Dry fermentation bed system for municipal sludge

A technology of municipal sludge and fermentation bed, applied in biological sludge treatment, dewatering/drying/concentrated sludge treatment, etc., can solve the problems of turning and distributing obstacles, the height of the distributing turning device cannot be adjusted, and hardening, etc. To achieve the effect of convenient transfer, stirring and conveying, and avoid excessive compaction

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0034] In order to make the purpose, technical solution and advantages of the present invention clearer, the invention will be clearly and completely described below in conjunction with the accompanying drawings and specific embodiments.

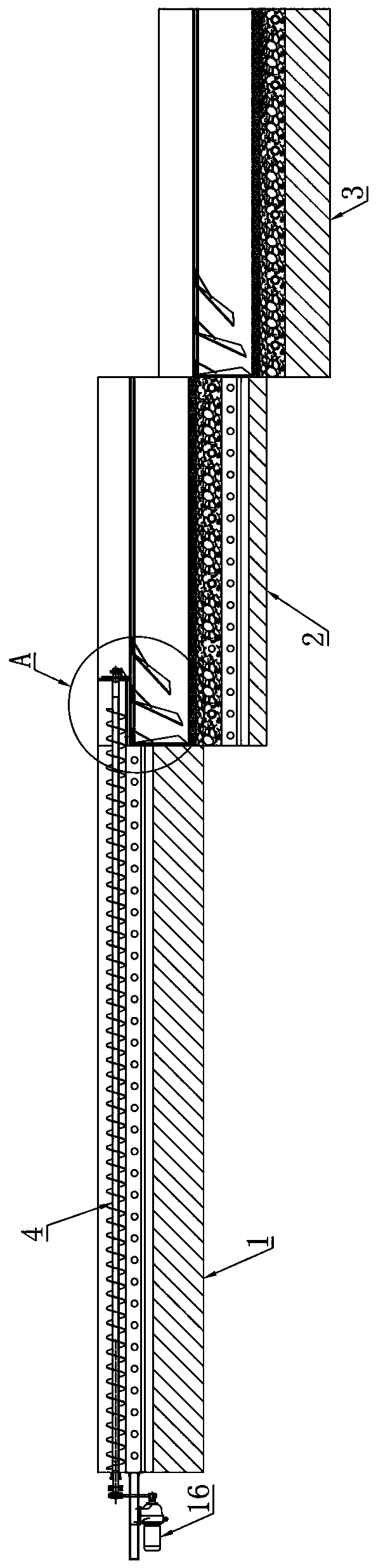

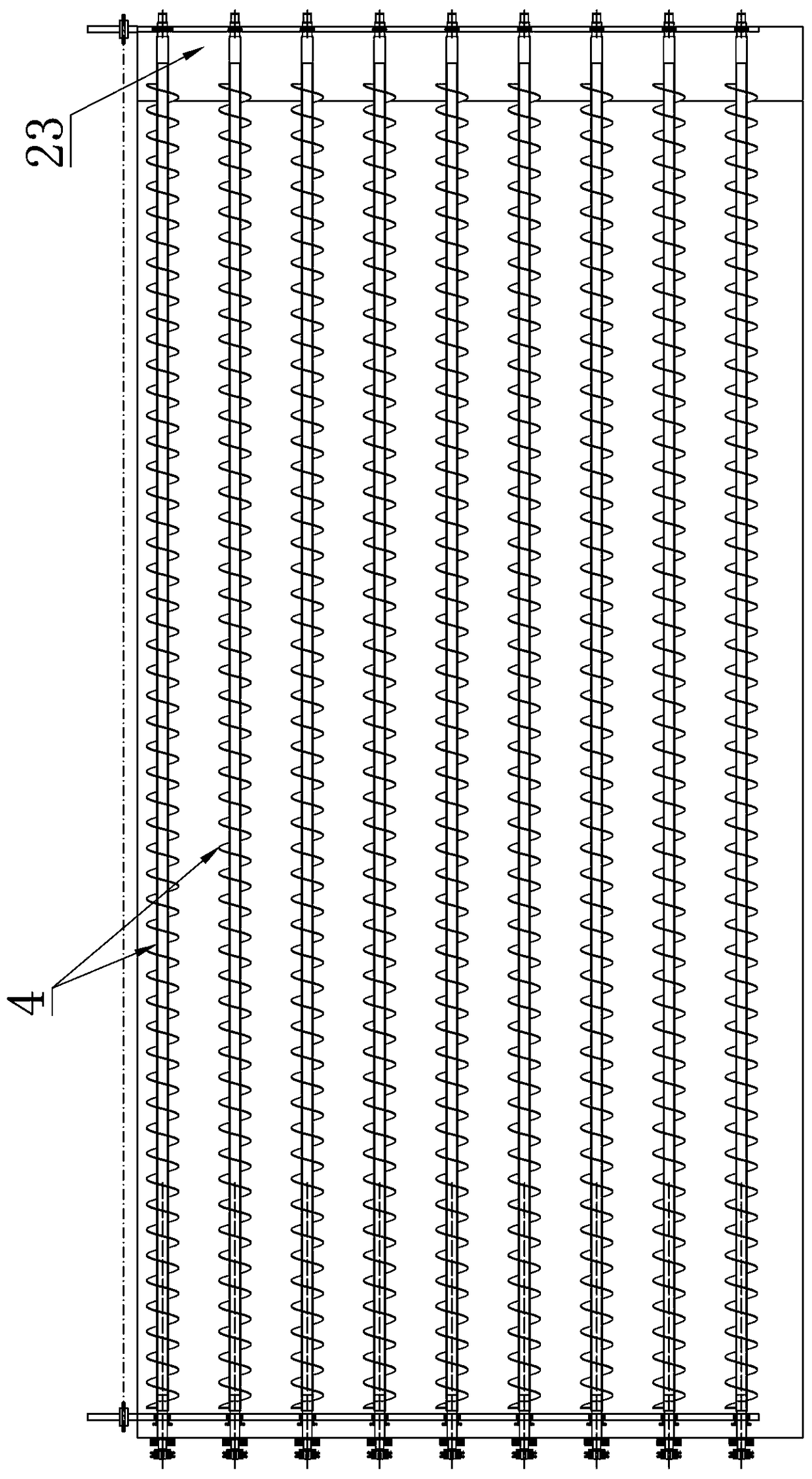

