No-wire-harness connection structure

A connection structure and wireless technology, which is applied in the direction of support structure installation, electrical equipment construction parts, electrical components, etc., can solve the problems of low aesthetics, small space for aerial insertion welding, and reduced production availability, so as to avoid welding too many lines Cables and layouts are highly consistent, avoiding wiring errors

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0033] The present invention will be described in further detail below in conjunction with the accompanying drawings and specific embodiments.

[0034] The invention provides a wireless binding device applied in a case, which is used for optimizing the wiring inside the case.

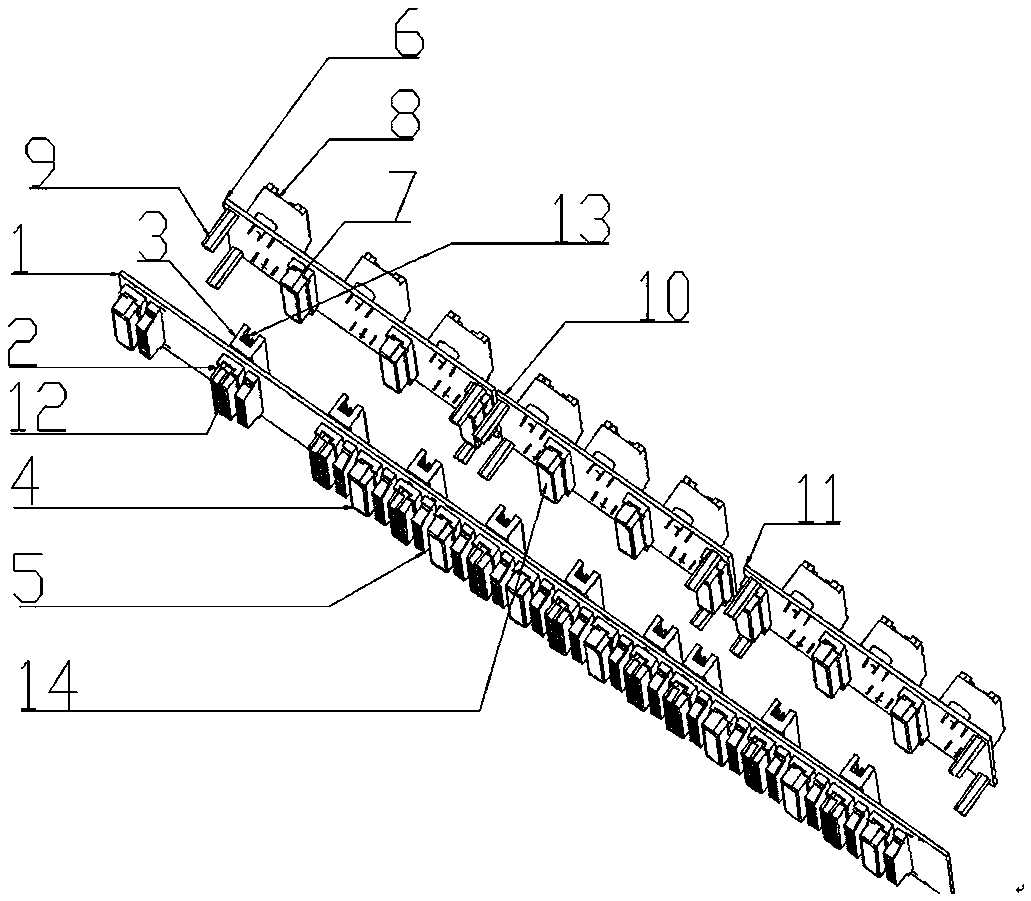

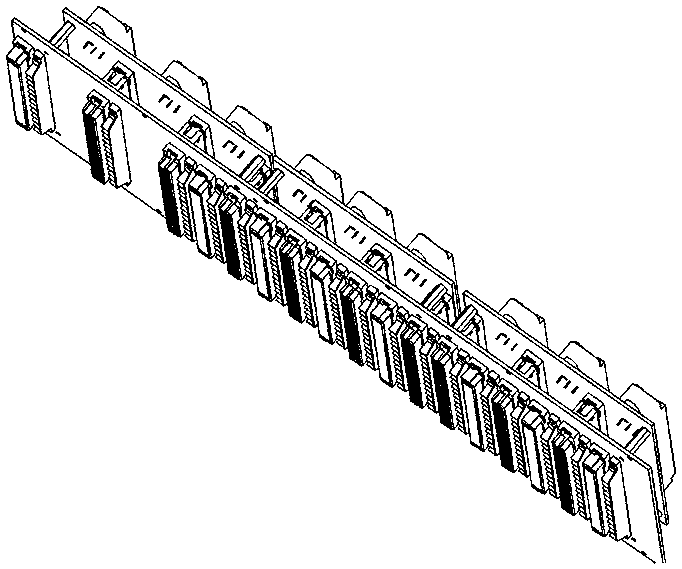

[0035] The device of the present invention includes a motherboard 1 and a backplane, and the motherboard 1 is provided with a long-pin connector L2. Both the above-mentioned setting method and the following setting method can choose a fixed setting method or a non-fixed setting method, and a welding method can be selected for a fixed setting method.

