Friction type retarder

A retarder and friction-type technology, which is applied to transmission parts, belts/chains/gears, mechanical equipment, etc., can solve the problems of affecting the use effect, high cost, and inconvenient promotion and application of retarders.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

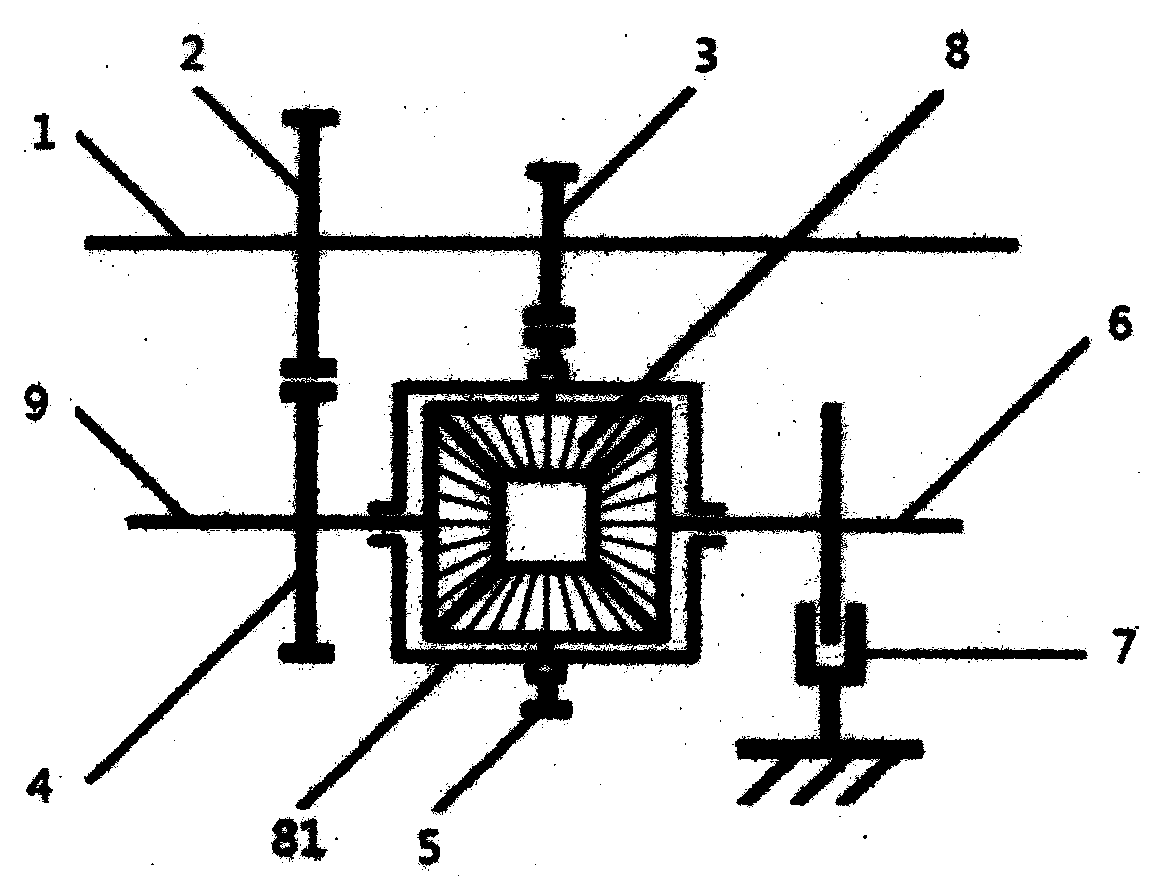

[0019] Example 1, see figure 1 , a friction retarder, including a main shaft, a planetary gear train with three connecting ends and a friction brake pair, gears (2), (3) are fixedly installed on the main shaft (1), gears (2), (3 ) meshes with the fixedly installed gears (4) and (5) on any two connecting ends of the planetary gear train, and through the setting of the transmission ratio between the gear pairs, the third connecting end of the planetary gear train is relative to the main shaft (1 ) to do deceleration rotation, and a friction pair (7) is installed on the third connection end.

