Power supply wiring column structure and use method thereof

A technology of power supply wiring and column structure, applied in the direction of conductive connection, circuit, connection, etc., can solve the problem of relative rotation, and achieve the effect of avoiding relative rotation, high safety, and enhanced prevention.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

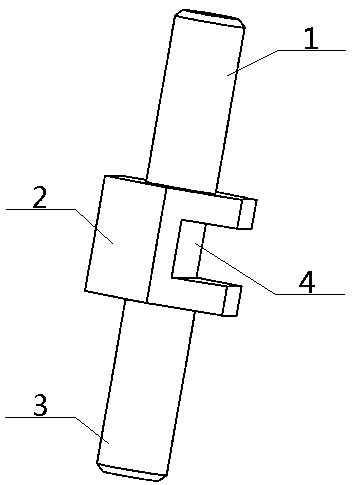

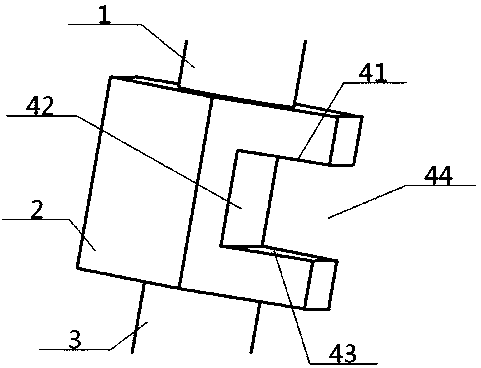

[0039] see Figure 1 to Figure 3 , a power terminal structure, including an upper thin column 1, a middle extension seat 2 and a lower thin column 3 (the upper thin column 1 and the lower thin column 3 are provided with threads), the bottom end of the upper thin column 1 and the middle The top surface of the extension seat 2 is connected, and the bottom surface of the middle extension seat 2 is connected with the top surface of the lower thin column 3; the side wall of the middle extension seat 2 is provided with a concave injection groove 4, and the injection groove 4 is a one-way The opening structure comprises an upper groove edge 41, a left groove bottom 42 and a lower groove edge 43, the inner end of the upper groove edge 41 is connected with the inner end of the lower groove edge 43 through the left groove bottom 42, and the outer end of the lower groove edge 43 is connected with the lower groove edge 43. A groove opening 44 is sandwiched between the outer ends of the up...

Embodiment 2

[0042] Basic content is the same as embodiment 1, the difference is:

[0043] The cross section of the upper thin column 1 and the lower thin column 3 is circular, oval or polygonal, the cross section of the middle extension seat 2 is circular, oval or polygonal, and the shape of the injection molding groove 4 is groove or wedge groove.

Embodiment 3

[0045] Basic content is the same as embodiment 2, the difference is:

[0046] The cross-section of the middle extension seat 2 is a regular hexagon; the shape of the injection molding groove 4 is an I-shaped groove, the left groove bottom 42 is rectangular, and the upper groove edge 41 and the lower groove edge 43 are both inner width Outer narrow isosceles trapezoid, the broad side on the upper groove edge 41, the lower groove edge 43 is vertically connected with the left groove bottom 42.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com