Fixing structure with blade radial size and rotating angle adjusting function

A technology of radial dimension and rotation angle, which is applied in the directions of machines/engines, liquid fuel engines, pumping devices for elastic fluids, etc., and can solve problems such as inability to realize adjustment functions

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

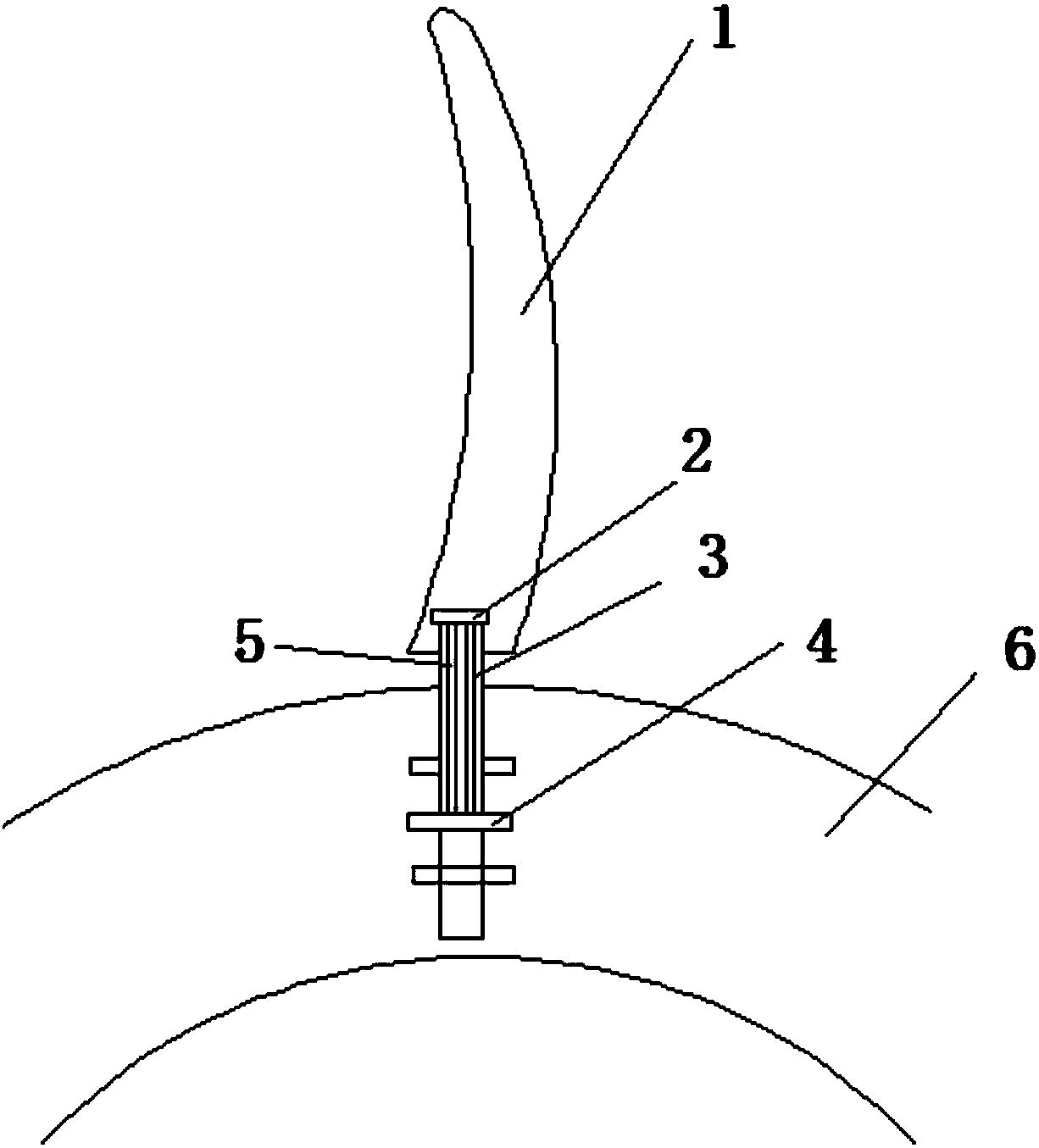

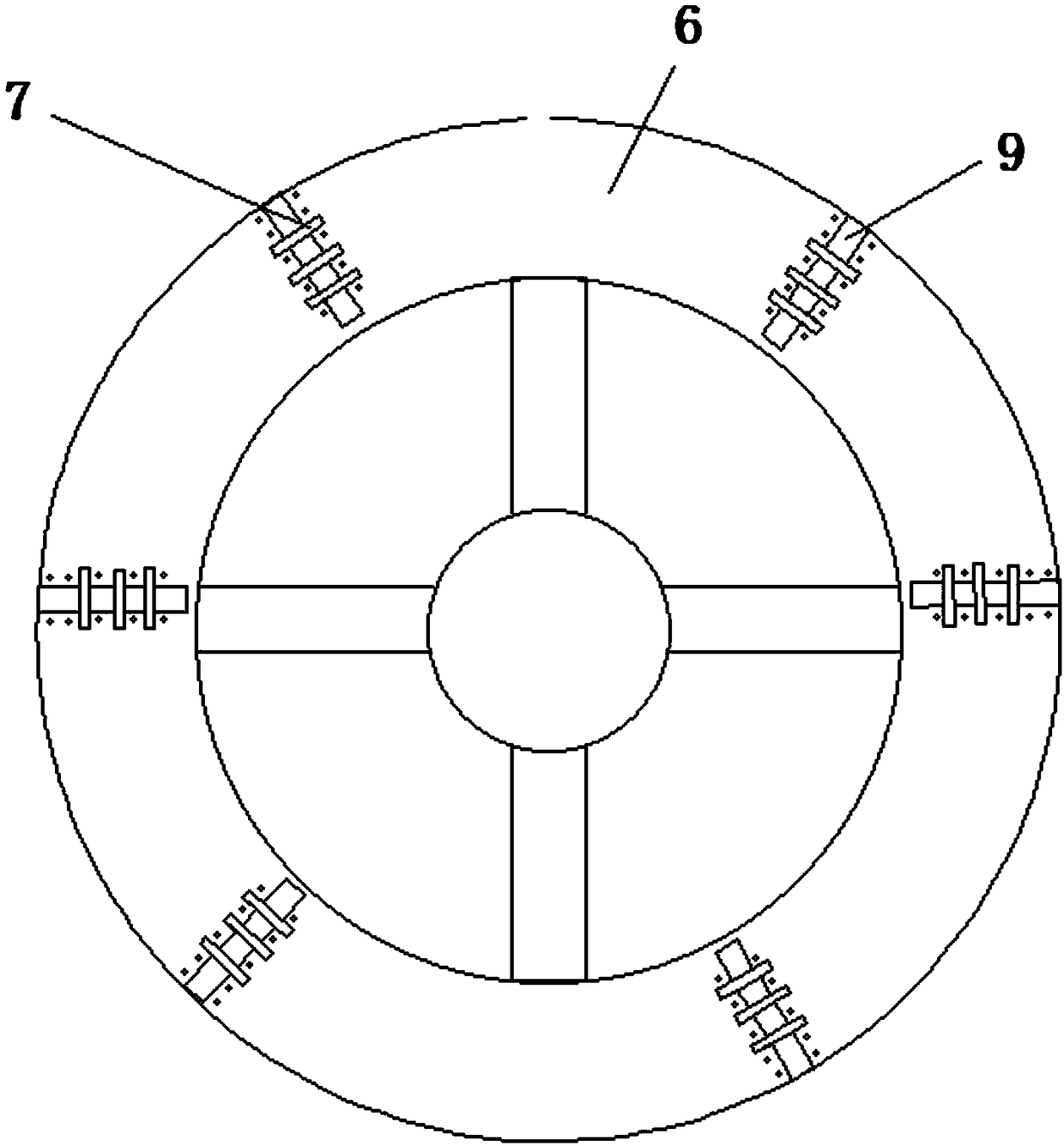

[0012] The present invention will be described in detail below in conjunction with the accompanying drawings. As shown in the figure, a connecting portion is provided below the blade 1, and the connecting portion includes an upper convex ring 2 and a lower convex ring 4, and an axle shaft is between the upper convex ring 2 and the lower convex ring 4. 3. The outer side of the shaft 3 is axially provided with convex ribs 5; the upper convex ring 2 is embedded in the blade, and the lower convex ring 4 is arranged in the corresponding groove 7 of the hub 6; the wheel cover 8 is also provided with corresponding The groove of the wheel cover 8 corresponds to the groove of the wheel hub 6 to fasten the lower convex ring, and the wheel cover 8 is fixed on the wheel hub 6 by bolts 10; Strip grooves 9; multiple groups of grooves 7 are arranged radially on the hub and the wheel cover.

[0013] Another hub structure is: the hubs are two sets of concentric circle structures, the outer hub...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com