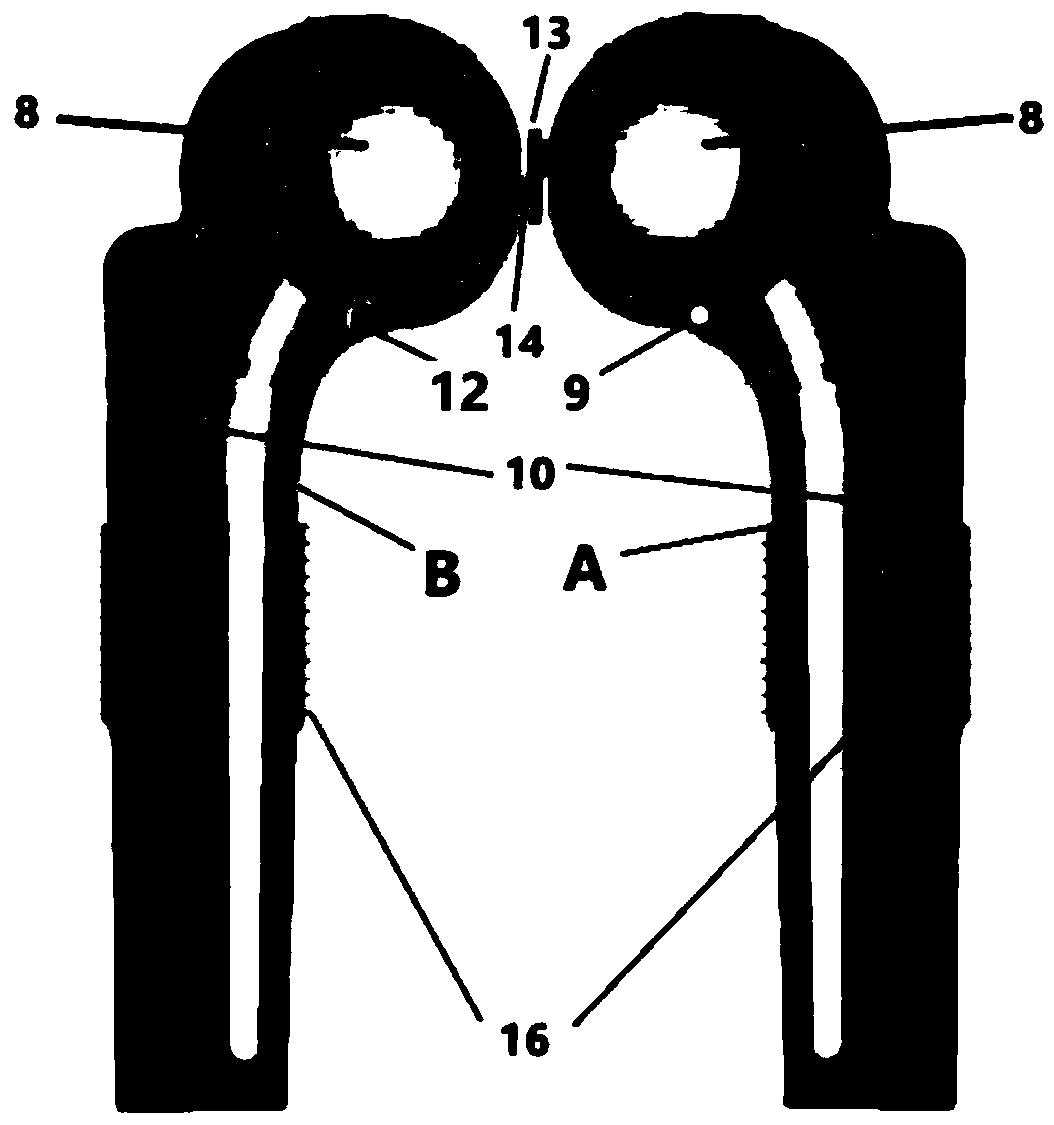

[0039] A personalized joint bone cement spacer mold, which is provided with a lower mold A and an upper mold B, and the lower mold A and upper mold B are respectively matched with the bone cement spacer groove 8 and the bone cement spacer 1 provided with the bone cement spacer The injection port 10 is matched with the circular protrusion 9 or the circular groove 12 and the fastening screw hole 7 or the fastening screw hole 11, and the bottom mold A and the upper mold B are connected and fixed with screws.

[0040] The above-mentioned lower mold A and upper mold B are provided with buckle rings 18 corresponding to the molds of the upper segment 4 of the bone cement spacer handle.

Embodiment 2

[0042] A personalized joint bone cement spacer mold, which is provided with a lower mold A and an upper mold B, and the lower mold A and upper mold B are respectively matched with the bone cement spacer groove 8 and the bone cement spacer 1 provided with the bone cement spacer The injection port 10 is matched with the circular protrusion 9 or the circular groove 12 and the fastening threaded hole 7 or the fastening screw hole 11, and the bottom mold A and the upper mold B are connected and fixed with bolts.

[0043] The lower mold A and the upper mold B mentioned above, the bone cement spacer heads 2 of the lower mold A and the upper mold B are matched with the upper and lower mold connecting ears 14, and the movable shaft 13 is used for positioning and connection.

[0044] The above-mentioned lower mold A and upper mold B are provided with buckle rings 18 corresponding to the molds of the upper segment 4 of the bone cement spacer handle.

Embodiment 3

[0046] A personalized joint bone cement spacer mold, which is provided with a lower mold A and an upper mold B, and the lower mold A and upper mold B are respectively matched with the bone cement spacer groove 8 and the bone cement spacer 1 provided with the bone cement spacer The injection port 10, the handles of the lower mold A and the upper mold B are respectively matched with the thread 16, and the nuts 17 are arranged, and the upper and lower mold connecting ears 14 are matched with the tails of the bone cement spacers of the lower mold A and the upper mold B, and the movable shaft is used. 13 positioning connection.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com