Delivery type spacer

A spacer and drop-in technology, which is applied in the field of spacers, can solve the problems of wasting spacers, spacers stuck in the blast hole, and failing to reach the predetermined position.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

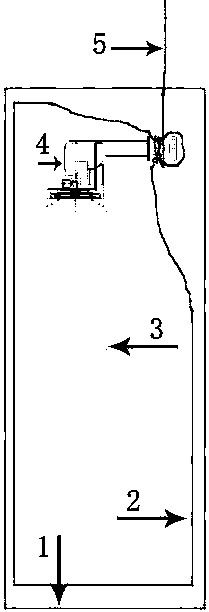

[0008] The present invention will be further described below in conjunction with accompanying drawing:

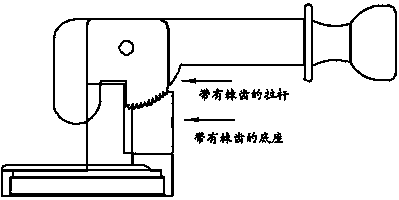

[0009] Such as figure 1 , figure 2 , as shown, the present invention relates to a delivery spacer spacer, 1 woven bag, 2 composite bags, 3 gas storage tanks, 4 deflation switches and 5 switch ropes, characterized in that the delivery type spacer is equipped with Switch cord 5 is on the air release switch 4, and the air release switch 4 is pressed on the air storage tank 3, and the air storage tank 3 is placed in the composite bag 2, and the composite bag 2 is contained in the woven bag 1 inside. When using, pull the switch rope 5, lower the spacer to the predetermined position, then step on the switch rope 5 with your feet, then pull the switch rope 5 with your hands to lift the spacer about two meters, and then send off the switch rope 5 by hand , at this time, the spacer generates a downward movement force, and since one end of the switch rope 5 is stepped on by the fo...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com