Environment-friendly polybag heat packaging device and method

A heat-sealing and plastic bag technology, applied in the field of plastic bag heat-sealing, can solve the problems of heat-sealing knife temperature plastic bag film sticking, complex structure, too sudden contact between heat-sealing knife and backing plate, etc., and achieve the goal of improving packaging efficiency Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0031] Below in conjunction with accompanying drawing and specific embodiment the present invention is described in further detail:

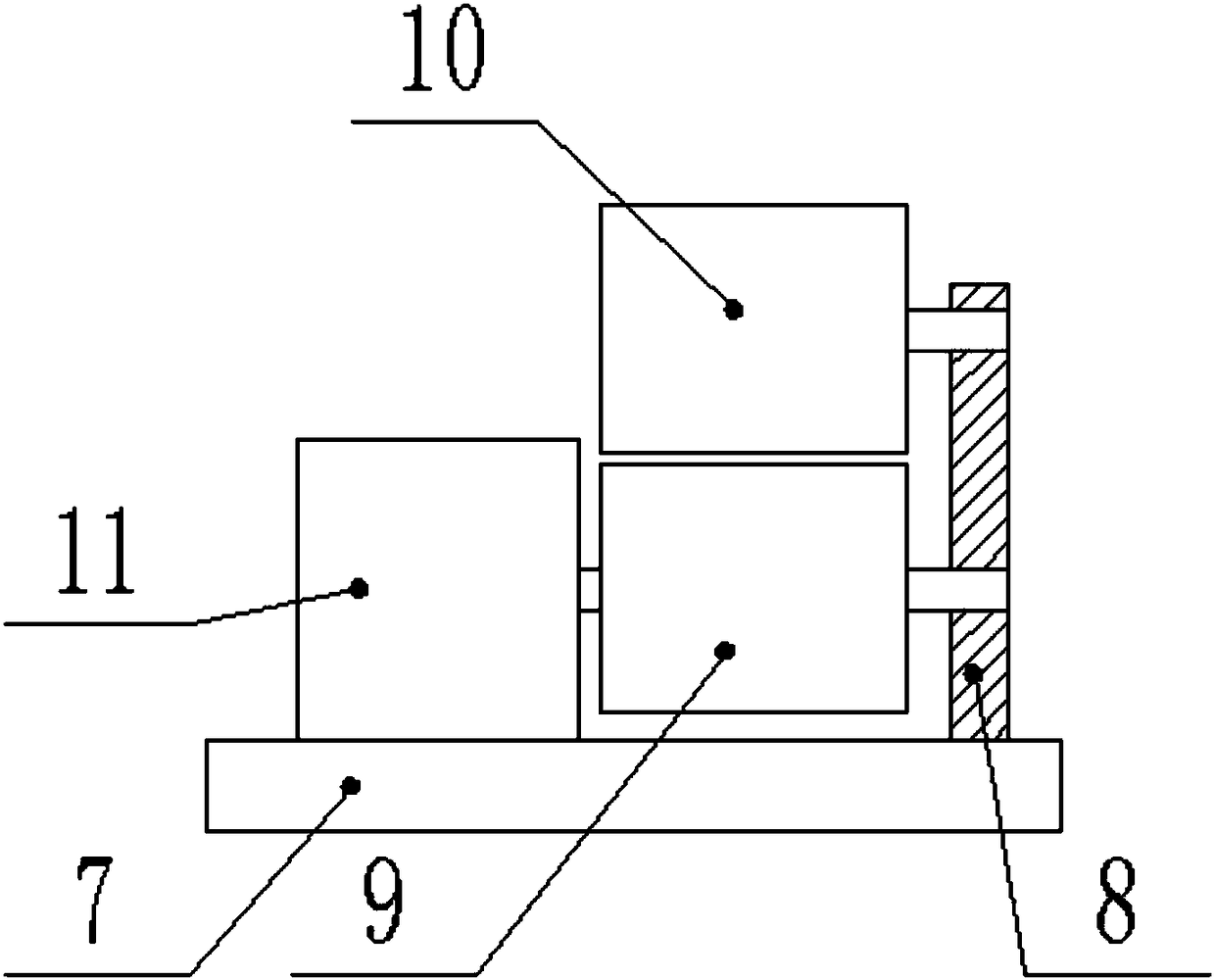

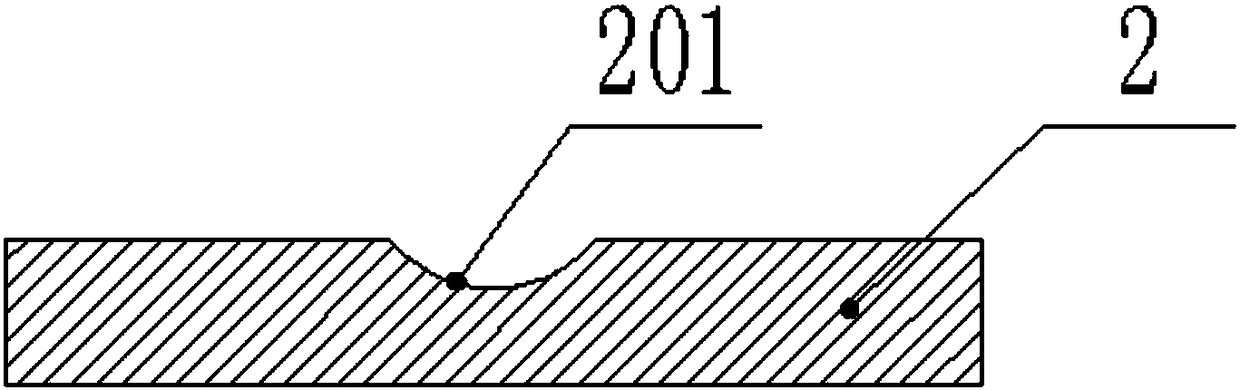

[0032] Such as figure 1 , figure 2 , image 3 , Figure 4 , Figure 5 As shown, a heat-sealing device and method for an environmentally friendly plastic bag includes a workbench 1, a plurality of through holes 101 are provided on the workbench 1, a backing plate 2 is embedded in the center of the workbench 1, and the backing plate 2. A pressure sensor 3 installed inside the workbench 1 is installed on the lower side. A cover 4 is fixed at the lower end of the workbench 1. The cover 4 is in the shape of an inverted platform. A suction fan 5 is fixed at the center of the lower end of the cover 4. Outriggers 6 are respectively fixed on both sides of the lower end of the cover body 4, a first side plate 7 is fixed on the side end of one leg 6, and a first bracket 8 and a first motor are respectively fixed on the upper end of the first side plat...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com