Spiral rubber band position adjusting device

A technology for adjusting devices and rubber bands, which is applied in the directions of packaging, transportation and packaging, packaging/bundling items, etc. It can solve the problems that the bundling quality cannot be guaranteed, the effect of bundling completion is affected, and the actual requirements cannot be met, and the floor space is small. , reduced distortion, and easy operation

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0020] Specific examples of the present invention are given below. The specific embodiments are only used to further describe the present invention in detail, and do not limit the protection scope of the claims of the present application.

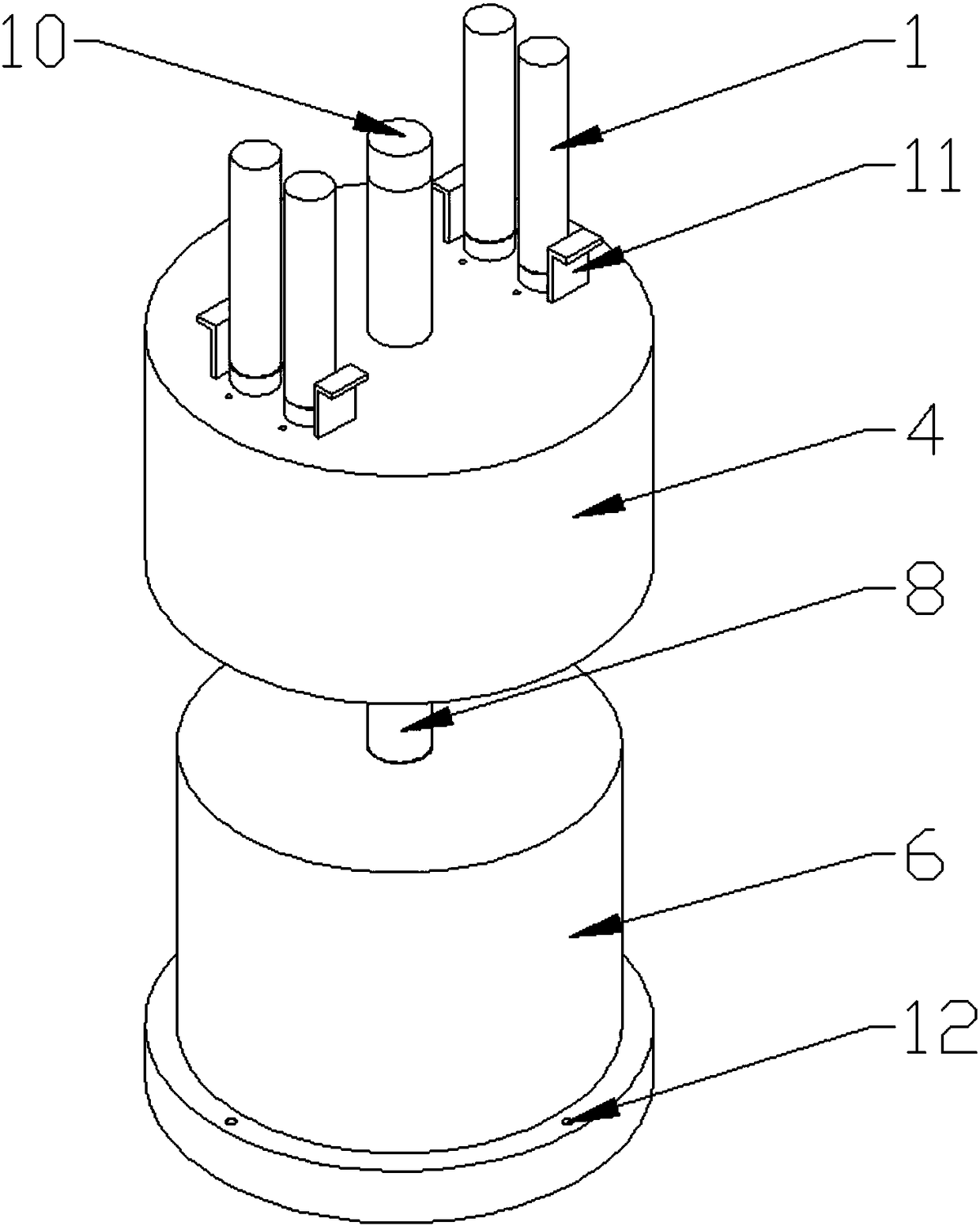

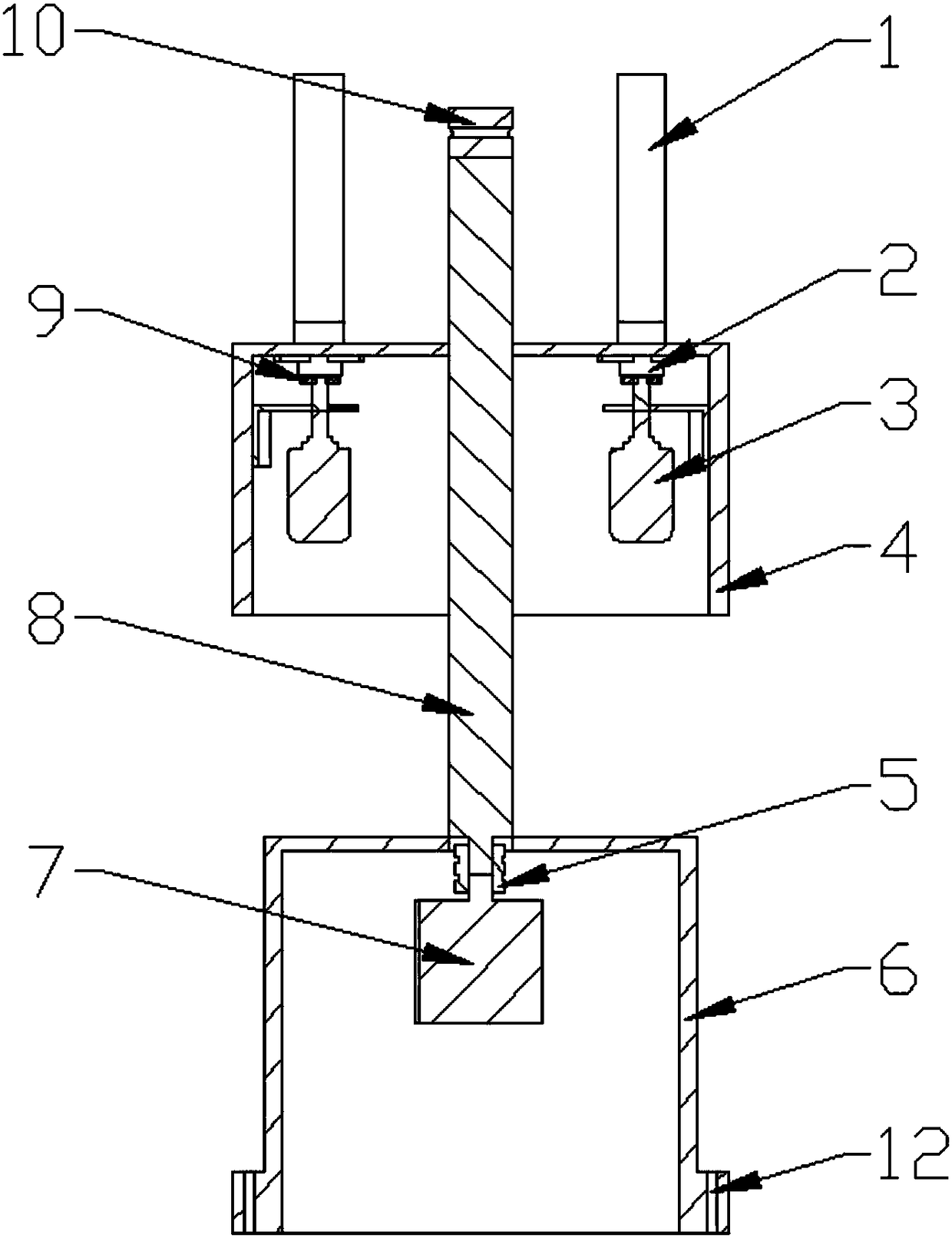

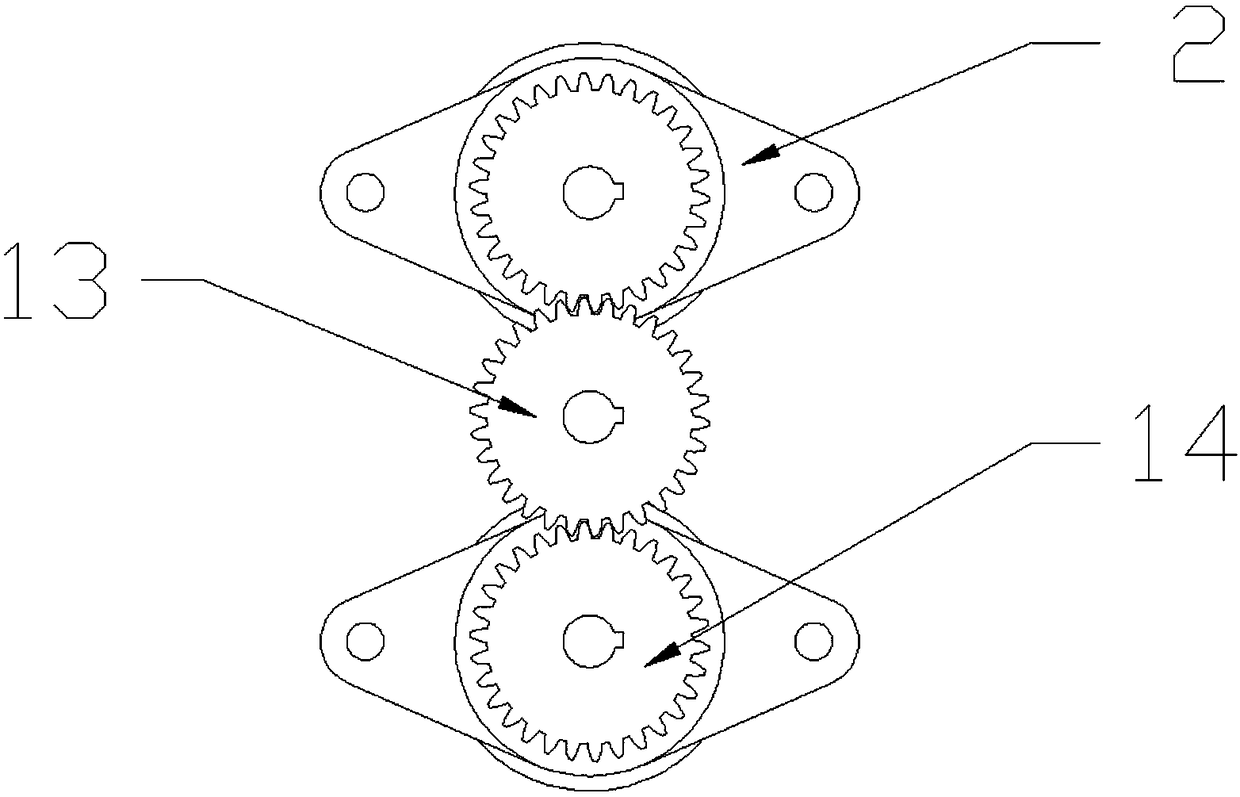

[0021] The invention provides a screw type rubber band position adjustment device (see Figure 1-3 , referred to as the device), is characterized in that the device includes a number of screw sets, a number of bearings 2, a number of motors 3, a rotating disc 4, a coupling 5, a base 6, a 180 ° rotating cylinder 7 , a rotating shaft 8, several transmission gear sets 9, a detection infrared sensor 10 and several limit stop irons 11; each transmission gear set 9 includes an intermediate transmission gear 13 and two side transmission gears 14; each helical wire The rod group includes two screw screws 1 arranged side by side in the same direction of rotation;

[0022] The bottom of the base 6 is provided with anchor bolt holes 12, which are us...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com