Dual-scale dynamic homogenizing system for flow field

A dual-scale and dynamic technology, applied in chemical instruments and methods, gas treatment, membrane technology, etc., can solve problems such as insufficient gas phase rectification, inability to affect gas phase distribution, and large system resistance, so as to achieve short renovation period and full scale The effect of regulating and reducing consumption

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

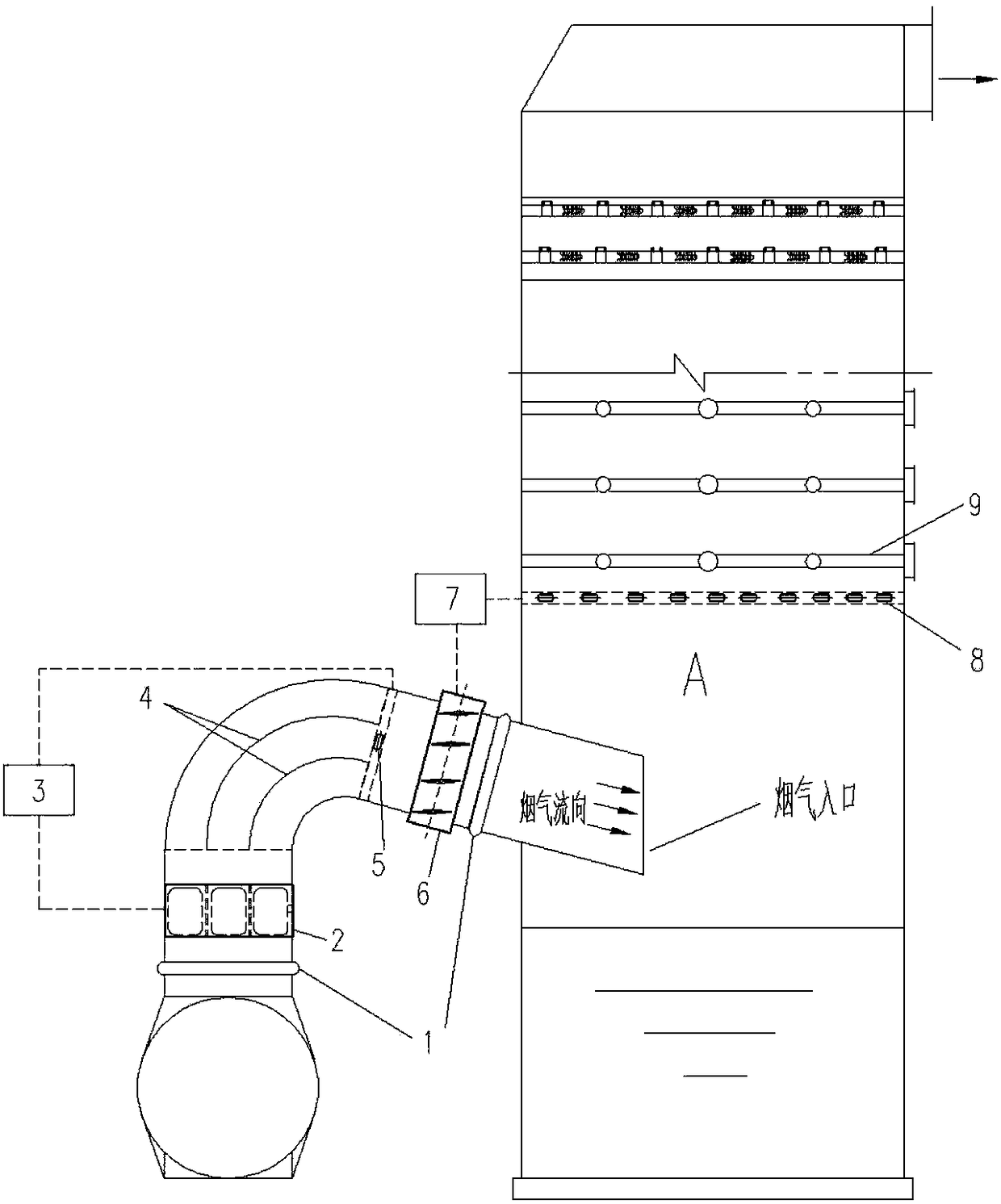

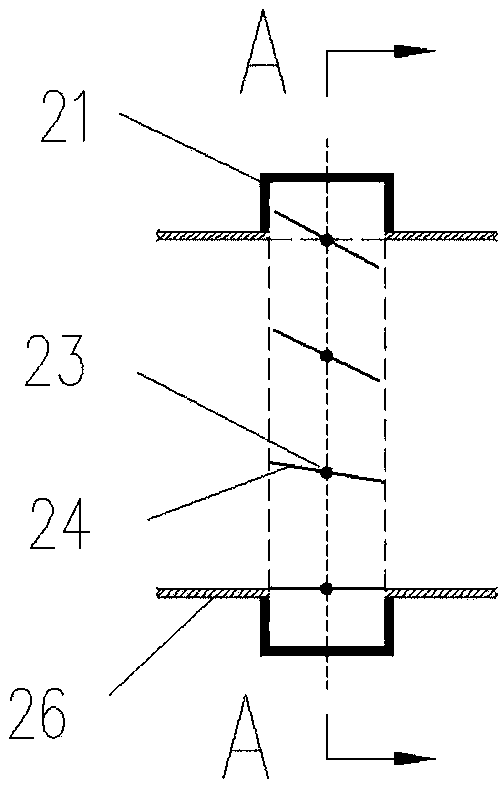

[0030] In this case, for example figure 1 , figure 2 As shown, the flow field dual-scale dynamic homogenization system of the present invention includes horizontal and vertical dynamic rectification components and a fixed flow guide unit, wherein both the horizontal and vertical dynamic rectification components include a flow field adjustment unit and a feedback control unit. Among them, the transverse flow field adjustment unit 2 is set in the straight flue section B, the fixed flow guide unit 4 is set in the turning flue section C, and the longitudinal flow field adjustment unit 6 is set in the connecting flue section D in front of the tower. Since the large aspect ratio of the rectangular flue in front of the absorption tower will aggravate the inhomogeneity of the transverse dimension of the flow field, the transverse flow field adjustment unit 2 is set upstream to ensure a longer homogenization time. The fixed flow guide unit 4 is used to assist the diversion of the flu...

Embodiment 2

[0040] In this example, the length of the connecting flue D in front of the tower is more than four times the nominal diameter of the flue, no fixed flow guide unit is installed, and the transverse flow field adjustment unit is installed on the connecting flue in front of the tower, located at the side of the longitudinal flow field adjustment unit upstream. All the other settings are the same as in Embodiment 1. The flue gas enters the absorption tower A after passing through the transverse flow field adjustment unit and the longitudinal flow field adjustment unit in turn.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com