Automatic drawing-off auxiliary detection device for yarns

A technology of auxiliary detection and thread pressing device, which is applied in the field of yarn textile machinery, and can solve the problems that cannot meet the needs of automatic production and use

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

specific Embodiment approach 1

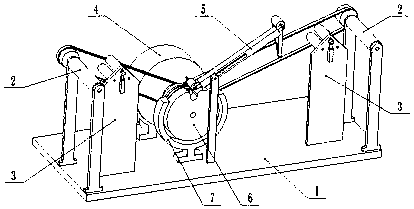

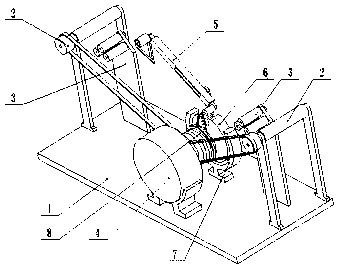

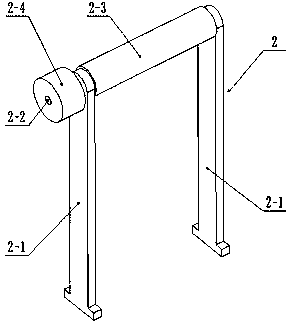

[0035] Such as Figure 1-17As shown, a yarn automatic extraction auxiliary detection device includes a frame 1, a thread feeding roller 2, a thread pressing device 3, a driving device 4, a tensioning device 5, a connecting rod sheave 6, a sheave frame 7 and Clutch device 8, each of the left and right ends of the frame 1 is fixedly connected with a transmission line rotating roller 2, and each of the left and right ends of the frame 1 is fixedly connected with a crimping device 3, and the two crimping devices 3 are located at two On the inner side of the line transmission roller 2, the tensioning device 5 is arranged at the middle end of the frame 1, the driving device 4 is fixedly connected to the frame 1, and the connecting rod sheave 6 is clearance-fitted on the sheave frame 7 Above, the sheave frame 7 is fixedly connected to the frame 1, the connecting rod sheave 6 is fixedly connected to one end of the clutch device 8, and the other end of the clutch device 8 is fixedly co...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com