Straw pulverizer

A technology of straw shredders and racks, which is applied to harvesters, agricultural machinery and implements, cutters, etc., can solve the problems of increasing hammer claw wear and power consumption, and achieves the effect of high crushing rate and good stubble removal rate

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

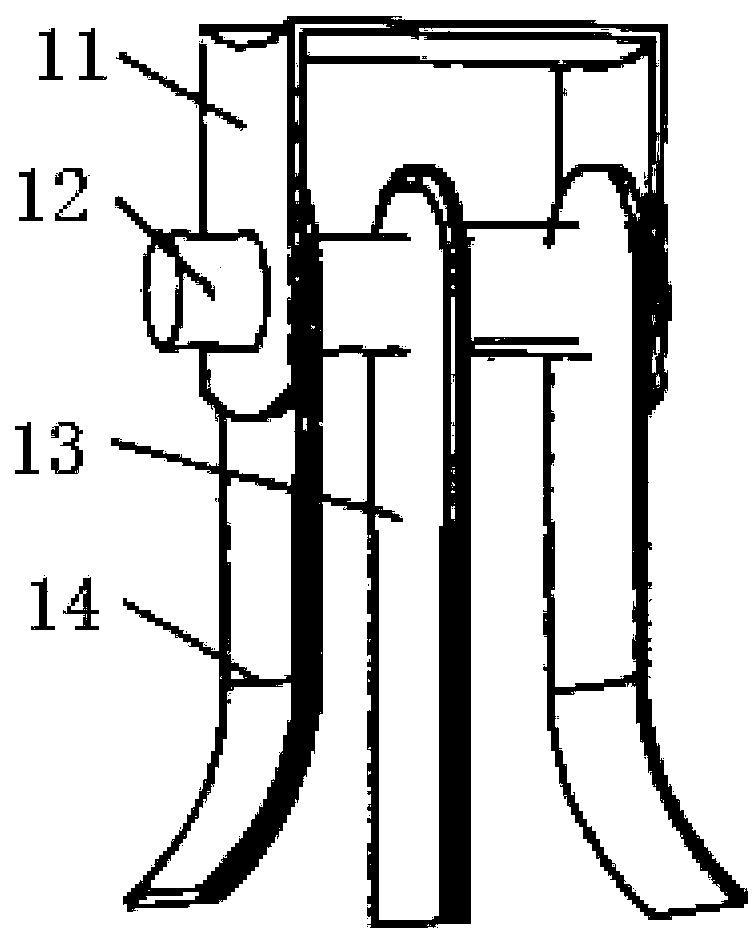

[0015] Example 1, see figure 1 , the straw grinder of the present invention comprises a frame 1, an engine 2, a gearbox 3, a main shaft 4, a saw disc cutter shaft 5, a saw blade 6, a knife shaft 7, a knife 8 and a suspension device 9, and the frame 1 consists of The base plate, the cover plate, the left side plate and the right side plate are enclosed, the left side plate is provided with the left mounting hole of the saw disc cutter shaft and the left mounting hole of the swing knife shaft, and the right side plate is provided with the saw disc cutter shaft The right mounting hole, the right mounting hole of the knife shaft and the main shaft mounting hole, the engine mounting groove is arranged on the bottom plate of the frame 1, the engine 2 is installed in the engine mounting groove, the output shaft of the engine 2 is connected with the main shaft 4 through the gearbox 3, The other end of the main shaft 4 extends out of the main shaft installation hole, one end of the saw...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com