Bent roller cylinder auxiliary tool capable of being fast dismounted or mounted and use method thereof

An auxiliary tool and roll bending technology, which is applied in the field of quick disassembly and assembly bending cylinder auxiliary tools, can solve the problems of torque limitation, great difficulty in disassembling and installing the bending cylinder, etc., so as to improve disassembly efficiency and disassembly adaptability The effect of broad, economical and technical effects

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

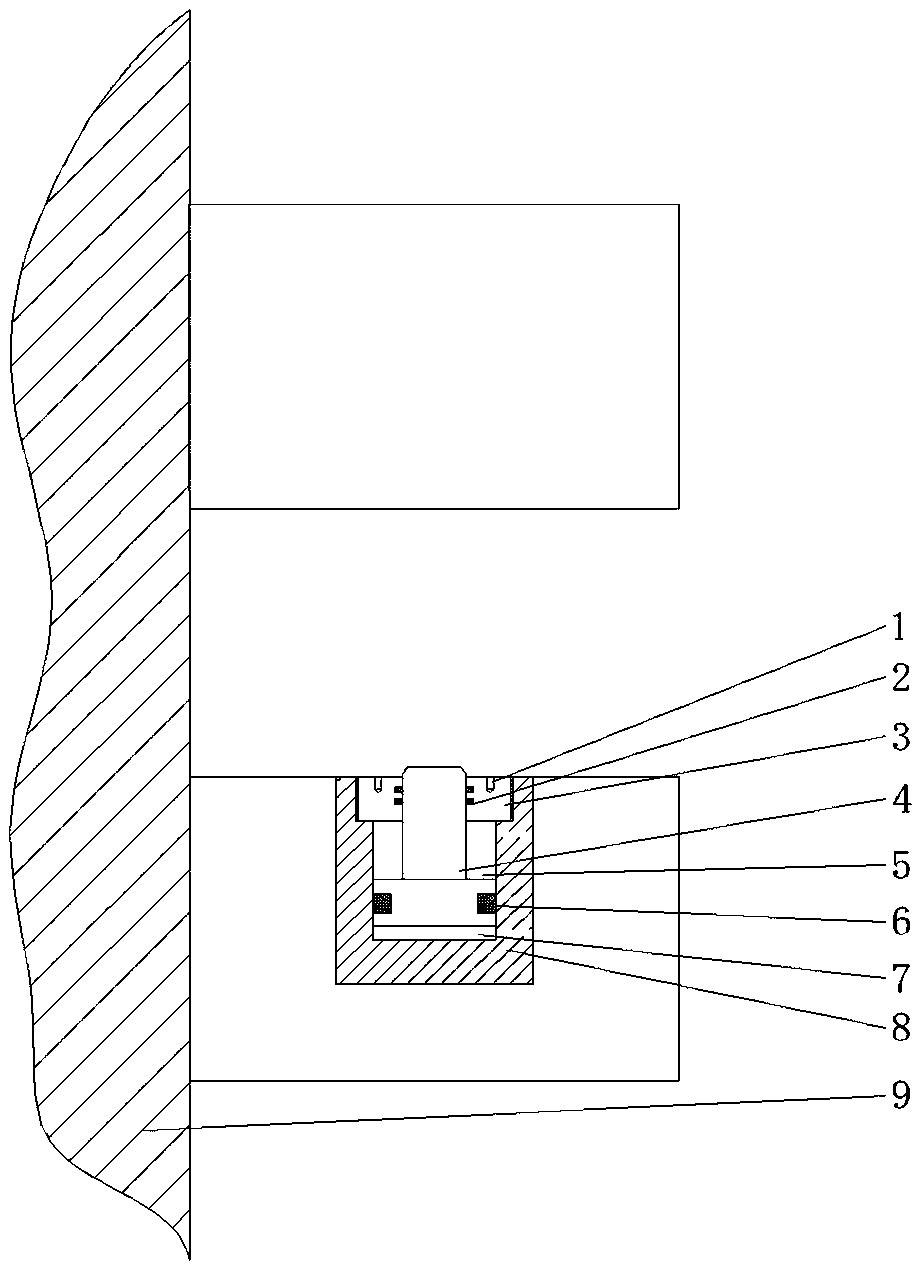

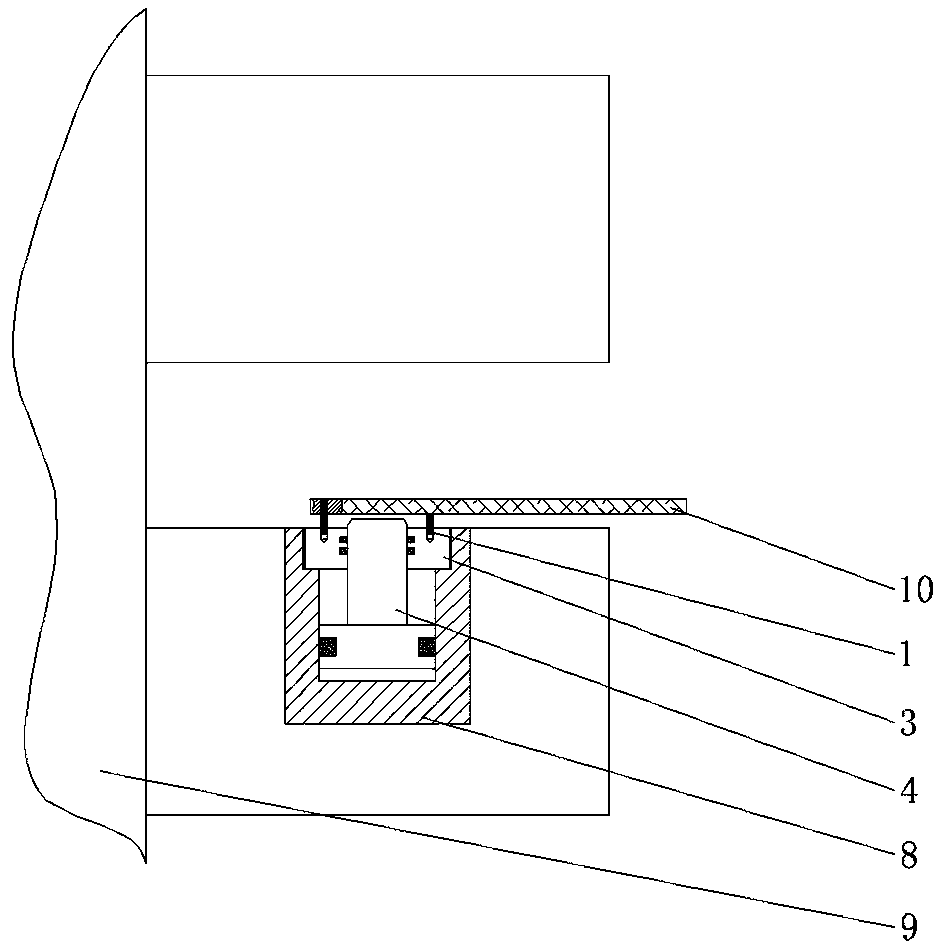

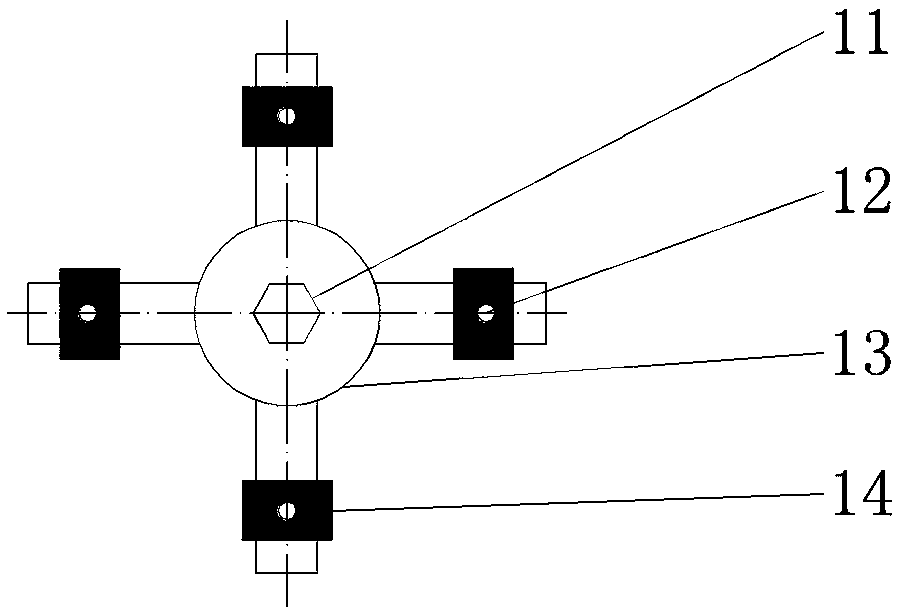

[0030] An auxiliary tool for quick disassembly and assembly of a bending cylinder, comprising: a tool bracket 13, two sliding blocks 14, two sliding blocks to fix the top wire 12, the middle part of the tool bracket 13 can be clamped on the end cover 3 of the bending cylinder, and the sliding block 14 can slide on the tool bracket 13, the lower end of the sliding block 14 is provided with a sliding block pin head 16, which is used to connect the disassembly hole 1 on the end cover of the bending roller cylinder, and the sliding block fixing jackscrew 12 is used to fix the sliding block on the tool On the support 13, the diameter of the sliding block pin head 16 is 5 millimeters.

Embodiment 2

