Splicing door and window system

A splicing, door and window technology, applied in the installation of window glass, sealing device, arrangement of wing fan, etc., can solve the problems of inconvenient installation, high design and production cost, and many types of materials, so as to achieve convenient installation, labor-saving and design saving. Production cost, good aesthetics

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

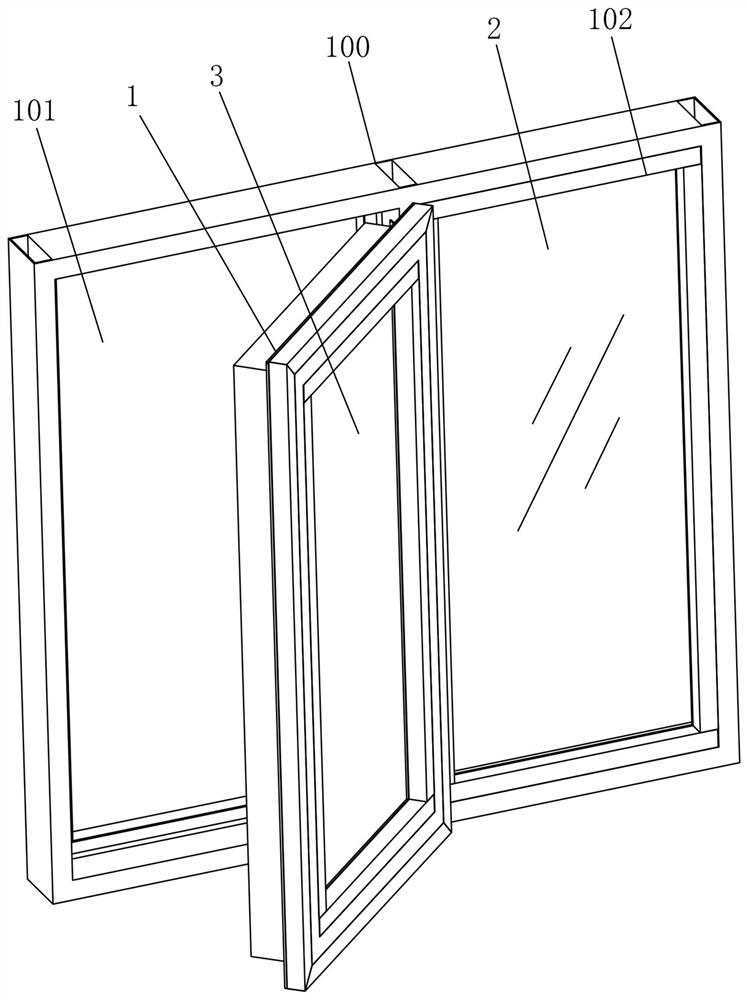

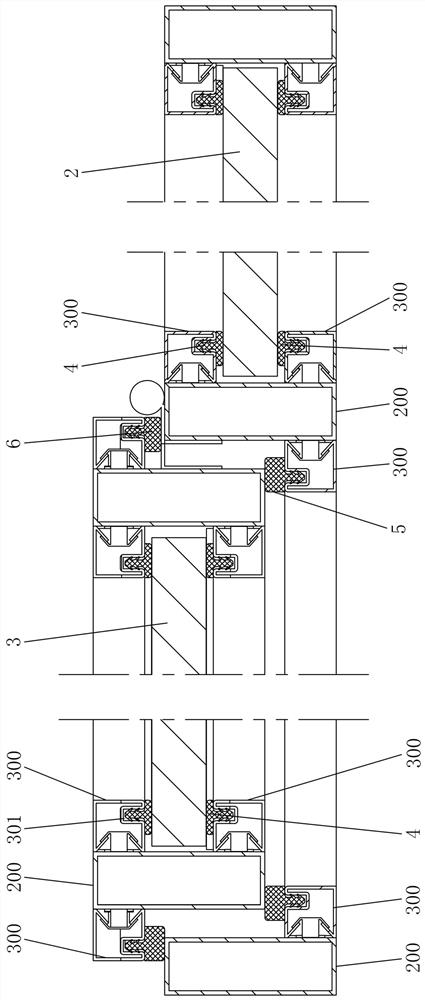

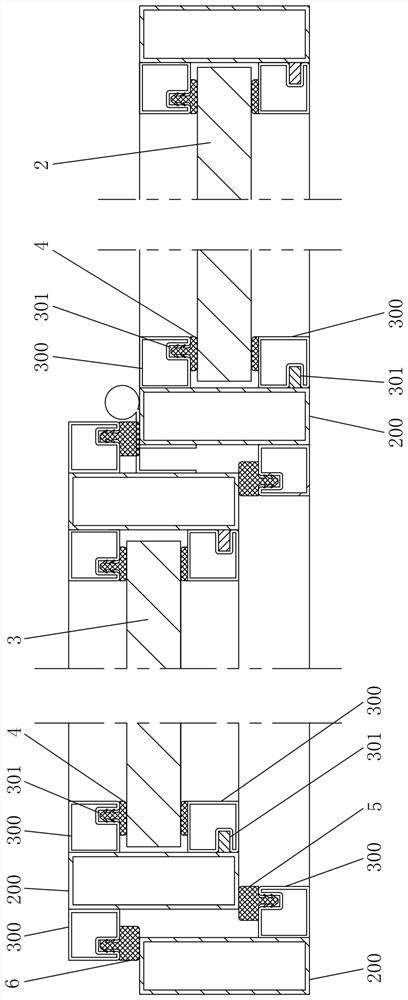

[0030] Such as figure 1 and figure 2 As shown, the splicing type door and window system of this embodiment includes a skeleton 100, the skeleton 100 has more than one fan frame 101 and more than one fixed frame 102, the window sashes 1 that can be opened are installed in the fan frame 101, and the second frame is installed in the fixed frame 102. A glass plate 2, the window sash 1 includes a frame body and a second glass plate 3 installed in the frame body, the frame body of the window sash 1 and the skeleton 100 are connected by a load-bearing beam 200, and the load-bearing beam 200 is composed of a beam body and at least two The limit parts are spliced together, and the load-bearing beams 200 around each fixed frame 102 are connected with two limit parts clamping and fixing the first glass plate 2 from both sides of the first glass plate 2, which encloses the load-bearing frame of the window sash 1. The beam 200 is connected with two stoppers clamping and fixing the seco...

Embodiment 2

[0040] The spliced door and window system of this embodiment is basically the same as that of Embodiment 1, the main difference is that, as image 3 As shown, in this embodiment, among the two strips 300 clamping and fixing the first glass plate 2, the groove 301 of one strip 300 is installed with the first sealing strip 4, and the groove 301 of the other strip 300 301 is socketed on the positioning column arranged on the bearing beam 200 . The strip 300 is socketed on the positioning column provided on the load-bearing beam 200 through its groove 301 , which is convenient for installation and positioning, and can be conveniently installed and improves the stability after installation. In other embodiments, the remaining strips 300 in the spliced door and window system can be sleeved on the positioning columns provided on the load-bearing beam 200 through the grooves 301 . The groove 301 of the strip 300 can be used not only as an installation groove for the seal, but als...

Embodiment 3

[0042]The spliced door and window system of this embodiment is basically the same as that of Embodiment 1, the main difference is that, as Figure 4 As shown, in this embodiment, the two stoppers for clamping and fixing the first glass plate 2 and the two stoppers for clamping and fixing the second glass plate 3 are respectively a retaining strip 400 and a buckle strip 500, and the retaining strip 400 Fixed on the load-bearing beam 200 , the buckle 500 is connected to the retaining bar 400 .

[0043] In this embodiment, the retaining strip 400 is fixedly connected to the load-bearing beam 200 by welding, and the buckle 500 is connected to the retaining strip 400 by clamping. In other embodiments, the retaining strip 400 may also be fixedly connected to the load-bearing beam 200 through a fastener connection, and the buckle 500 may also be connected to the retaining strip 400 through a fastener connection.

[0044] In this embodiment, the fourth sealing strip 7 is provided b...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com