Electric-shock-preventive wall socket

A wall socket and anti-shock technology, which is applied in the direction of circuits, electrical components, fixed/insulated contact components, etc., can solve the problems of crowded space structure of the installation cavity, inconvenient assembly of parts, and limited movement range of the socket protection door.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

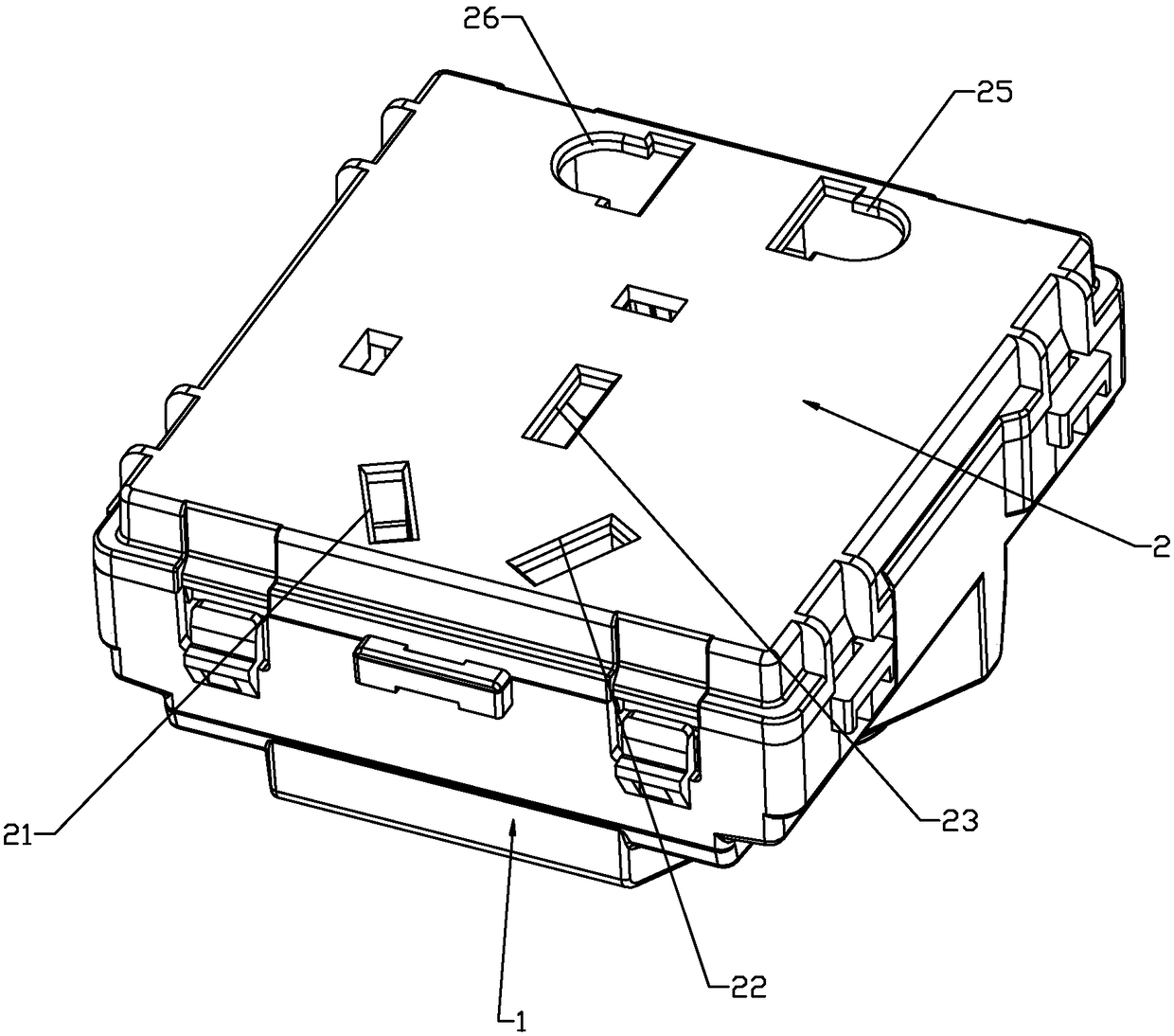

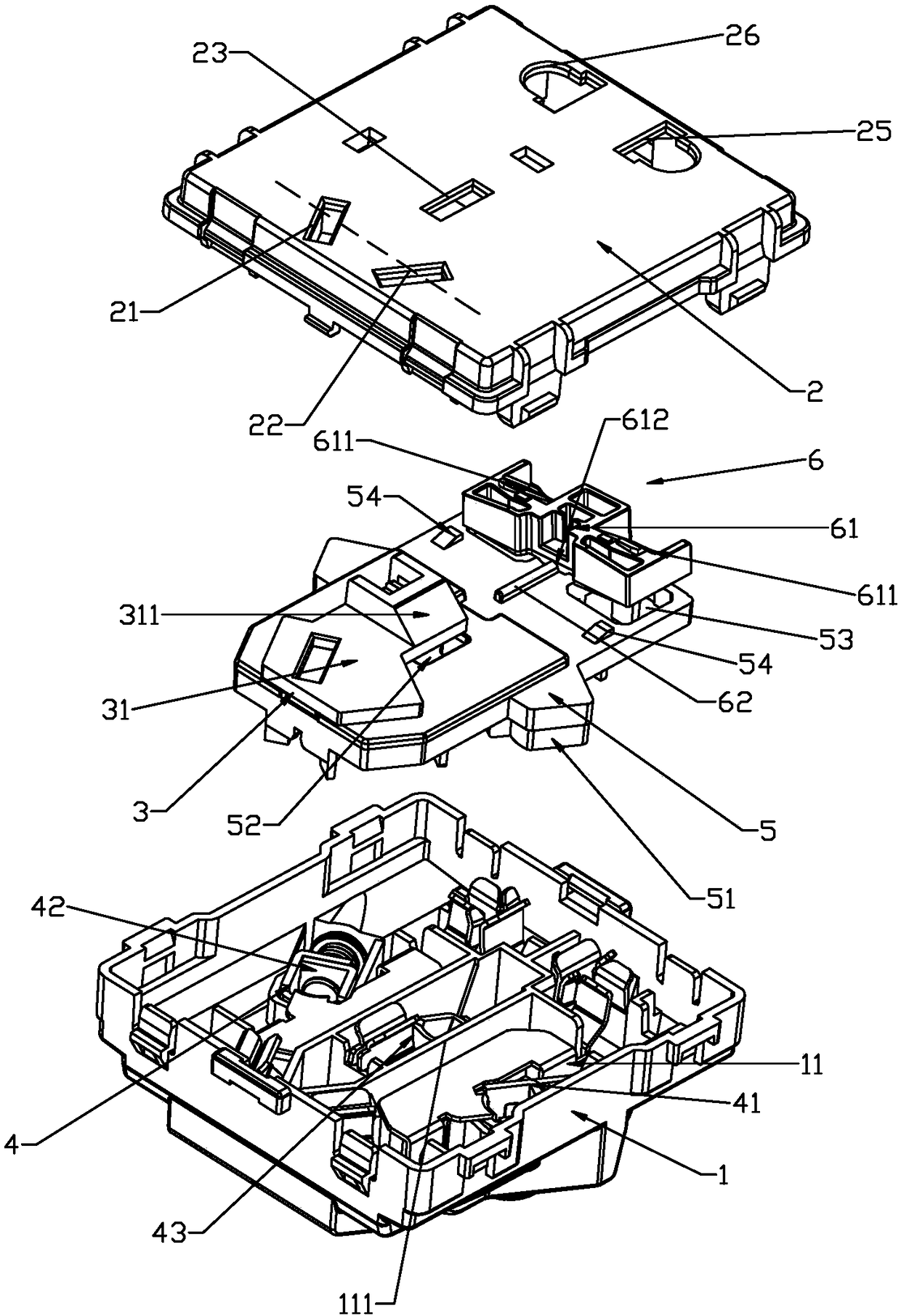

[0027] like figure 1 — Figure 4 As shown, the present invention discloses an electric shock-proof wall socket, including a base 1, a panel 2, a first electric shock-proof component 3 and an electrical connection component 4, the electrical connection component 4 and the first electric-shock protection component 3 are installed in the base 1, The panel 2 is provided with a first socket group for the plug to extend into and cooperate with the electrical connection assembly 4 to form a power supply. The first electric shock protection assembly 3 includes a first socket protection door 31, a first moving track 32 and a first reset member 33. The first The socket protection door 31 is blocked between the electrical connection assembly 4 and the first socket group and moves back and forth along the first moving track 32. The part of the first socket protection door 31 corresponding to the first socket group is arranged to move The track is away from the first extrusion slope 311 o...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com