Method for manufacturing a patterned floor covering, and patterned floor covering

A patterned, ground-based technology, applied to home appliances, other home appliances, household components, etc., can solve problems such as floor coverings that have not yet been obtained

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

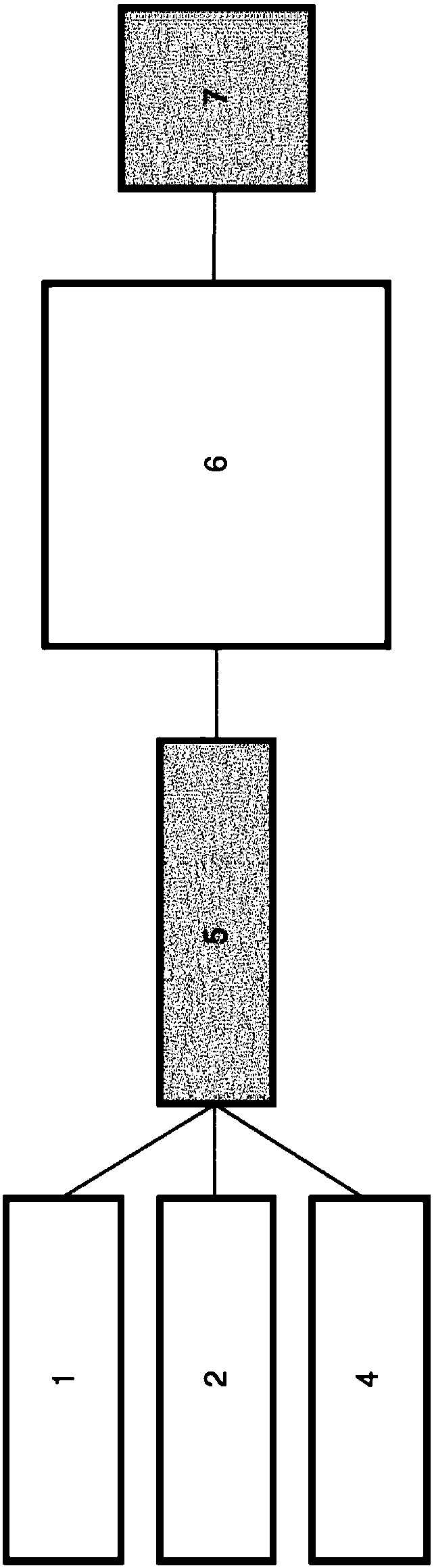

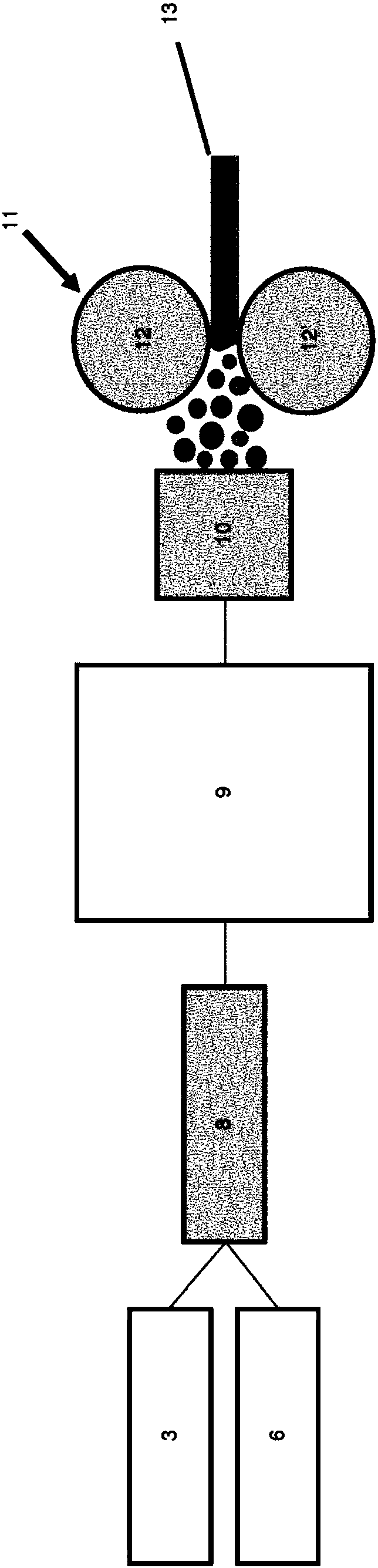

[0044] figure 1 The first part of the sequence of the method for manufacturing a patterned floor covering is schematically shown. A first element 1 and a second element 2 are provided. Also provided in the figure 2 The third element used in the second part of the method described in 3. Also from figure 1 As can be seen in the figure, a further element 4 is provided in the illustrated embodiment. The first, second, third and further elements 1-4 are mixable materials. The first element 1 has a first basic color and the second element 2 has a second basic color. The third element 3 has a third basic color identical to the first basic color. According to the invention, it is preferred that the third element 3 has the same basic color as the first element 1 as well as the rest of its composition. Further elements 4 have further basic colors. First, second and additional base colors vary. The exemplary embodiment shown provides that the second basic color is darker than t...

PUM

| Property | Measurement | Unit |

|---|---|---|

| thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com