Electric water pump and water gun structure with water flow buffer chamber

An electric water pump and buffer chamber technology, which is applied to the components, pumps, piston pumps, etc. of the pumping device for elastic fluid, can solve the problem of limiting the application range of electric water pumps, large volume, cost of electric water pumps, increase in volume and mass, etc. question

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0022] The technical solutions of the present invention will be described below in conjunction with the accompanying drawings and embodiments.

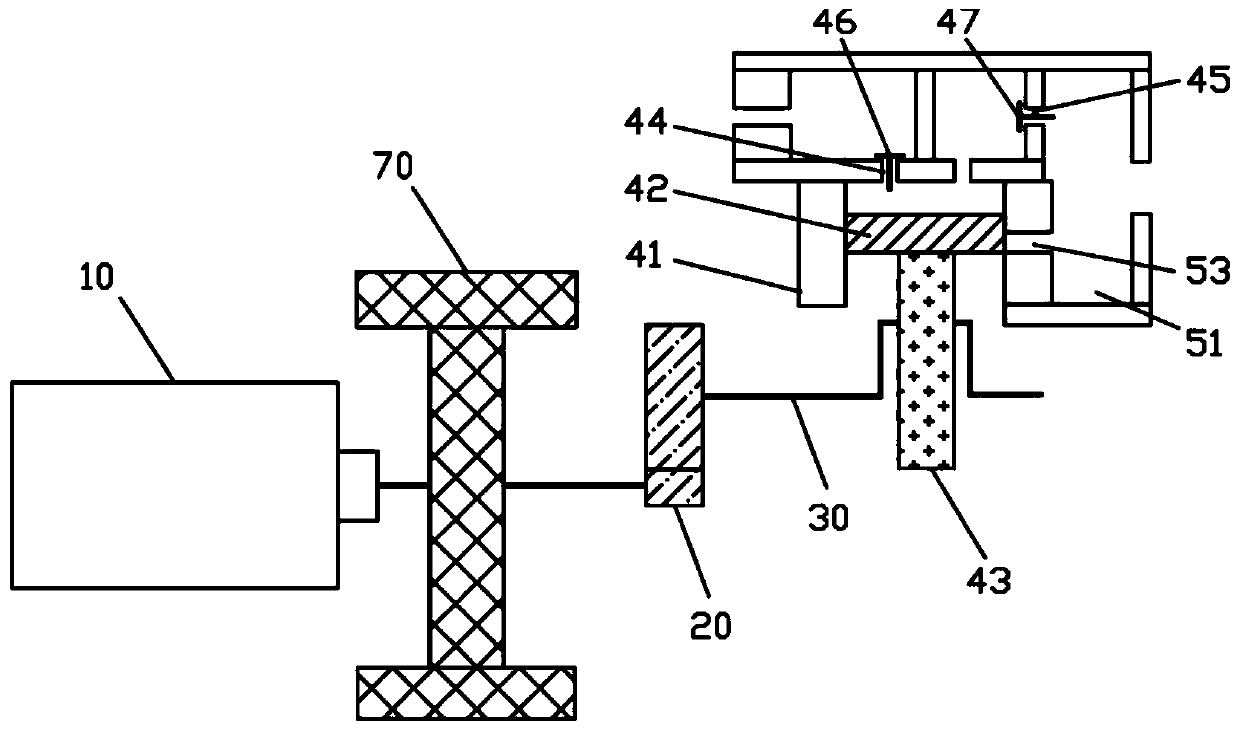

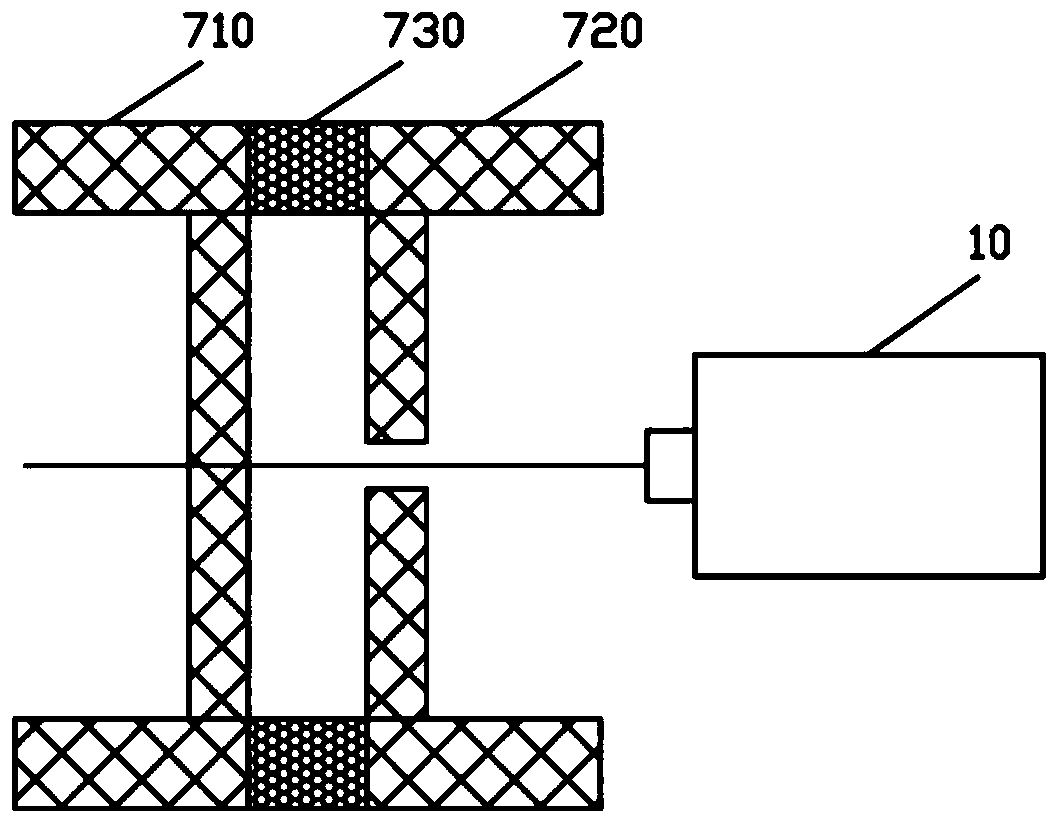

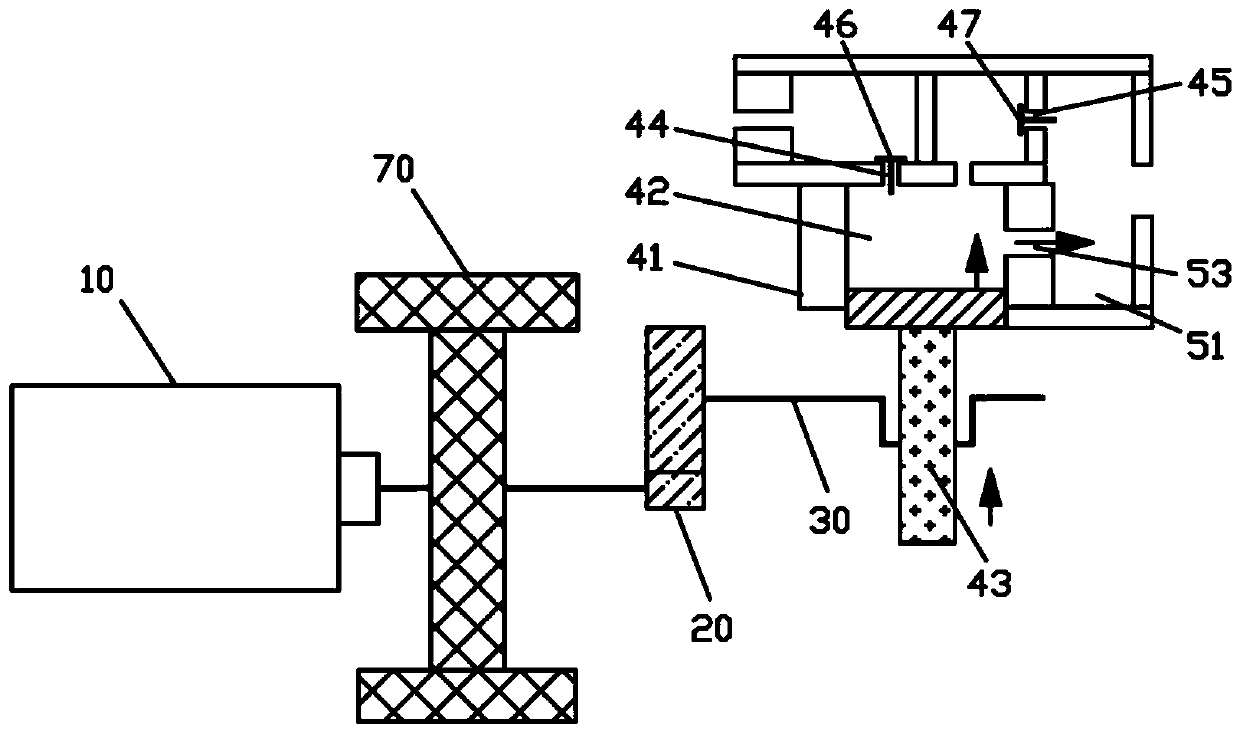

[0023] like figure 1 As shown, an electric water pump with a water flow buffer chamber according to the present invention includes a motor 10, a gear set 20, a transmission mechanism 30, a piston mechanism and a water flow buffer chamber 51, and the output shaft of the motor 10 is connected to the transmission mechanism through a gear set 20 30. The transmission mechanism 30 is connected to the piston mechanism (in practical applications, the piston mechanism adopts a single piston structure), the piston mechanism includes a piston cylinder 41, and the piston cylinder 41 is provided with a piston body 42, and the piston body 42 is connected to the transmission mechanism through a piston rod 43 30. The transmission mechanism 30 drives the piston body 42 to move up and down through the piston rod 43. The piston cylinder 42 is provided w...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com