Compressor rotor large nut assembling support

A technology for compressor rotors and assembling brackets, which is applied to hand-held tools, manufacturing tools, etc., can solve problems such as exceeding the manual operation ability of workshop operators, inability to complete rotor assembly work, and difficulty in assembling large nuts. The effect of improving the technical level of tools and improving labor efficiency

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0032] The specific implementation of the compressor rotor big nut assembly bracket of the present invention will be described below with reference to the accompanying drawings.

[0033] Embodiment of assembly bracket of compressor rotor big nut

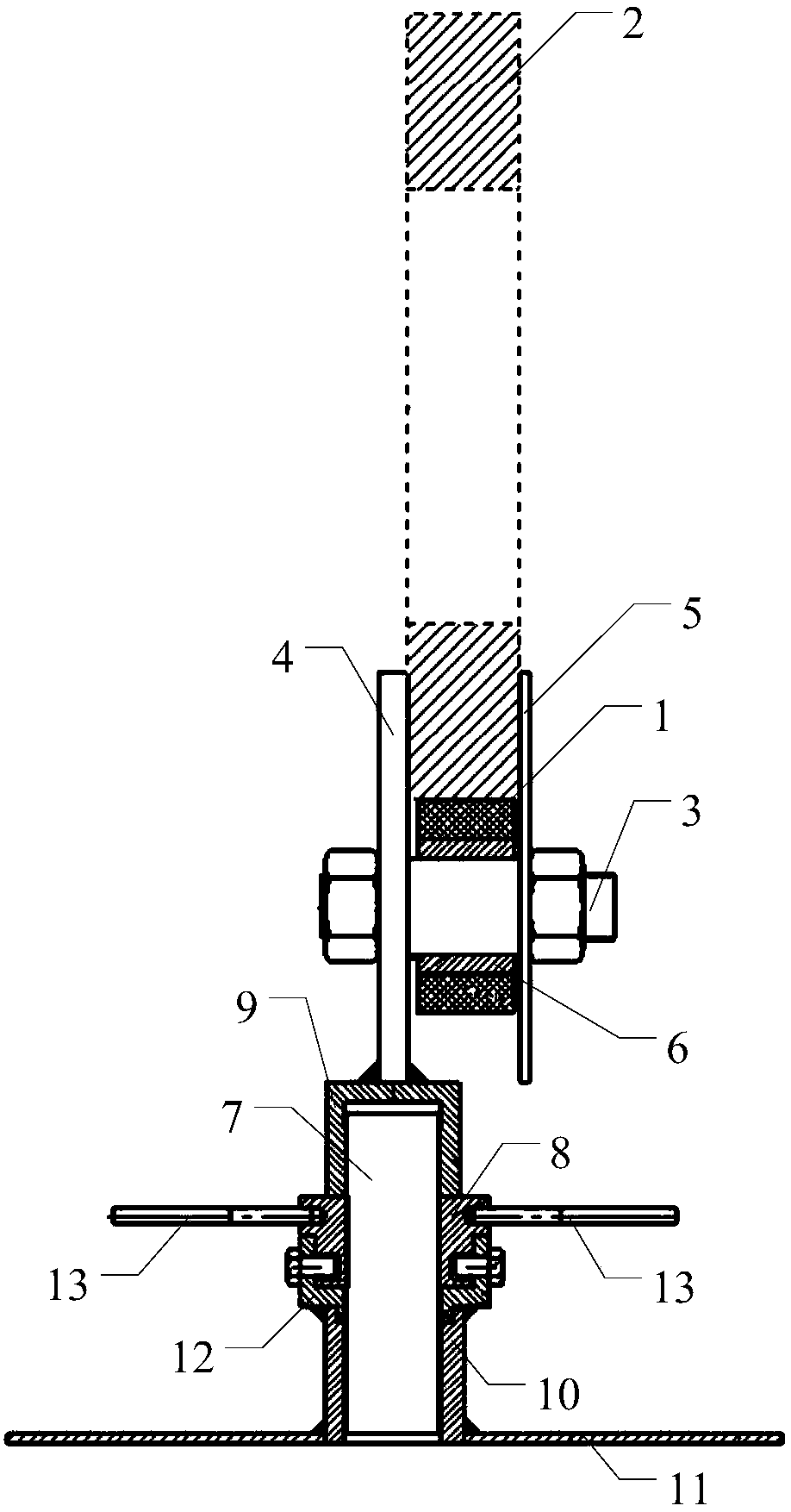

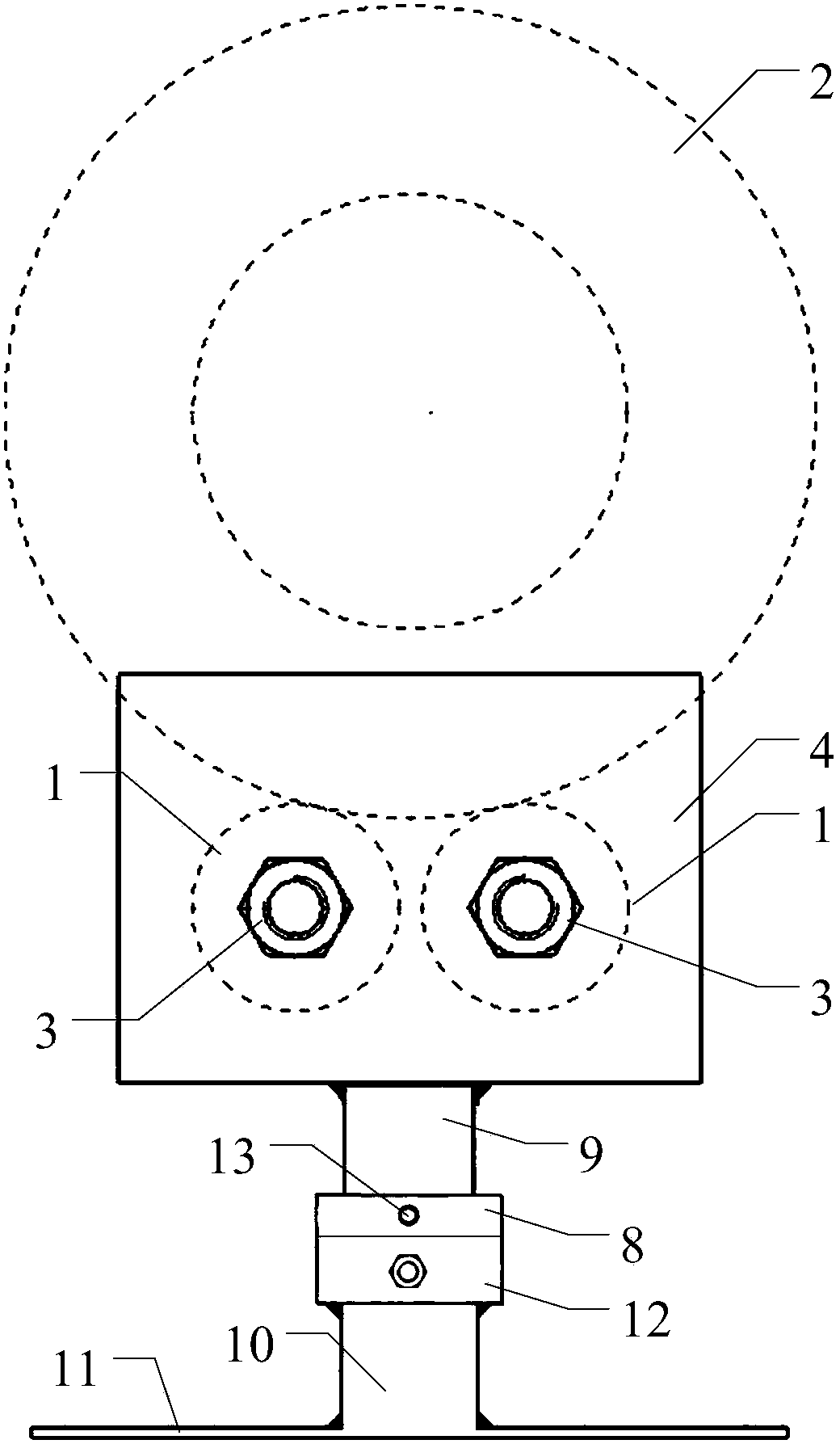

[0034] Such as figure 1 As shown, the structure diagram of the compressor rotor according to the present invention, the compressor rotor includes a main shaft 100 , and an impeller 200 and a large nut 2 respectively installed on the main shaft 100 .

[0035] Such as figure 2 , image 3 As shown, the compressor rotor big nut assembly bracket described in this embodiment includes a supporting part, a supporting part, and a lifting part, wherein: the supporting part is used to limit the position of the big nut; the supporting part is connected to the supporting part in rotation ; The supporting part is fixedly connected with the lifting part; the lifting part is a threaded screw lifting mechanism.

[0036] The rotating part include...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com