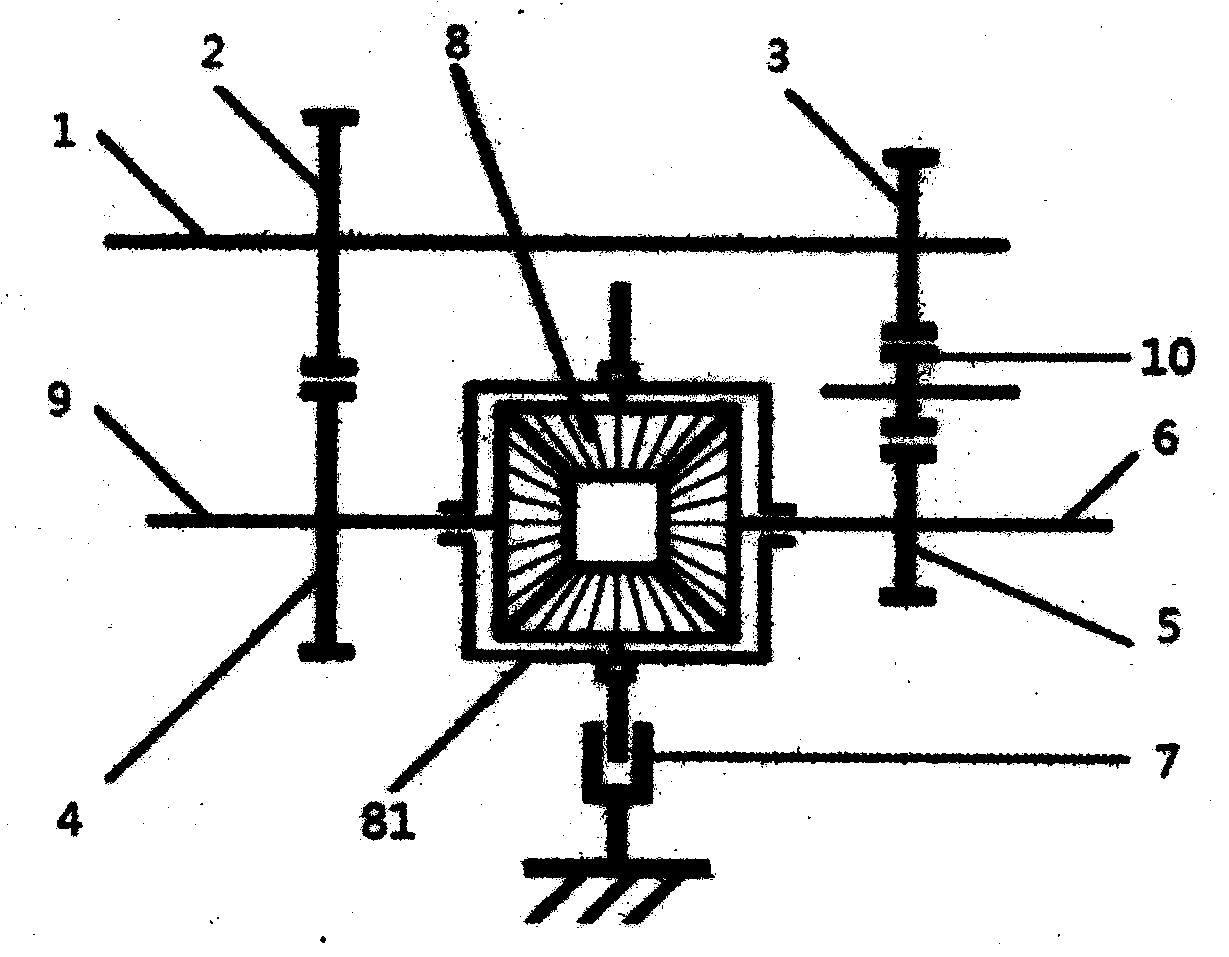

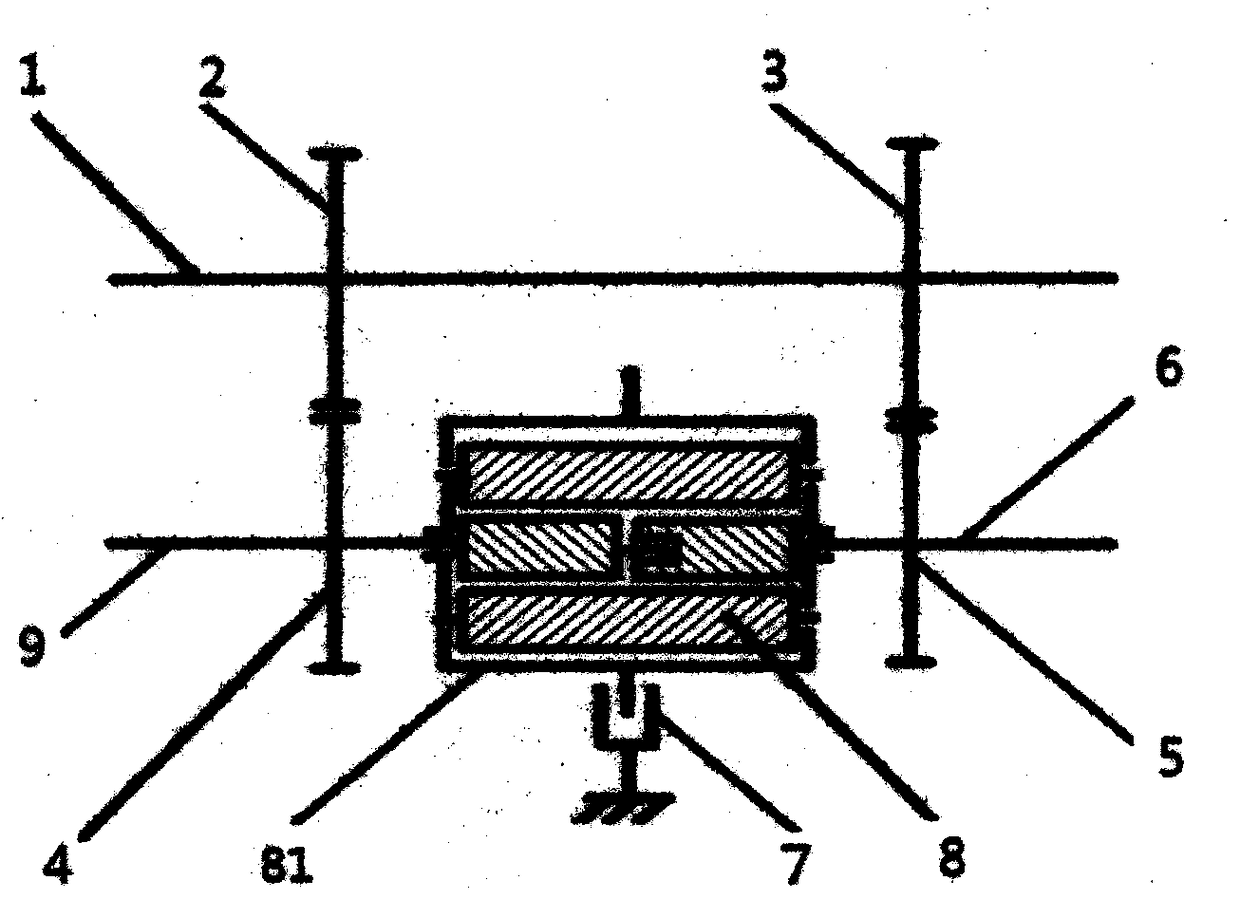

[0020] figure 2 , image 3 , Figure 4 Both are figure 1 deformation structure, where figure 2 In the structure, need to add an idler wheel (10) between gear (3) and gear (5).

Embodiment 2

[0021] Example 2, see Figure 5 , a friction retarder, including a main shaft, a planetary gear train with three connecting ends and a friction brake pair, a gear (2) is fixedly installed on the main shaft (1), and any one of the gear (2) and the planetary gear train The gear (5) fixedly installed on the connection end meshes, the gear (5) meshes with the gear (3), the gear (3) and the gear (11) are fixedly installed on the shaft (12), the gear (11) and the planetary gear train The gear (4) fixedly installed on the second connection end meshes, and the third connection end of the planetary gear train is decelerated relative to the main shaft (1) through the setting of the transmission ratio between the gear pairs, and on the third connection end A friction pair (7) is installed.

[0022] Image 6 , Figure 7 Yes Figure 5 The deformed structure, this structure is also suitable for such as image 3 , Figure 4 planetary gear train shown, but in image 3 In the structure ...

Embodiment 3

[0023] Embodiment three, see Figure 8 , in this embodiment, the axis (13) is used as the retarder control target axis, and the retarder control target axis (13) is connected with the main shaft (1) in the retarder through the gear (14), and the gear (14) Can be connected on any gear on the main shaft (1), and can install clutch (15) additionally on gear (14), on the gear that clutch also can be installed and the meshing of connecting gear (14). When the clutch is disengaged, the cooperating gear can rotate freely around the shaft; when the clutch is engaged, the cooperating gear and the shaft rotate synchronously.

[0024] The friction pair is one or more groups.

[0025] Described gear transmission also can replace with sprocket wheel and chain transmission.

[0026] The friction pair is caliper-brake disc or friction disc-brake disc or brake shoe-brake drum or friction cone-cone ring brake drum.

[0027] The retarders can be used alone or in combination. When used in com...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com