[0032] An auxiliary tool for quick disassembly and assembly of a bending cylinder, comprising: a tool bracket 13, 4 sliding blocks 14, 4 sliding blocks to fix the top wire 12, the middle part of the tool bracket 13 can be clamped on the end cover 3 of the bending cylinder, and the sliding block 14 can slide on the tool bracket 13, the lower end of the sliding block 14 is provided with a sliding block pin head 16, which is used to connect the disassembly hole 1 on the end cover of the bending roller cylinder, and the sliding block fixing jackscrew 12 is used to fix the sliding block on the tool On the support 13, the diameter of the sliding block pin head 16 is 10 millimeters.

Embodiment 3

[0034] An auxiliary tool for quick disassembly and assembly of a bending cylinder, comprising: a tool bracket 13, 4 sliding blocks 14, 4 sliding blocks to fix the top wire 12, the middle part of the tool bracket 13 can be clamped on the end cover 3 of the bending cylinder, and the sliding block 14 can slide on the tool bracket 13, the lower end of the sliding block 14 is provided with a sliding block pin head 16, which is used to connect the disassembly hole 1 on the end cover of the bending roller cylinder, and the sliding block fixing jackscrew 12 is used to fix the sliding block on the tool On the support 13, the slide block pin head 16 has a diameter of 8 millimeters, and the tool support 13, slide block 14, slide block fixed top wire 12 and slide block pin head 16 are made of tool steel.

PUM

Login to view more

Login to view more Abstract

Description

Claims

Application Information

Login to view more

Login to view more - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap