Seedling planting device having automatic feeding function

A seeding device and automatic feeding technology, applied in sowing, planter parts, filling of flower pots, etc., can solve the problems of increasing working time, reducing working efficiency, and taking a long time, so as to improve working efficiency and reduce manual work. effect of time

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0016] The present invention will be further described in detail below in conjunction with the drawings and specific embodiments.

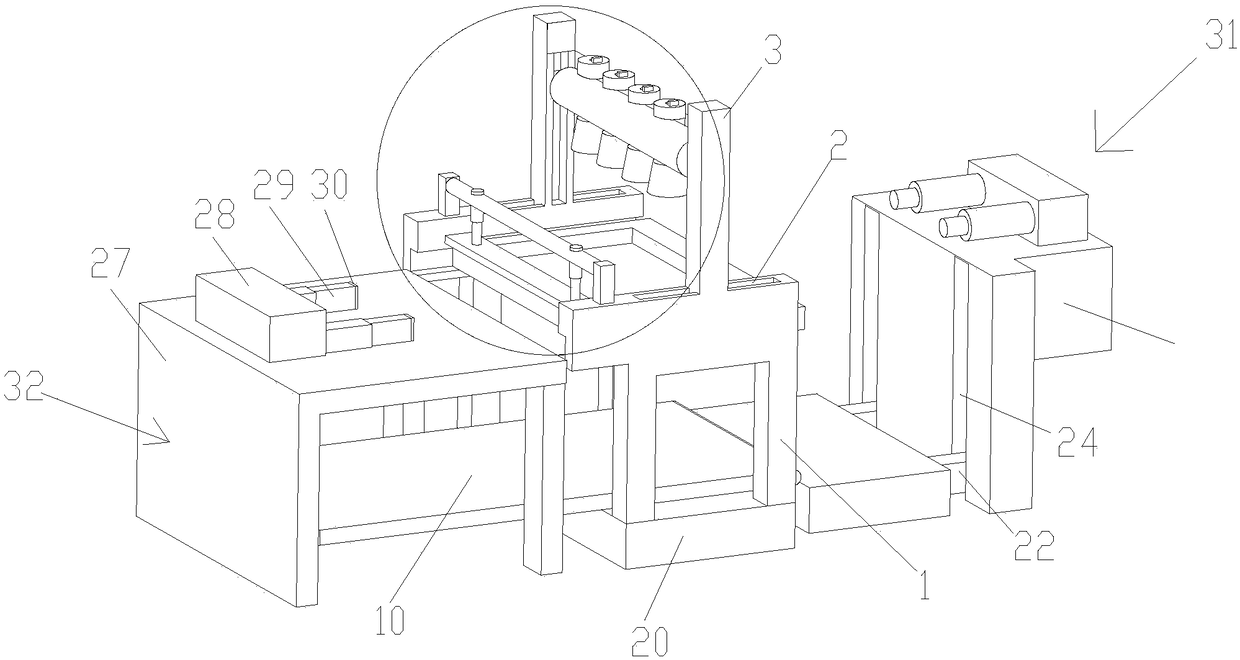

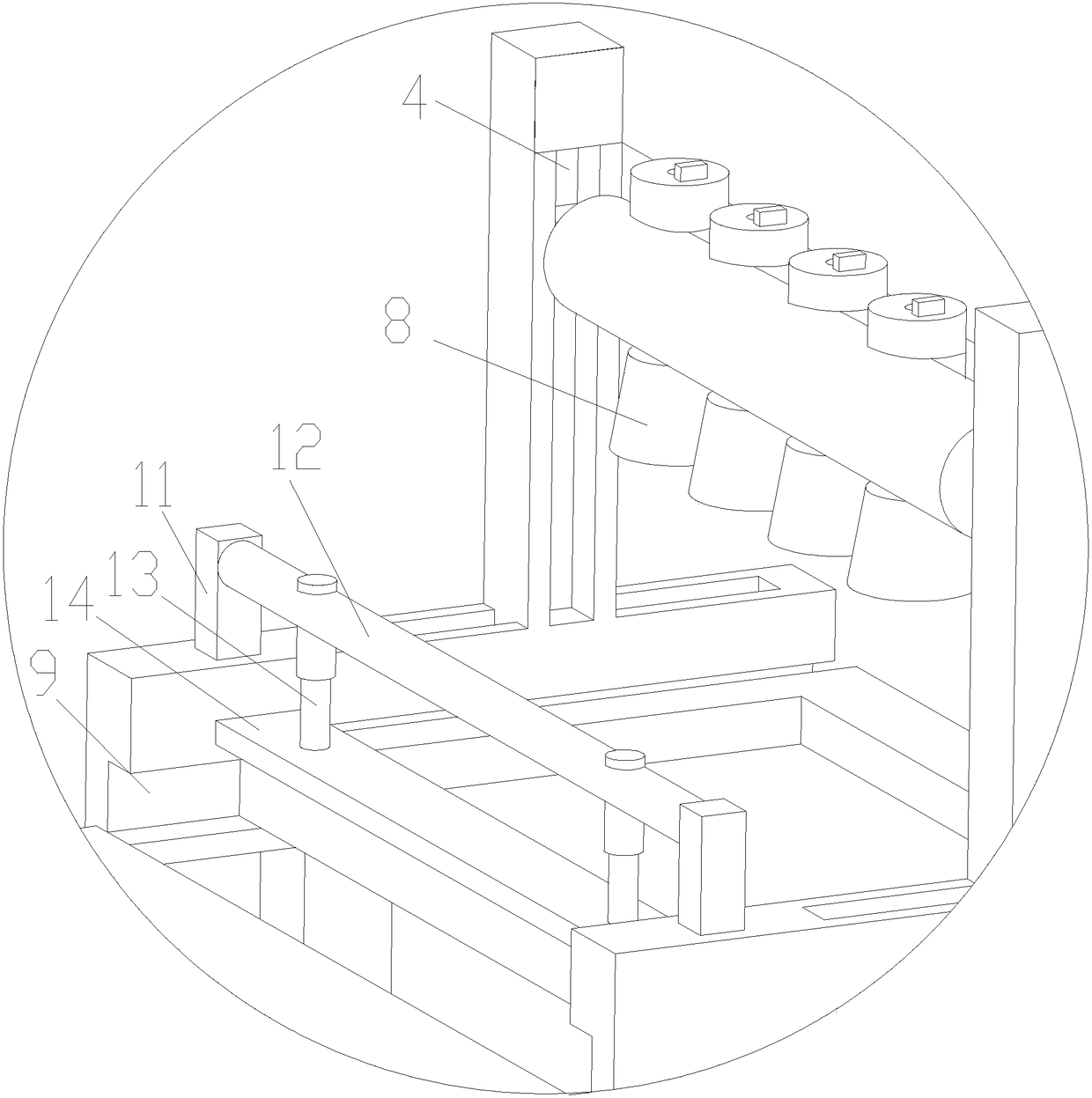

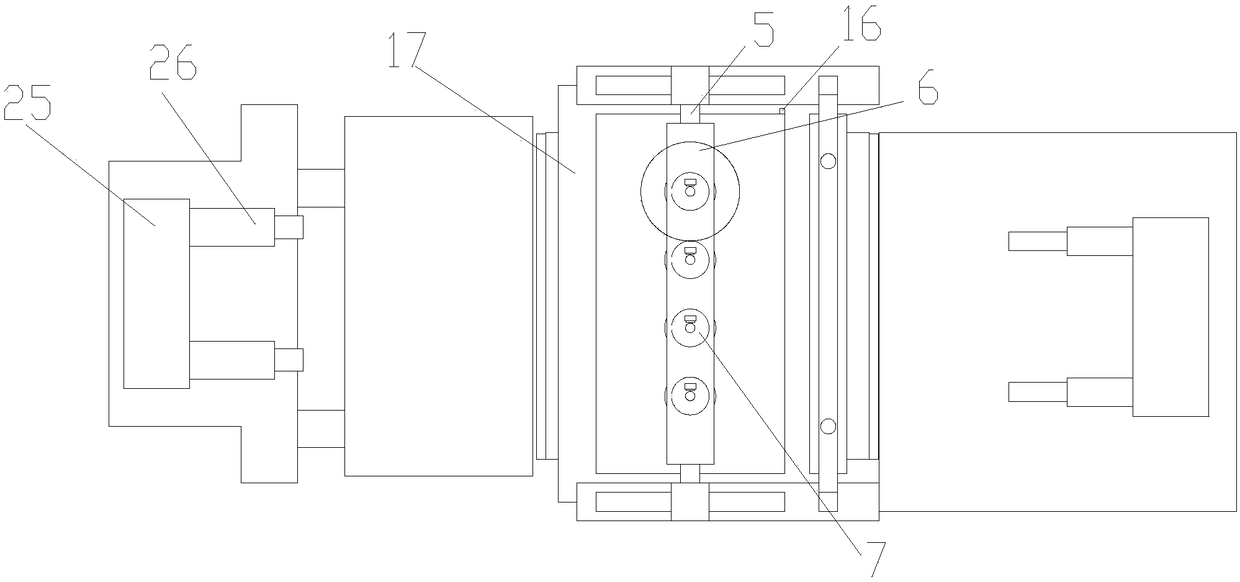

[0017] As attached Figure 1-4 The shown seedling planting device with automatic feeding function according to the present invention includes: a supporting frame 1, a base 20, a supporting slider 3, a digging and seeding mechanism 18, a conveyor belt 10, a supporting column 11, and a fixed column 12. The first telescopic rod 13, the squeezing block 14, the feeding mechanism 31, the suction mechanism 32; the bottom of the support frame 1 is provided with a base 20; the base 20 is provided with a conveyor belt 10; on the support frame 1 There are rail grooves 2 on both sides; a support slider 3 is slidably provided in the rail groove 2; a digging and seeding mechanism 18 that can slide up and down is provided between the two support sliders; the support slide One side of the block 3 is provided with a support column 11, and the above-mentioned support...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com