A forming device for extrusion forming of cartons

An extrusion forming and carton technology, which is applied in the field of forming devices for carton extrusion forming, can solve the problems of non-adjustment and single adaptability of equipment/components/components

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

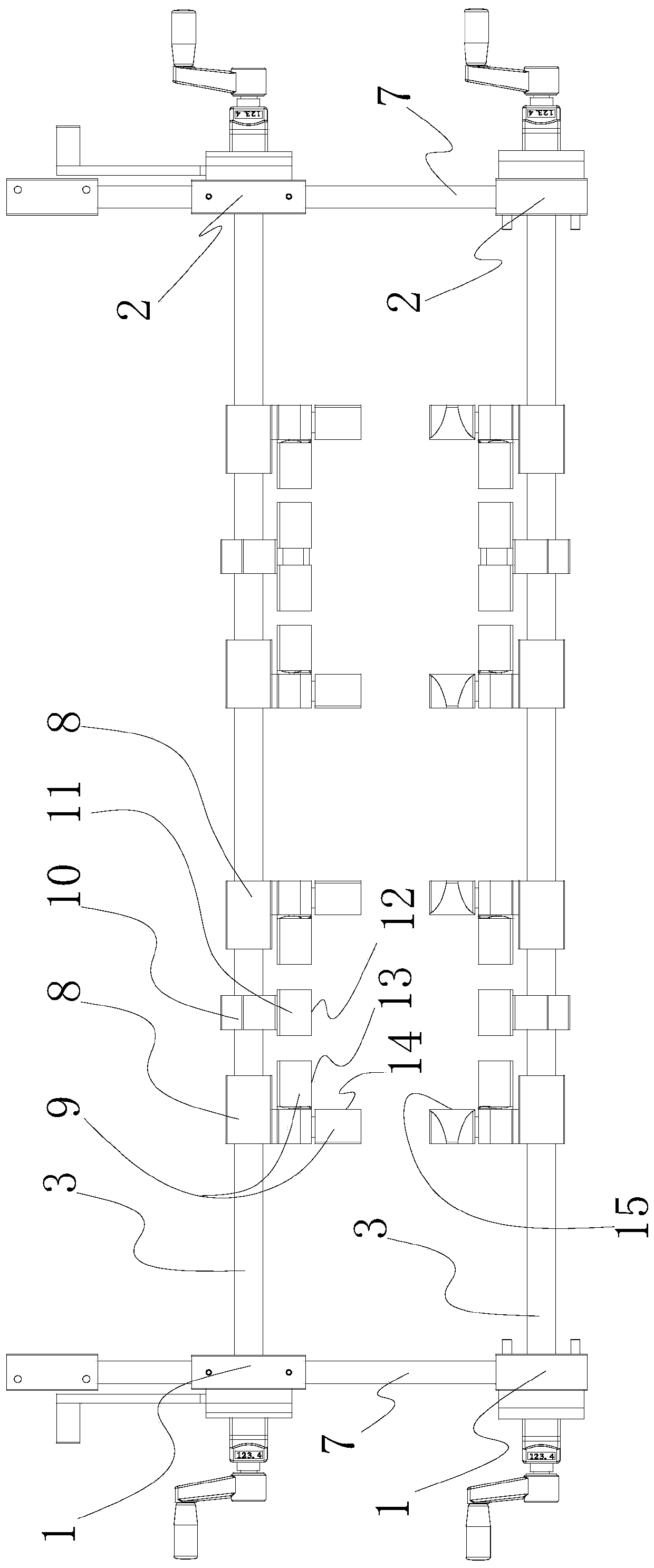

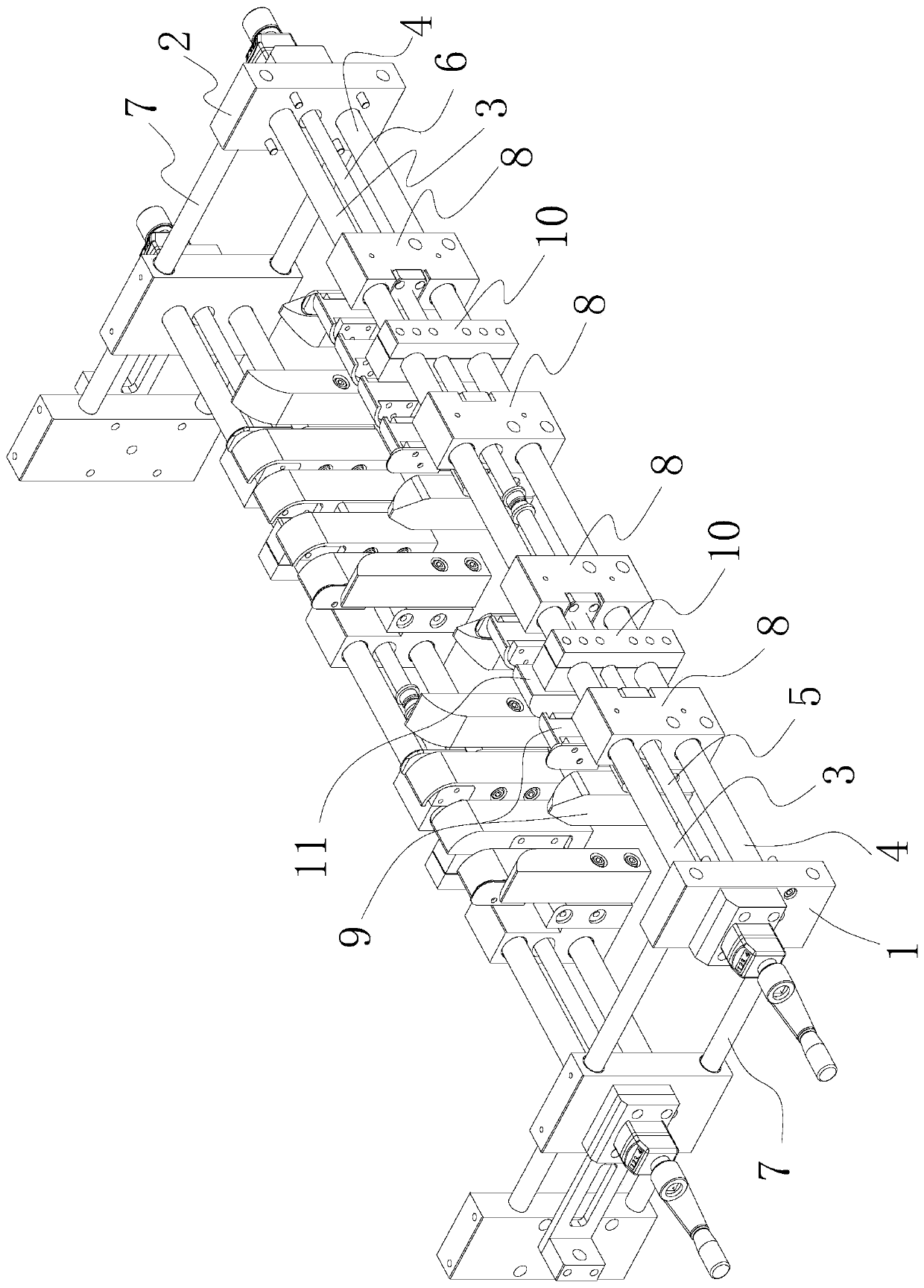

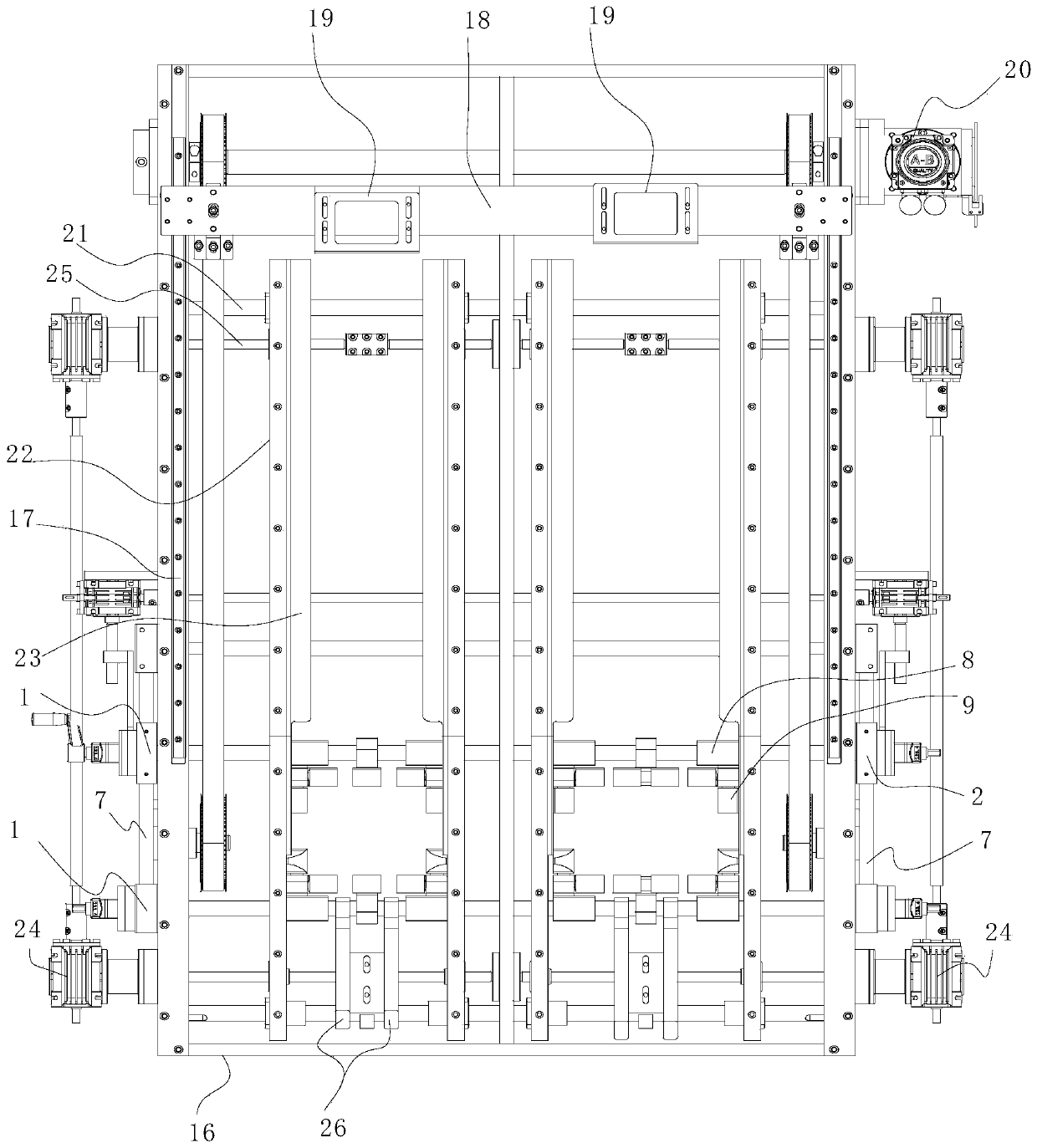

[0029] Such as figure 1 , 2 , 3, and 4 show the first embodiment of the present invention.

[0030] The forming device for extrusion forming of a carton includes a forming die and a conveying part.

[0031] The conveying parts include the installation frame II16 and the linear translation feeding assembly. The installation frame II16 is a frame structure, which is formed by connecting four rectangular metal plates end to end.

[0032] The linear translation feeding assembly is installed on the installation frame Ⅱ16. The linear translation feeding component includes a translation component, an object-carrying component I, and an object-carrying component II.

[0033] The translation assembly includes a power unit I20, a synchronous belt drive unit, a power output unit and a push plate 19. The power unit I20 includes a servo motor and a reducer. The synchronous belt transmission unit includes a rotating shaft, four synchronous pulleys, and two synchronous belts. The rota...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com