Automatic ink adding mechanism and ink adding method thereof

A technology of automatic inking and ink filling, applied in printing presses, general parts of printing machinery, printing, etc., can solve the problems that printing presses cannot meet the development needs of enterprises, easily soil other parts, damage parts, etc., to prevent The effect of pollution, smooth operation and improved efficiency

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

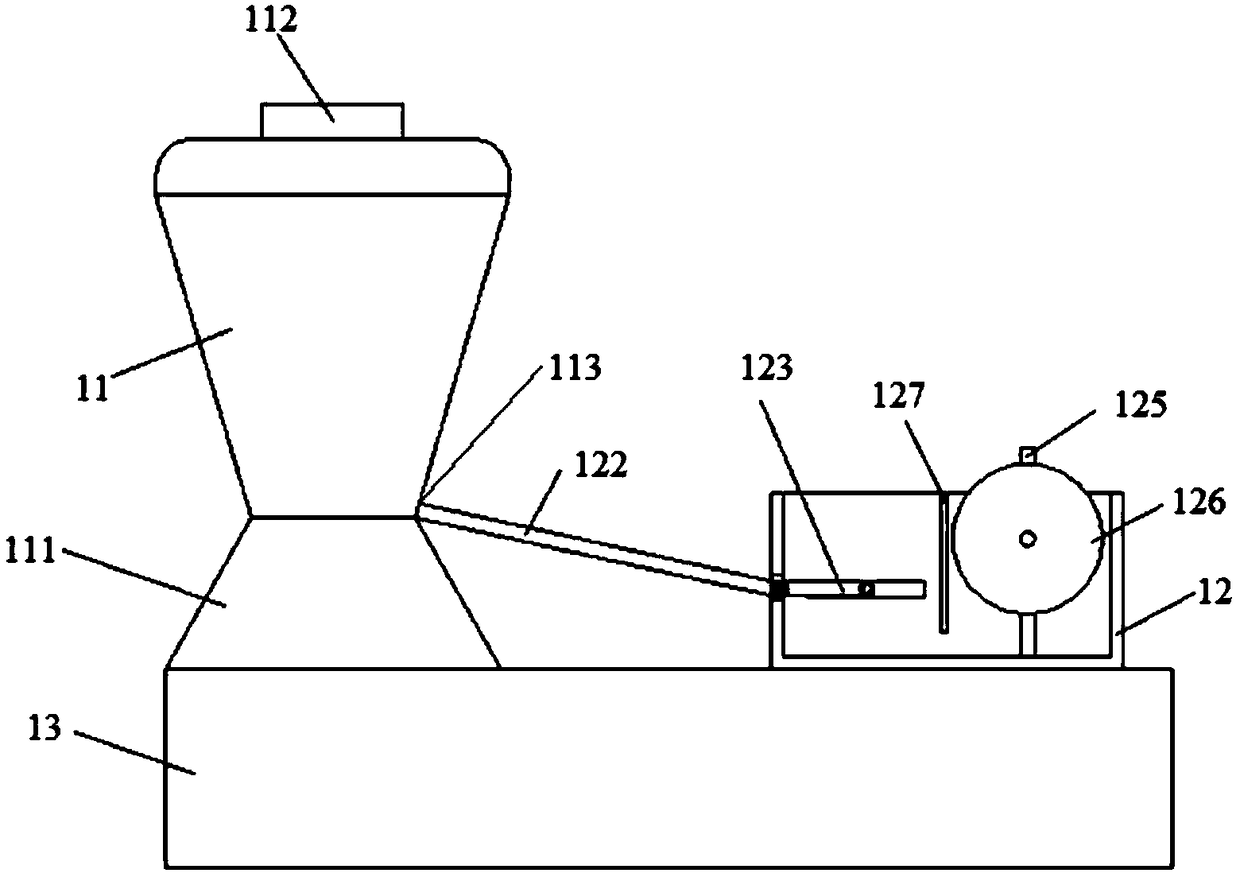

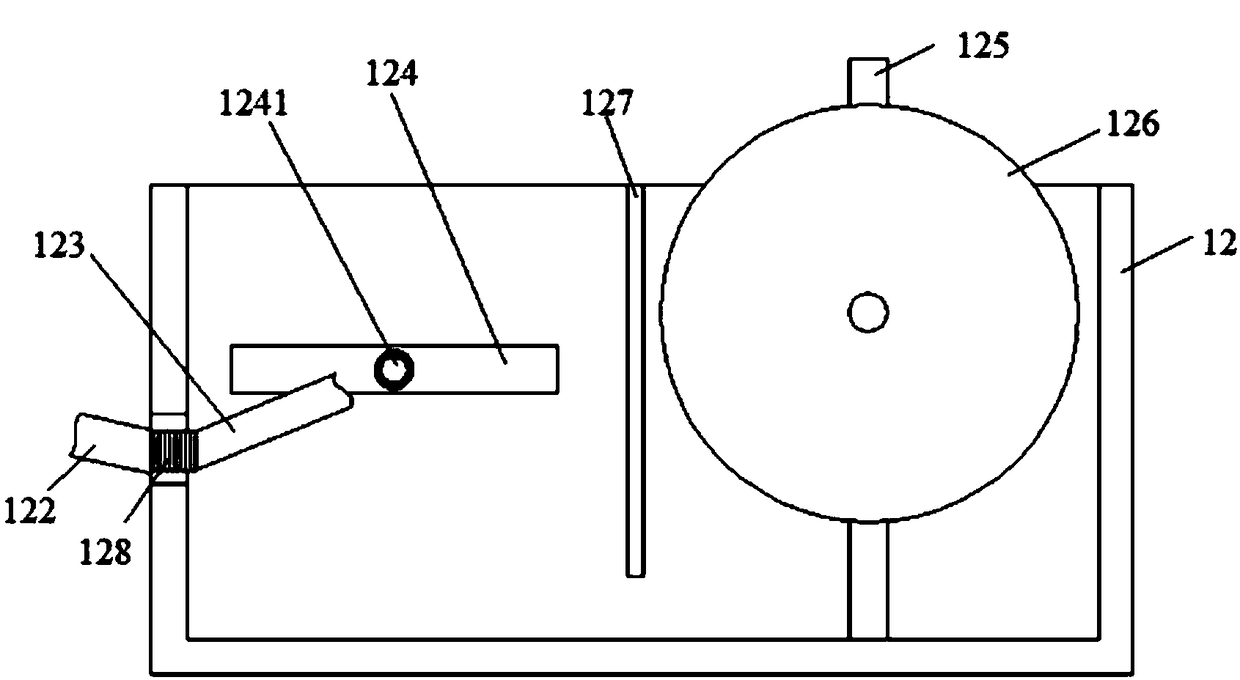

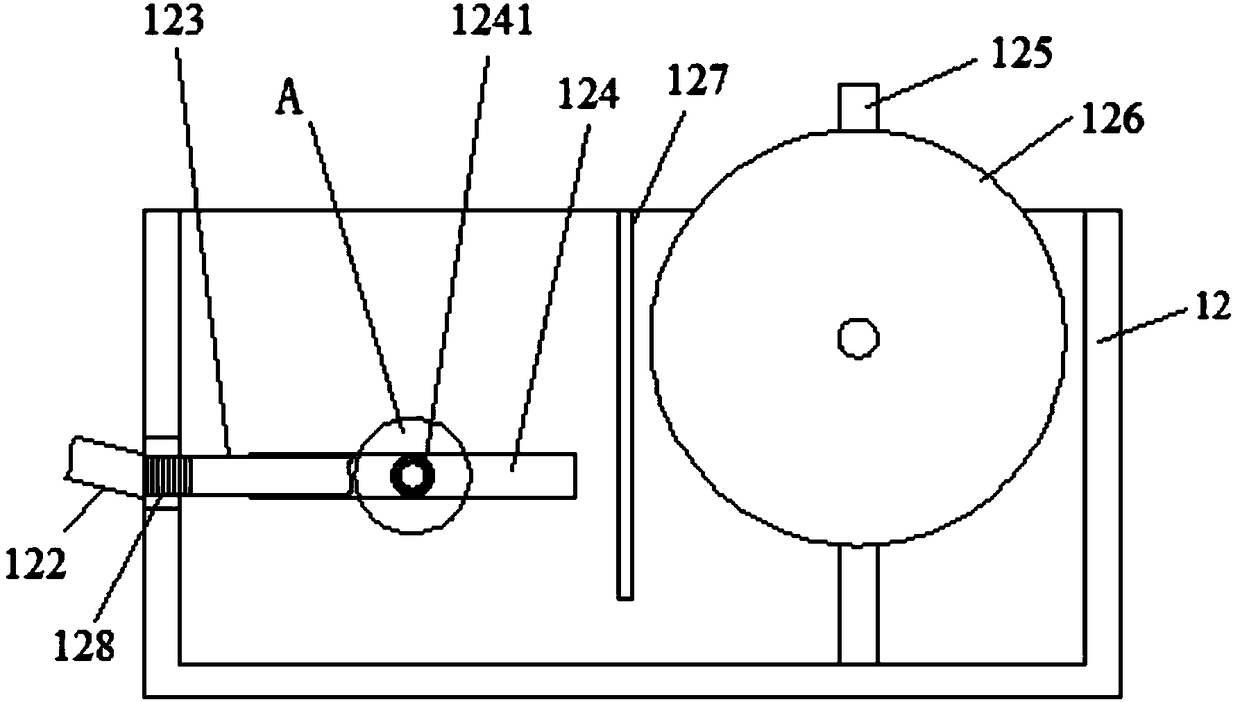

[0031] see figure 1 and figure 2 , the present invention provides a technical solution: an automatic ink filling mechanism, including an ink barrel 11, an ink cartridge 12 and a base 13, the ink barrel 11 is installed on the base 13 through the mounting seat 111, and the ink cartridge 12 is also installed on the base 13; The side wall of the ink cartridge 12 is provided with a through hole 121, and the ink barrel 11 is provided with a first ink outlet 113, and the first ink outlet 113 communicates with an end of the rotating conduit 123 through the ink conduit 122, and the ink conduit 122 is connected to the rotating conduit 123. The pipeline formed by the rotating conduit 123 passes through the above-mentioned through hole 121 . A sleeve 1231 is installed on the other end of the rotating conduit 123, and a second ink outlet slot 12311 is provided on the inner wall of the sleeve 1231; a buoyancy plate 124 is arranged in the ink cartridge 12, and the buoyancy plate 124 is fix...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com