Seed drying box with screening function

A technology of drying box and seeds, applied in drying, drying machine, sieve and other directions, can solve the problems such as failure to achieve drying, inability to remove impurities such as seed pods and gravel beforehand, and seeds becoming wet, etc. achieve the effect of reducing dust

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

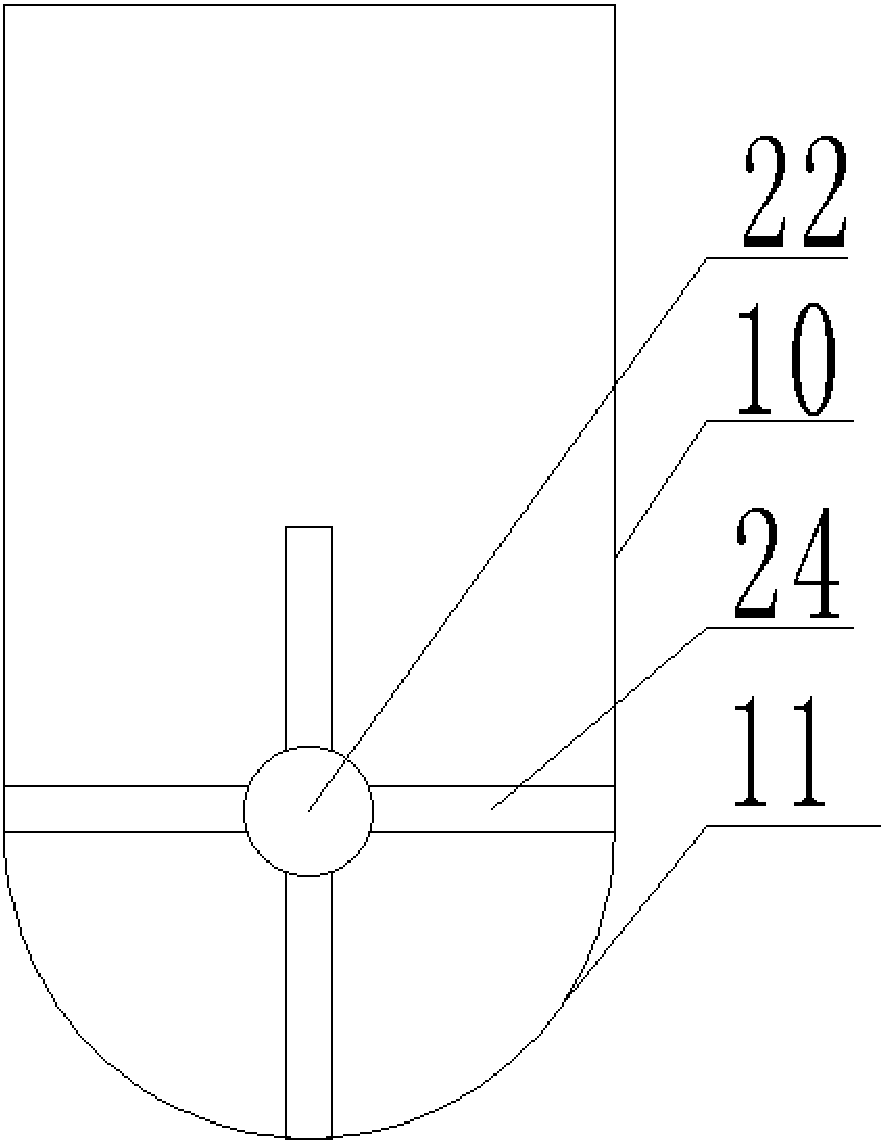

[0026] Such as Figure 1-3 As shown, a seed drying box with screening function includes a box body 1, the top of the box body 1 is provided with a feed port 2, and the box body 1 is sequentially provided with a first filter assembly and a drying assembly from top to bottom. And the second filter assembly; The first filter assembly includes filter screen 5, vibrator 23 and vibration power supply 6, the mesh of filter screen 5 is larger than the particle diameter of seed, and filter screen 5 is arranged on the below of feed inlet 2, and vibration power supply 6 And the vibrator 23 is arranged on the bottom of the filter screen 5, and the vibration power supply 6 is electrically connected to the vibrator 23; the side walls at both ends of the box body 1 on the filter screen 5 are respectively provided with operation windows 4;

[0027] The drying assembly includes a drying bin, a heater 12, a motor 20, a rotating shaft 22, a bearing seat 8 and fan blades 15, and the drying bin is...

Embodiment 2

[0032] Such as Figure 1-3 As shown, the present embodiment is further optimized on the basis of Embodiment 1. On the top wall of the casing 1 at the top of the filter screen 5, several negative pressure devices 3 for dust collection are provided; the negative pressure devices 3 include negative pressure devices. Pressure cover and negative pressure tube, one end of the negative pressure tube is connected with the negative pressure cover, the other end of the negative pressure tube is connected with the side wall of the box body 1, and the negative pressure tube is arranged on the side wall of the box body 1 to facilitate connection with the box body 1 The external negative pressure generating device is connected.

Embodiment 3

[0034] Such as Figure 1-3 As shown, this embodiment is further optimized on the basis of Embodiment 1. The push plate 14 is composed of a main board 141 and a sub-board 142. The two sides of the main board 141 are respectively provided with a sub-board 142. The main board 141 is arranged obliquely and parallel to the filter plate 19. , and the cross-section of the push plate 14 is triangular, and the upper surface near the high end of the main board 141 is provided with a plurality of through-through second via holes 143. When the electric telescopic rod 18 drives the push plate 14 from long to short, the push plate 14 Impurities are removed. When the electric telescopic rod 18 drives the push plate 14 from short to long, there may be some impurities between the filter plate 19 and the support plate 16. Because the main board 141 of the push plate 14 is inclined, the impurities will flow from the main board. The second via hole 143 of 141 passes through, so that it can be rem...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com