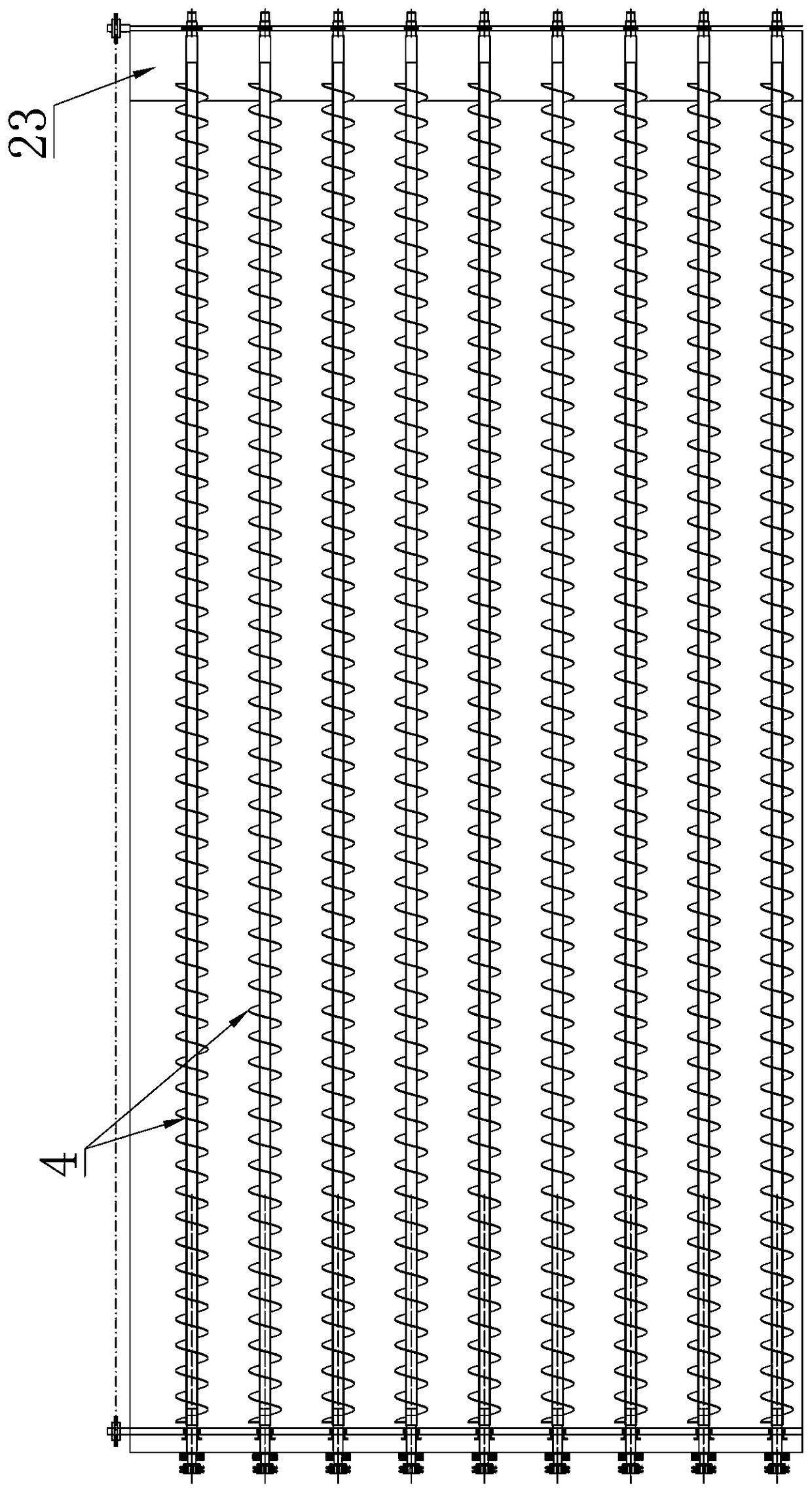

[0035] Such as Figure 1-8 A municipal sludge drying fermentation bed system shown includes a drying fermentation bed, and the drying fermentation bed includes a drying pretreatment area 1, a fermentation degradation area 2 and an aging stabilization area 3 arranged in sequence. The specific layered structure of the drying pretreatment zone 1, fermentation degradation zone 2 and aging stability zone 3 refers to the Chinese invention patent with the patent number 201410272977.9 and the subject name of a fermentation bed system for drying organic solid waste.

[0036]In this embodiment, the drying pretreatment area 1, the fermentation degradation area 2 and the aging stability area 3 are arranged in steps from high to low; a concrete foundatio...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com