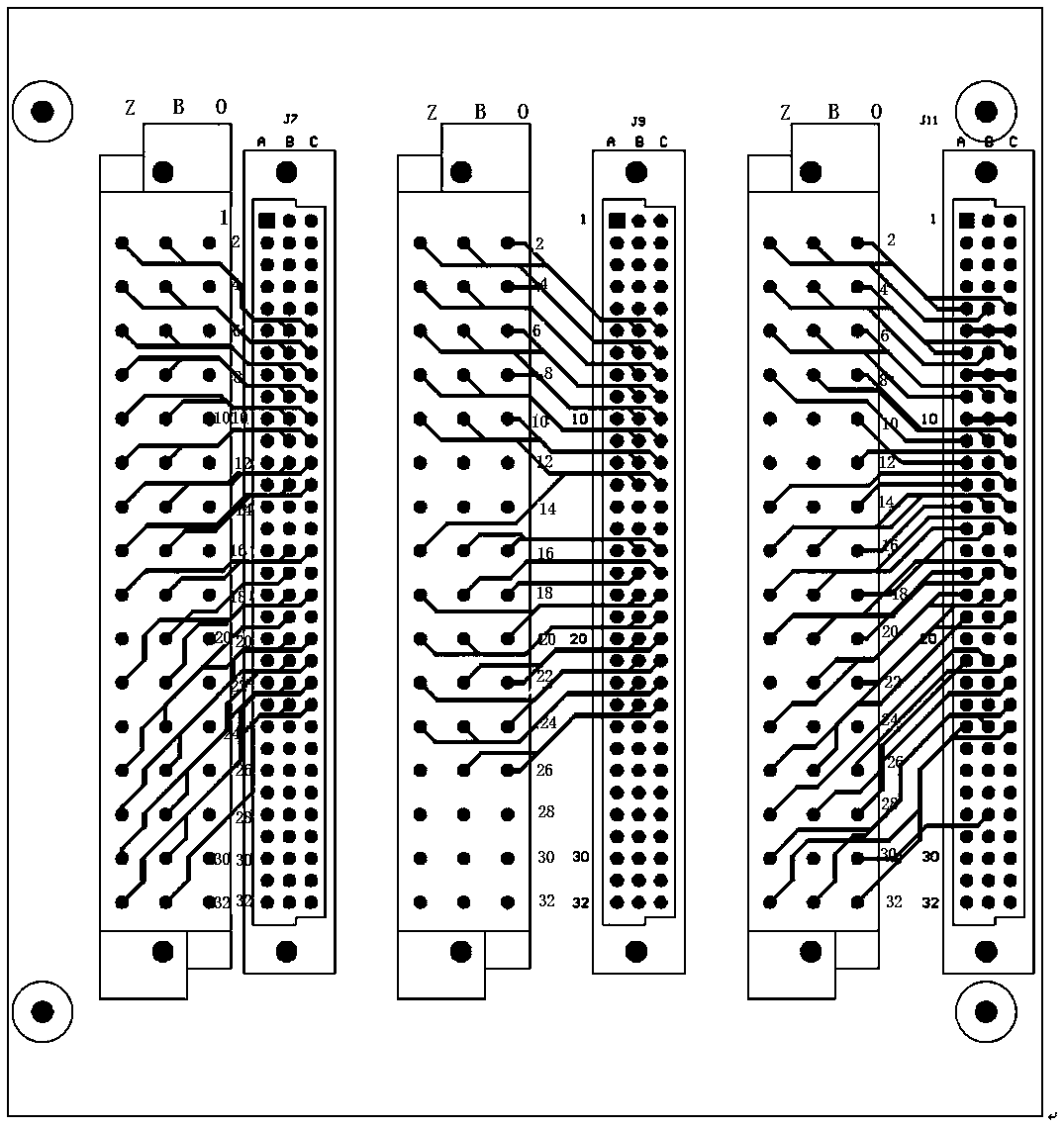

[0036] The connector pins of the connector L2 penetrate the other side of the motherboard 1, and then penetrate the other side of the backplane connected to the motherboard 1, and then connect to the connector M8 through the printed lines on the backplane.

[0037] That is, the printed lines are arranged on the backboard of the present invention, and the ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com