Device for on-load testing and precision calibration of steering engine component

A unit and precision technology, which is applied in the testing, measuring devices, instruments and other directions of machines/structural components, can solve the problems of inability to perform precision calibration, screening, high cost and high cost of high-precision sensors, and achieve simple structure, convenient operation, The effect of high coaxiality

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0046] The present invention is further described below in conjunction with accompanying drawing.

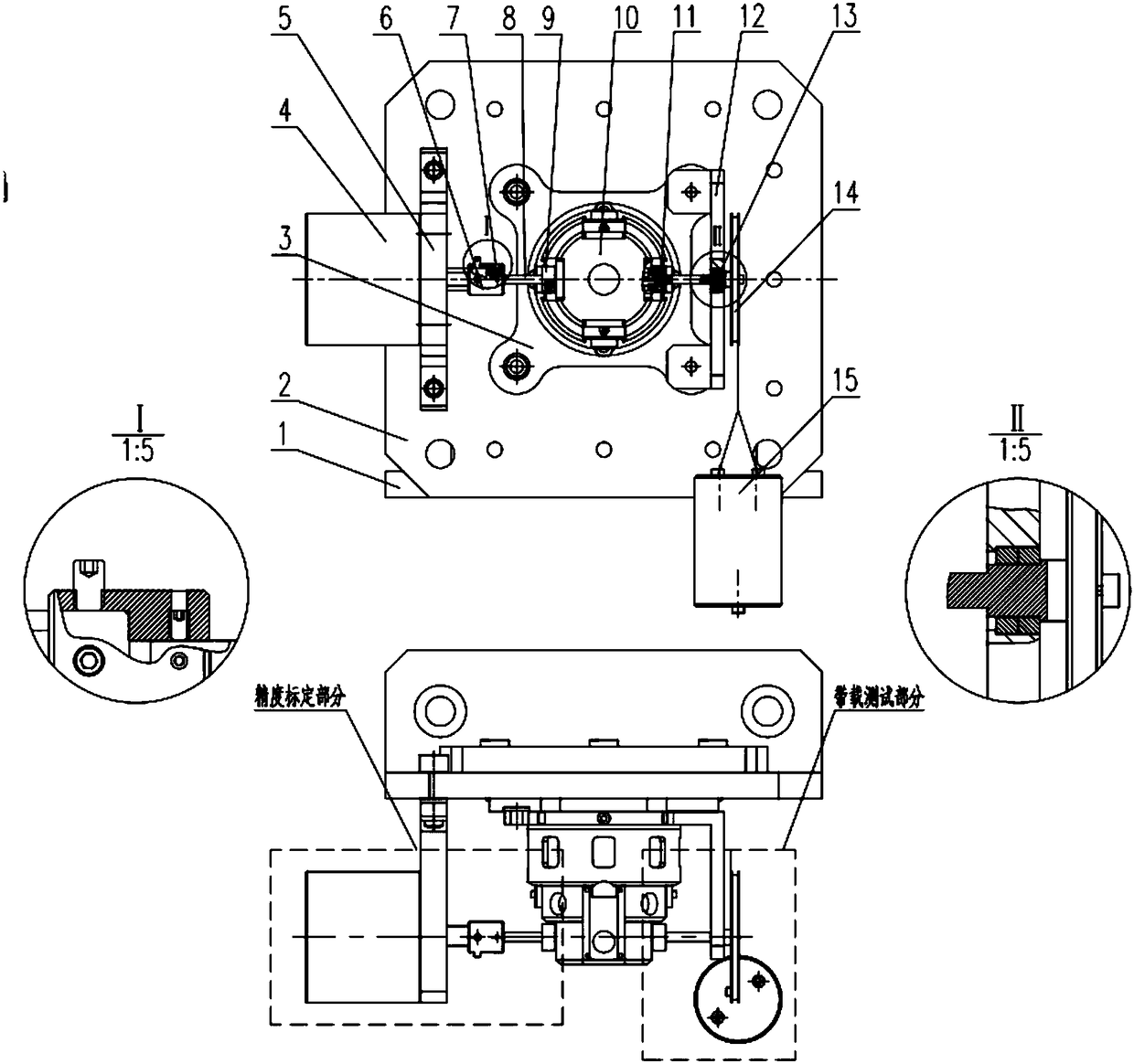

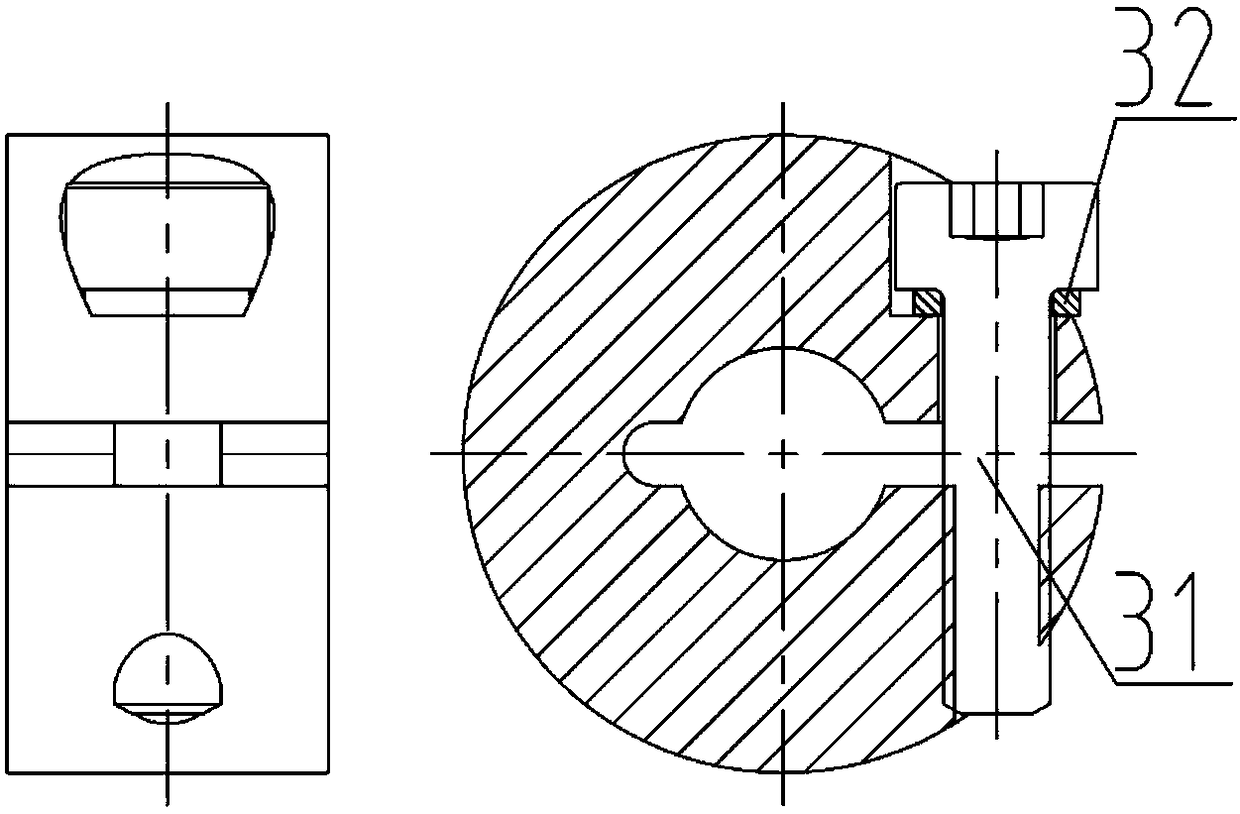

[0047] The system composition in this embodiment is as follows Figure 1-Figure 6shown. The on-load test and precision calibration components involved in the system include a fixed plate 1, a base plate 2, a connecting plate 3, a high-precision encoder 4, an encoder bracket 5, a precision coupling 6, a set screw 7, a connecting shaft 8, a A rigid coupling 9, a steering gear assembly 10, a second rigid coupling 11, a support plate 12, a bearing 13, a rotating disk 14, and a weight 15; when the device is operated, the fixed plate 1 and the The horizontal workbench is fixedly connected, the base plate 2 is fixedly connected with the fixed plate 1, and placed parallel to the edge of the workbench, the connecting plate 3 is fixedly connected with the base plate 2 through four screws, and the connecting plate 3 has a mounting seat for the steering gear assembly 10 The installation p...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com