Small-hole-opening extra-high-water-head integral-casting plane operating gate with fixed wheel

A technology of integral casting and high water head, which is applied in water conservancy projects, sea area projects, coastline protection, etc., and can solve problems such as arc door hinges are vulnerable to water flow impact, P-type water seal has a large pre-compression amount, and it is not suitable to arrange arc gates. , to achieve the effects of good fluidity, quality assurance, and reduced manufacturing difficulty

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

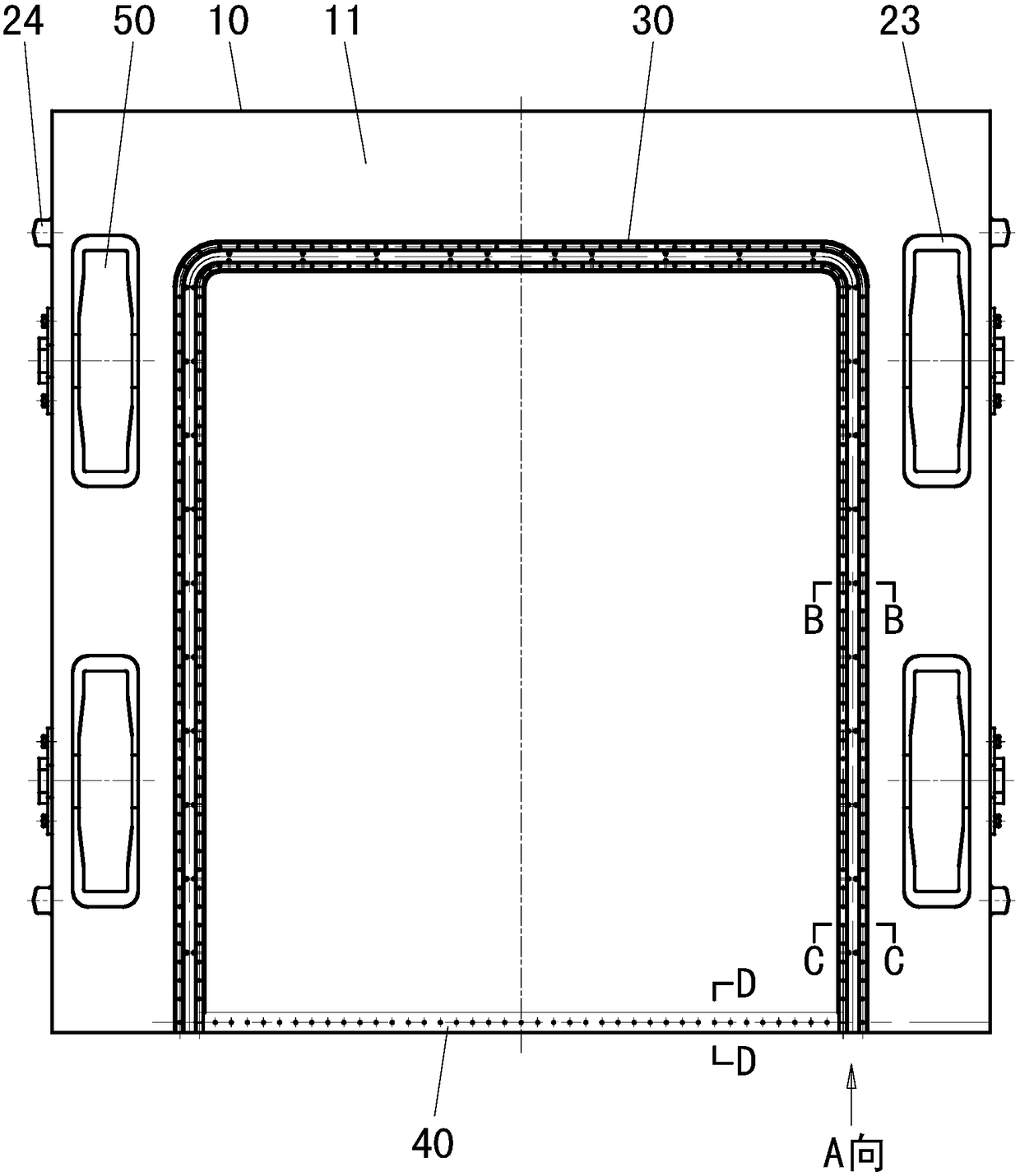

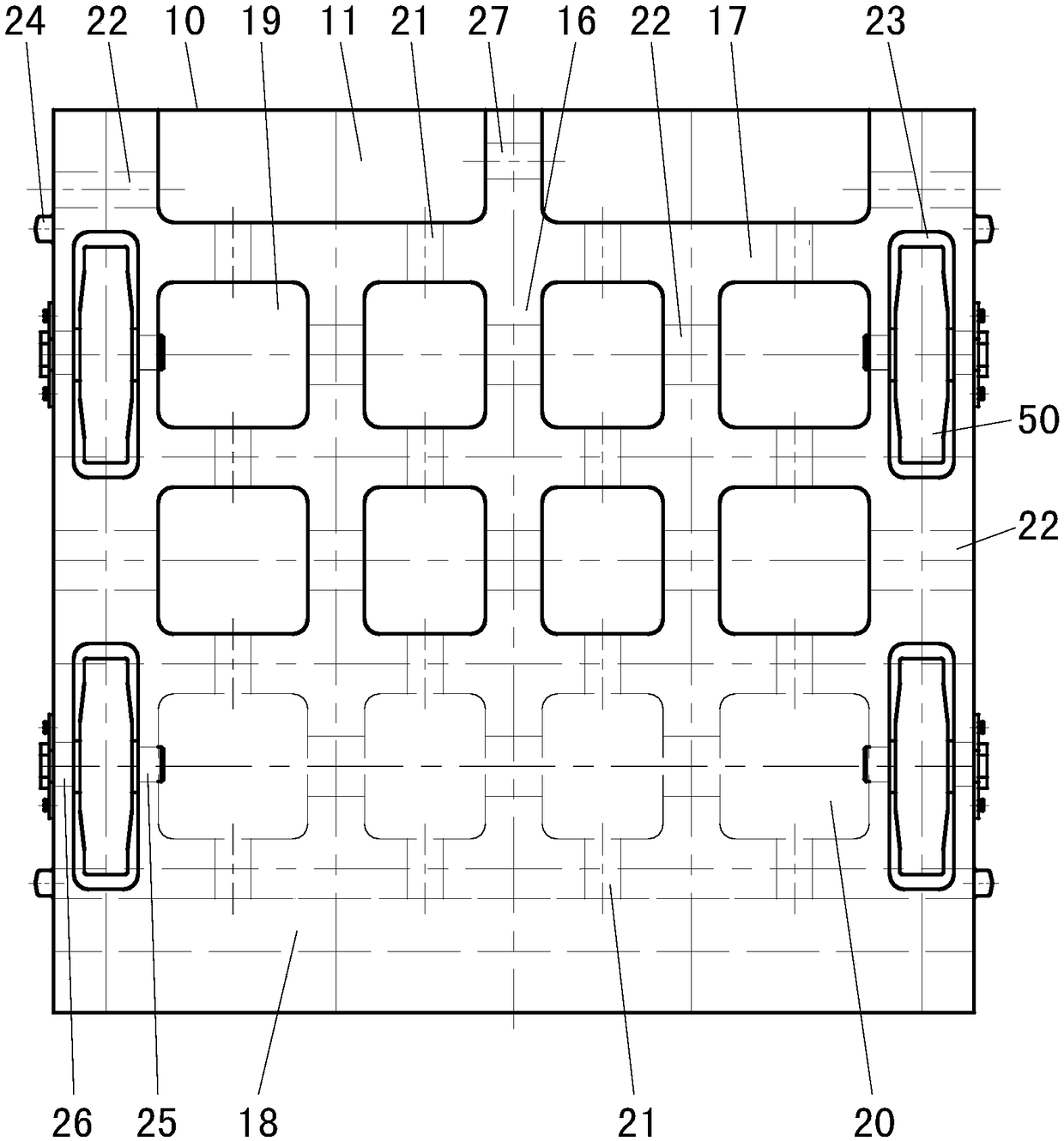

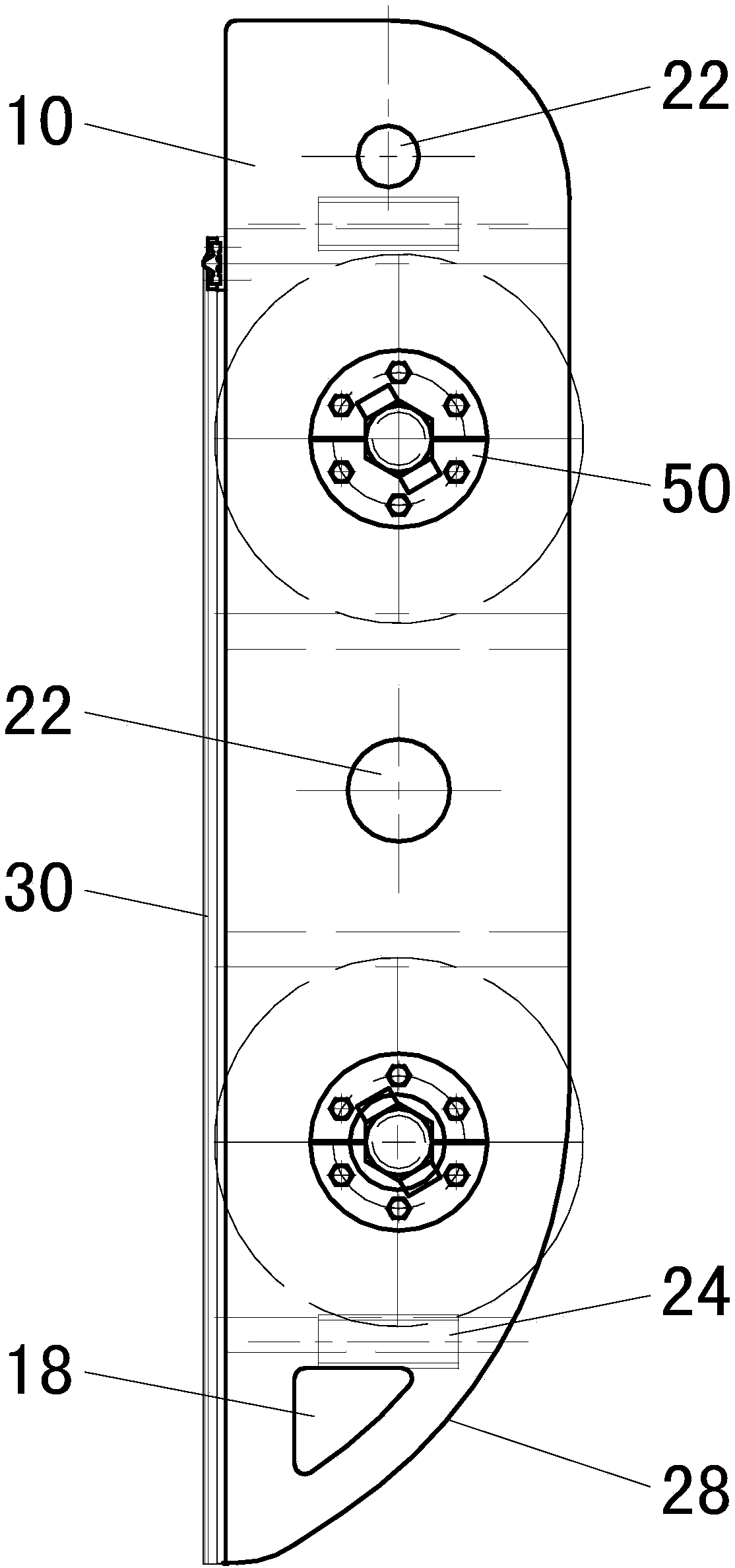

[0036] In this example, the working gate of the small orifice and extra-high water head integrally cast plane fixed wheel is as follows: Figure 1~3 As shown, the cast door body is formed by one casting. The cast door body 10 is cast with a top side water seal mounting seat 12, a bottom water seal mounting groove 15, a longitudinal beam 16, a beam 17, a triangular through hole 18, an open cavity 19, a closed cavity 20, and a longitudinal diversion hole 21. Structures such as lateral diversion holes 22, fixed wheel mounting holes 23, lateral sliders 24, and hanging holes 27.

[0037] Such as figure 2 As shown, the longitudinal beams 16 on both sides of the cast door body 10 are used as side beams, and the upper and lower parts on both sides of the side beams are centered and symmetrically provided with two fixed wheel mounting holes 23; the interior of the fixed wheel mounting holes 23 is rounded; as Figure 8 As shown, the fixed wheel mounting hole 23 is provided with a fix...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com