Apparatus and method for producing scaly material from mineral melt

A scale-like and melt-like technology, which is applied in the production of scale-like materials from gabbro minerals and in the field of basalt, can solve the problems of uneven scale area and thickness, high consumption of materials and resources, and difficult separation of scales. The effect of uniform area and thickness, low material and resource consumption, and easy industrial application

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

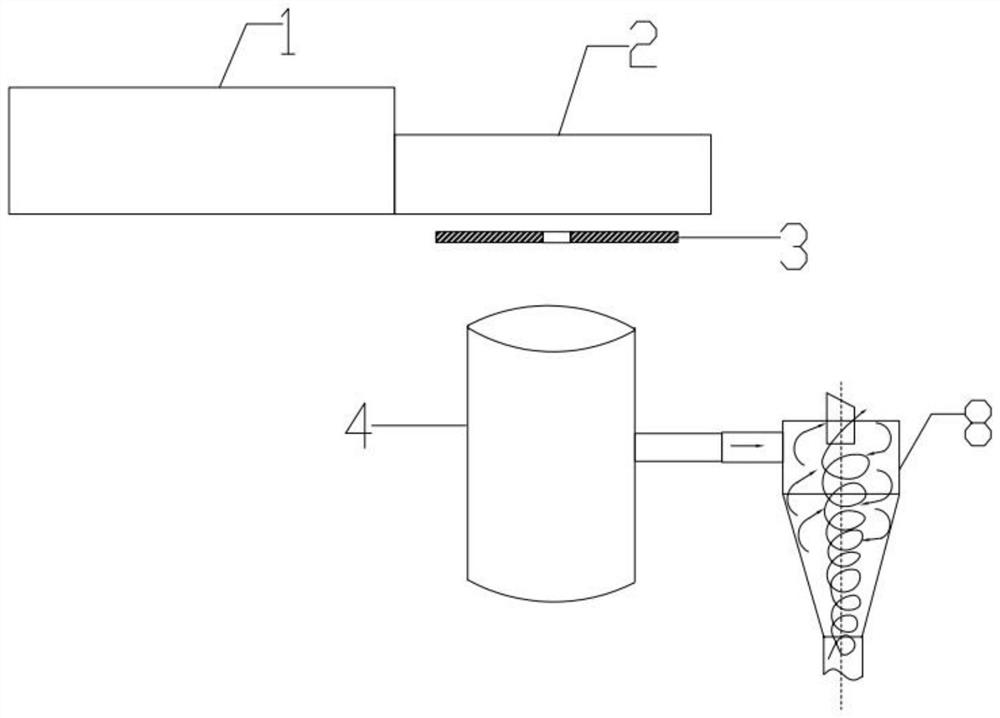

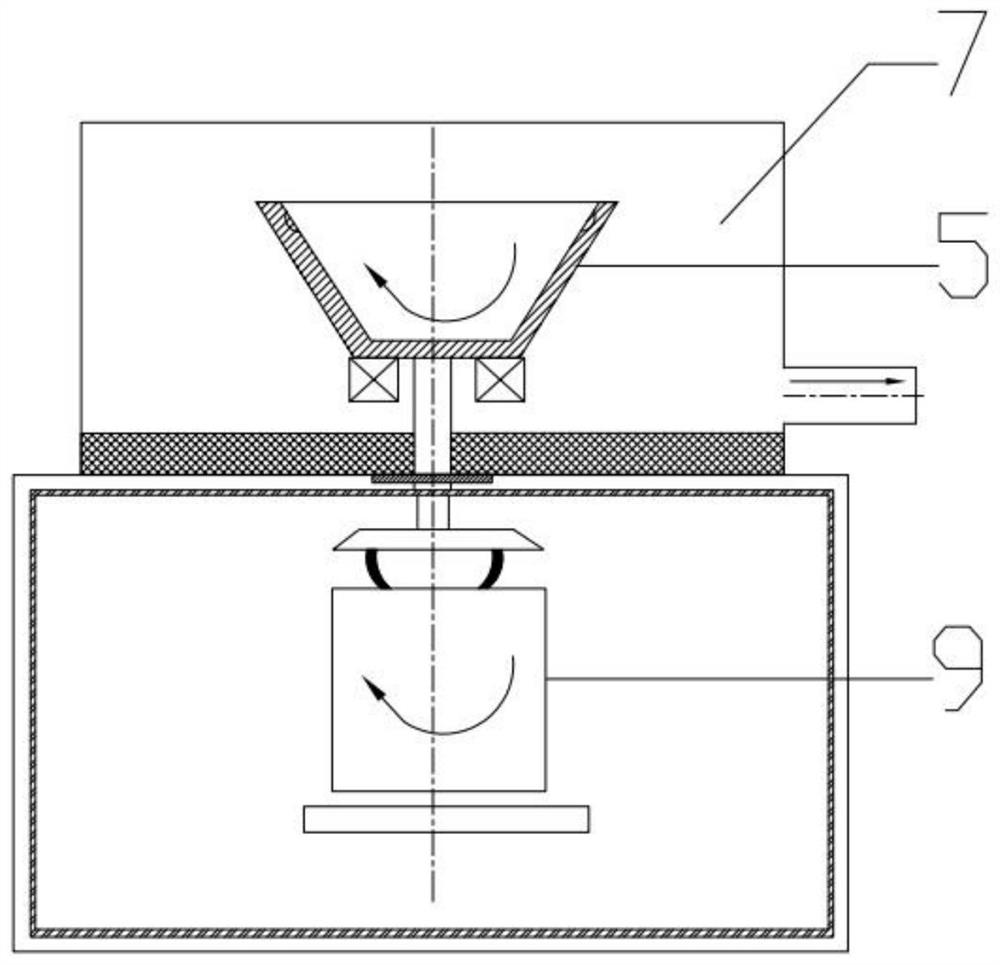

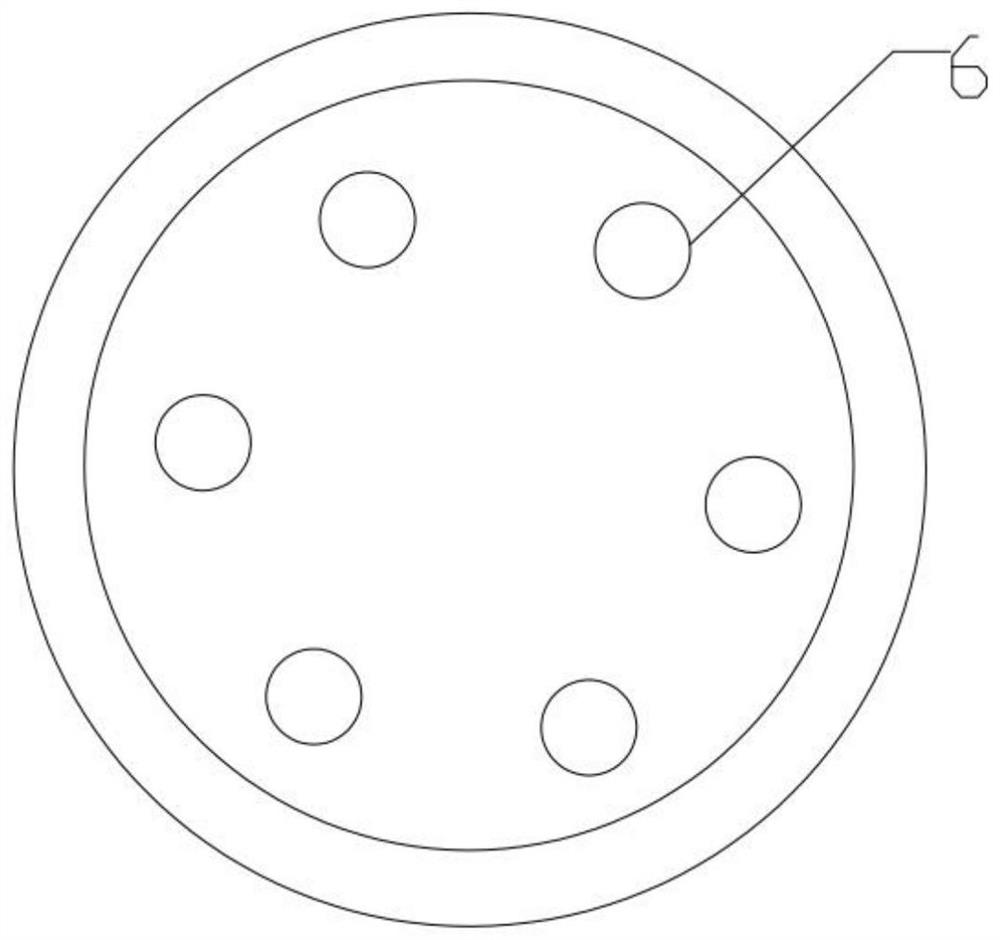

[0037] A device for producing scaly materials from mineral melts, such as Figure 1~3 As shown, it includes a furnace 1 and a feeder 2. The outlet of the furnace is connected to the inlet of the feeder. A high-temperature-resistant alloy plate 3 is arranged below the outlet of the feeder. The center of the high-temperature-resistant alloy plate A through hole with a diameter of 4-10 mm is provided. A scale forming device 4 is provided under the high temperature resistant alloy plate. The outlet of the scale forming device is connected with the cyclone separator 8. The scale forming device includes a scale collecting