Oilproof sole material and preparation method thereof

A shoe sole material and oil-proof technology, which is applied in shoe soles, footwear, applications, etc., can solve problems such as degummed soles, rubber swelling, and molecular structure destruction, and achieve improved comfort, oil-proof performance, good elasticity, and good oil resistance effect of effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

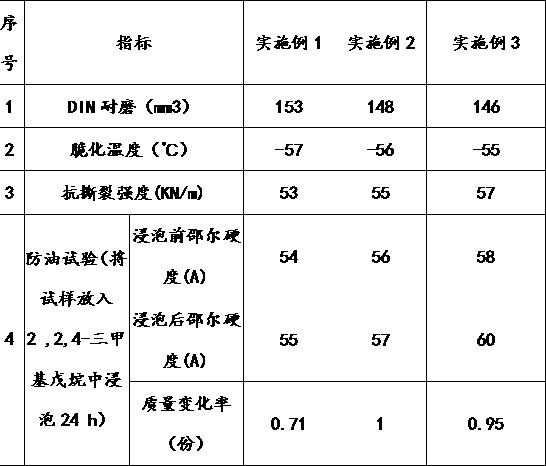

Examples

Embodiment 1

[0034] An oil-proof shoe sole material and a preparation method thereof, comprising the following raw materials in parts by weight:

[0035] APAO resin, 35 parts;

[0036] APP resin, 20 parts;

[0037] Nitrile rubber, 5 parts;

[0038] fiberglass, 20 parts

[0039] calcium carbonate, 6 parts;

[0040] Calcium stearate, 2 parts;

[0041] Bis(2,2,6,6-tetramethyl-4-piperidinyl) sebacate, 0.5 parts.

[0042] (3) The heat stabilizer is a mixture of calcium stearate and zinc stearate in a ratio of 1:1.

[0043] A preparation method for oil-resistant sole material, comprising the steps of:

[0044] (1) Take by weighing 35 parts of APAO resins, 20 parts of APP resins, 5 parts of nitrile rubber, 20 parts of glass fibers,

[0045] The raw materials of 6 parts of calcium carbonate, 3 parts of calcium stearate and 0.5 part of bis(2,2,6,6-tetramethyl-4-piperidinyl) sebacate are for use;

[0046] (2) Put each raw material weighed in the step (1) into a vacuum oven for drying respect...

Embodiment 2

[0050] An oil-proof shoe sole material and a preparation method thereof, comprising the following raw materials in parts by weight:

[0051] APAO resin, 40 parts;

[0052] APP resin, 25 parts;

[0053] Nitrile rubber, 7 parts;

[0054] fiberglass, 23 servings

[0055] calcium carbonate, 7 parts;

[0056] Calcium Stearate, 3 parts;

[0057] Bis(2,2,6,6-tetramethyl-4-piperidinyl) sebacate, 1 part.

[0058] (3) The heat stabilizer is a mixture of calcium stearate and zinc stearate in a ratio of 1:1.

[0059] A preparation method for oil-resistant sole material, comprising the steps of:

[0060] (1) Take by weighing 40 parts of APAO resin, 25 parts of APP resin, 7 parts of nitrile rubber, 23 parts of glass fiber,

[0061] The raw materials of 7 parts of calcium carbonate, 3 parts of calcium stearate and 1 part of bis(2,2,6,6-tetramethyl-4-piperidinyl) sebacate are for use;

[0062] (2) Put each raw material weighed in the step (1) into a vacuum oven for drying respectively...

Embodiment 3

[0066] An oil-proof shoe sole material and a preparation method thereof, comprising the following raw materials in parts by weight:

[0067] APAO resin, 45 parts;

[0068] APP resin, 27 parts;

[0069] Nitrile rubber, 10 parts;

[0070] fiberglass, 28 servings

[0071] Calcium carbonate, 10 parts;

[0072] Calcium stearate, 2 parts;

[0073] Bis(2,2,6,6-tetramethyl-4-piperidinyl) sebacate, 1.5 parts.

[0074] (3) The heat stabilizer is a mixture of calcium stearate and zinc stearate in a ratio of 1:1.

[0075] A preparation method for oil-resistant sole material, comprising the steps of:

[0076] (1) Weigh 45 parts of APAO resin, 27 parts of APP resin, 10 parts of nitrile rubber, 28 parts of glass fiber, 10 parts of calcium carbonate, 2 parts of calcium stearate and 1.5 parts of bis(2,2,6,6- The raw material of tetramethyl-4-piperidinyl) sebacate is stand-by;

[0077] (2) Put each raw material weighed in step (1) into a vacuum drying oven for drying respectively, the d...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com