Automatic meat hammering machine imitating handwork

An automatic hammer, imitating manual technology, applied in the direction of meat processing, meat tenderization, meat softening by beating, etc., can solve the problem of meat tissue damage, achieve better taste and save manpower

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

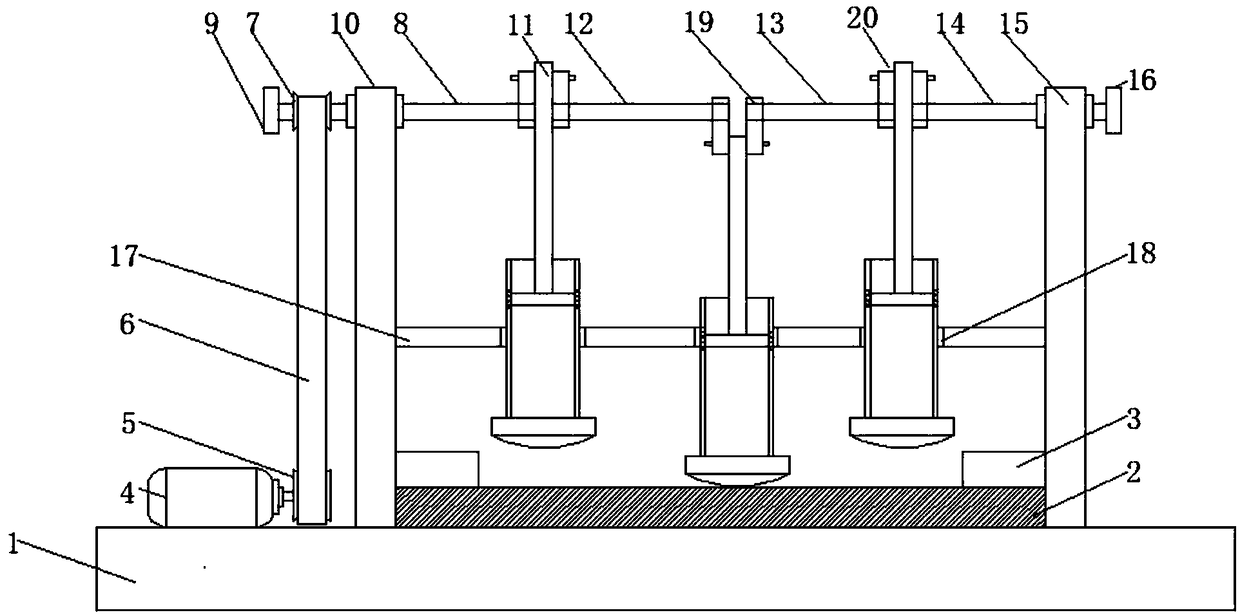

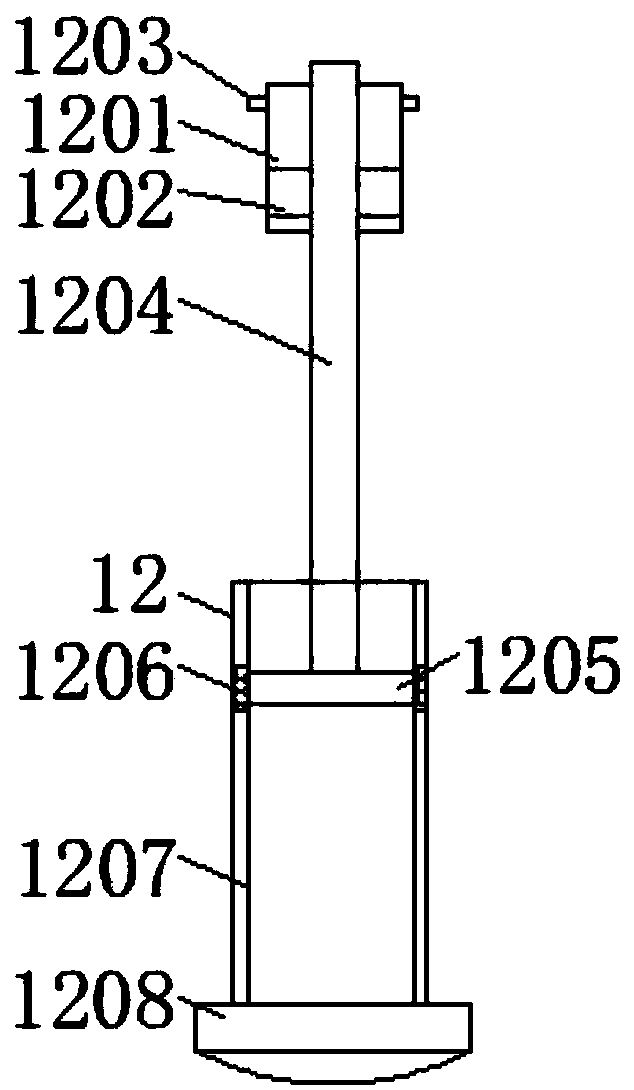

[0021] Such as Figure 1-2 As shown, the present invention provides a technical solution: a manual imitation automatic meat hammering machine, comprising a bottom plate 1, the top of the bottom plate 1 is fixedly connected with a placement plate 2, and both sides of the top of the placement plate 2 are fixedly connected with pushers. The meat piece 3 is fixedly connected with the first support rod 10 and the second support rod 15 on both sides of the top of the bottom plate 1 respectively, and the opposite sides of the two push meat pieces 3 are connected with the first support rod 10 and the second support rod 15 respectively. The bottom on the opposite side is fixedly connected, and the left and right sides of the placement plate 2 are respectively fixedly connected to the bottom of the opposite side of the first support bar 10 and the second support bar 15. Since the placement plate 2 is improved, it is applied to the placement The two sides of the top of the plate 2 are fi...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com