Steel structure positioning and conveying construction frame

A construction frame and steel structure technology, which is applied in the direction of building construction, construction, and building material processing, can solve problems such as adjustment, angle adjustment, and potential safety hazards in I-beam transmission, and achieve the effect of increasing transmission accuracy

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0024] In order to make the technical means, creative features, goals and effects achieved by the present invention easy to understand, the present invention will be further elaborated below in conjunction with specific illustrations. It should be noted that, in the case of no conflict, the embodiments in the present application and the features in the embodiments can be combined with each other.

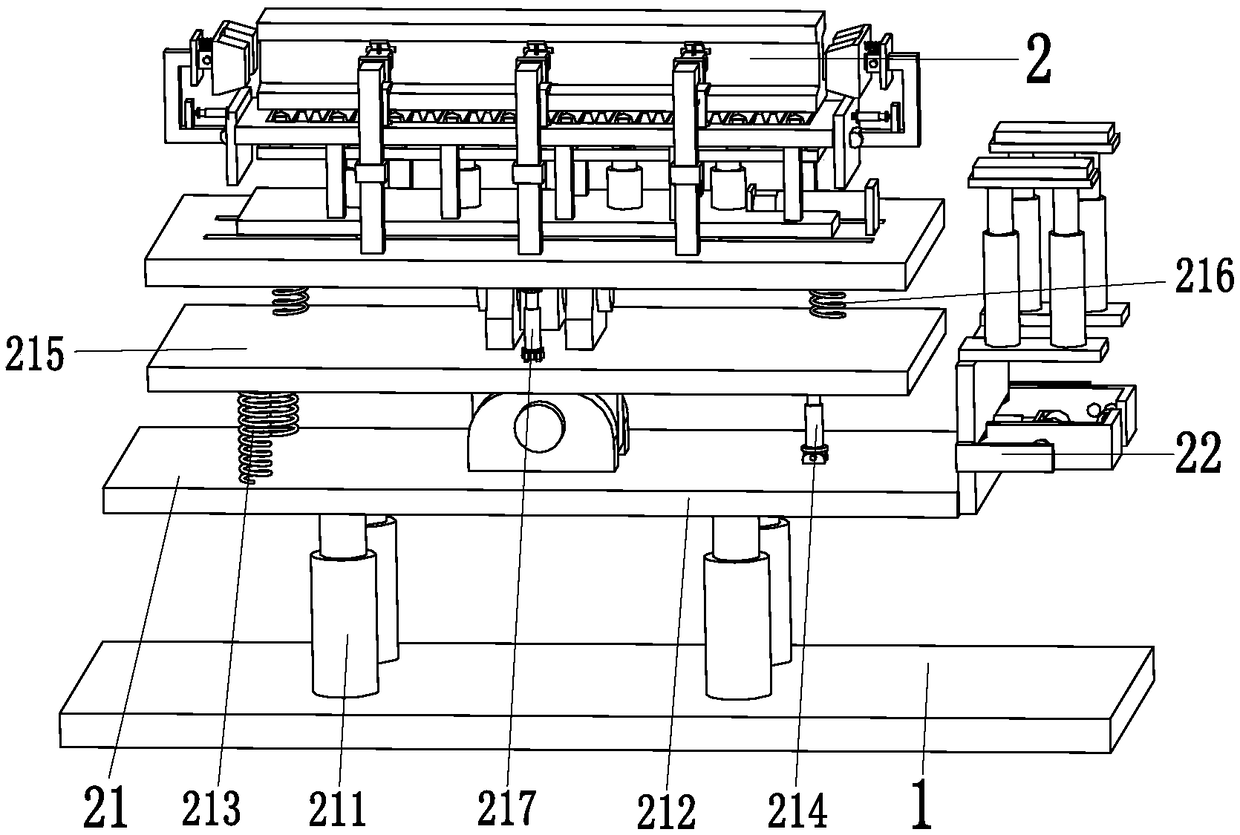

[0025] Such as Figure 1 to Figure 5 Shown, a kind of steel structure positioning conveys construction frame, comprises supporting base plate 1 and lifting device 2, and lifting device 2 is installed on the top of described supporting base plate 1.

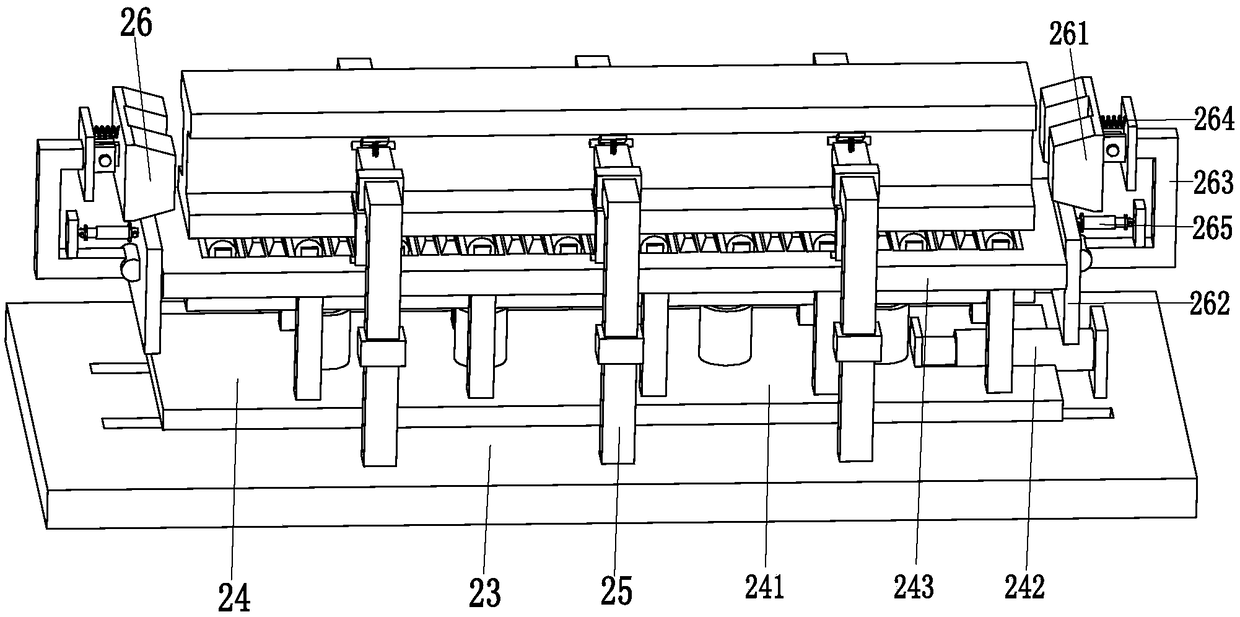

[0026] The lifting device 2 includes a lifting adjustment mechanism 21, a limit mechanism 22, a fixed base plate 23, a locking mechanism 24, a side fixed branch chain 25 and a locking mechanism 26, and the lifting adjustment mechanism 21 is installed on the top of the supporting base plate 1. A fixed bottom plate 23 is installed on the...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com