bin 7, a funnel The rotating dispersing disc 5 and the motor 9 that drives the rotating dispersing disc to rotate, the rotating dispersing disc is set inside the scale collection bin, and the top surface of the scale collecting bin above the rotating dispersing disc is provided with a through hole in the center of the high temperature resistant alloy plate For matc...

Embodiment 2

[0040] A method of producing a scaly material from a mineral melt comprising the steps of:

[0041] 1) Put the ground and prepared basalt raw materials into a furnace, heat at 1300°C to melt the raw materials to obtain a melt, and homogenize it;

[0042] 2) Step 1) The homogenized melt obtained in the melting furnace enters the feeder, and the melt at the outlet of the feeder falls to the electrically heated high-temperature-resistant alloy plate under its gravity and spreads in a thin film. The high-temperature alloy plate is heated to 1300-1480°C by means of a DC transformer, and then forms a fine melt flow through the through hole in the center of the high-temperature-resistant alloy plate;

[0043] 3) The melt flow obtained in step 2) continues to fall through the opening on the top of the scale collection bin to the rotating rotating dispersing disc under the action of gravity, and the rotating dispersing disc rotates at a speed of 250m / min. The jet hole continuously sup...

Embodiment 3

[0046] A method of producing a scaly material from a mineral melt comprising the steps of:

[0047] 1) Put the ground and prepared basalt raw materials into a furnace, heat at 1500°C to melt the raw materials to obtain a melt, and homogenize it;

[0048] 2) Step 1) The homogenized melt obtained in the melting furnace enters the feeder, and the melt at the outlet of the feeder falls to the electrically heated high-temperature-resistant alloy plate under its gravity and spreads in a thin film. The high-temperature alloy plate is heated to 1300-1480°C by means of a DC transformer, and then forms a fine melt flow through the through hole in the center of the high-temperature-resistant alloy plate;

[0049] 3) The melt flow obtained in step 2) continues to fall through the opening on the top of the scale collection bin to the rotating rotating dispersing disc under the action of gravity. The hole continuously supplies compressed air pulses, the frequency of compressed air pulses i...

PUM

| Property | Measurement | Unit |

|---|---|---|

| diameter | aaaaa | aaaaa |

| size | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com