Multi-wavelength laser damage testing and analysis system for optical components

A technology of laser damage and optical components, which is applied in the direction of testing optical performance, etc., and can solve problems such as unseen

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0041] The present invention will be further described below in conjunction with the embodiments and drawings, but the protection scope of the present invention should not be limited by this.

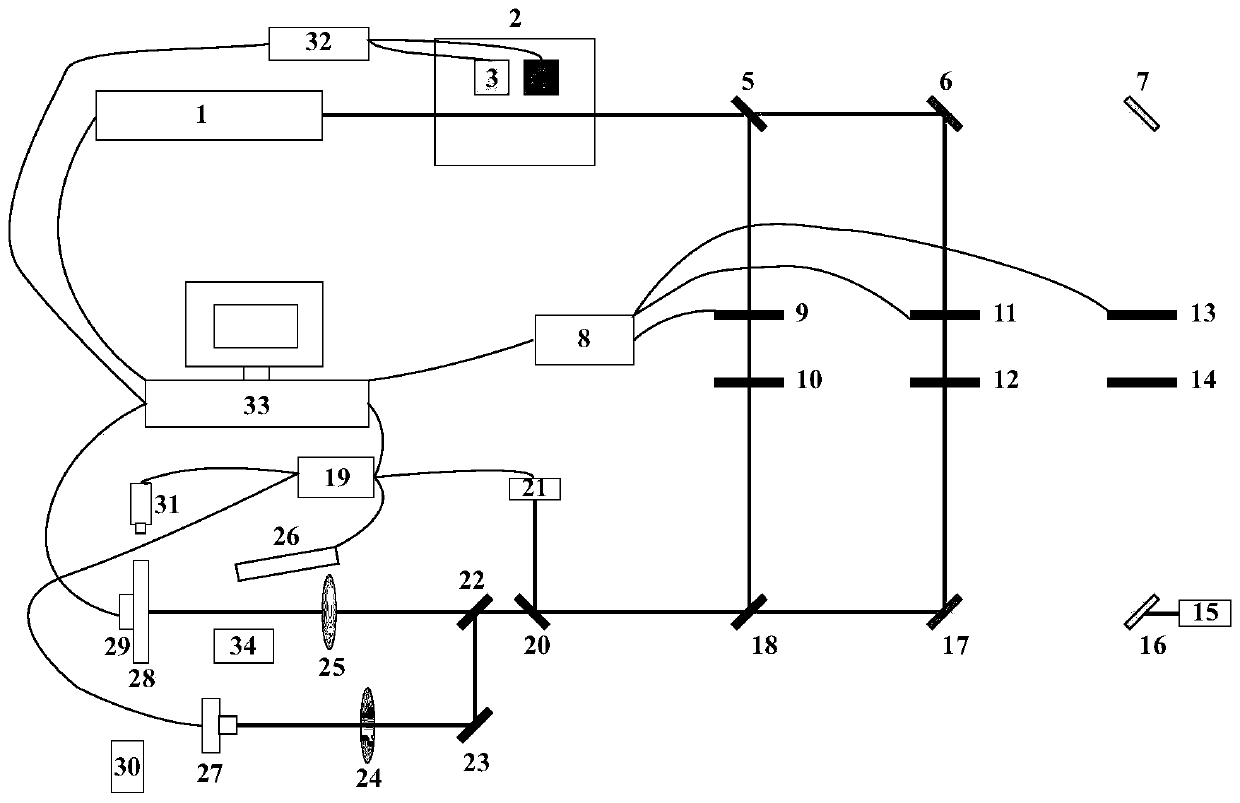

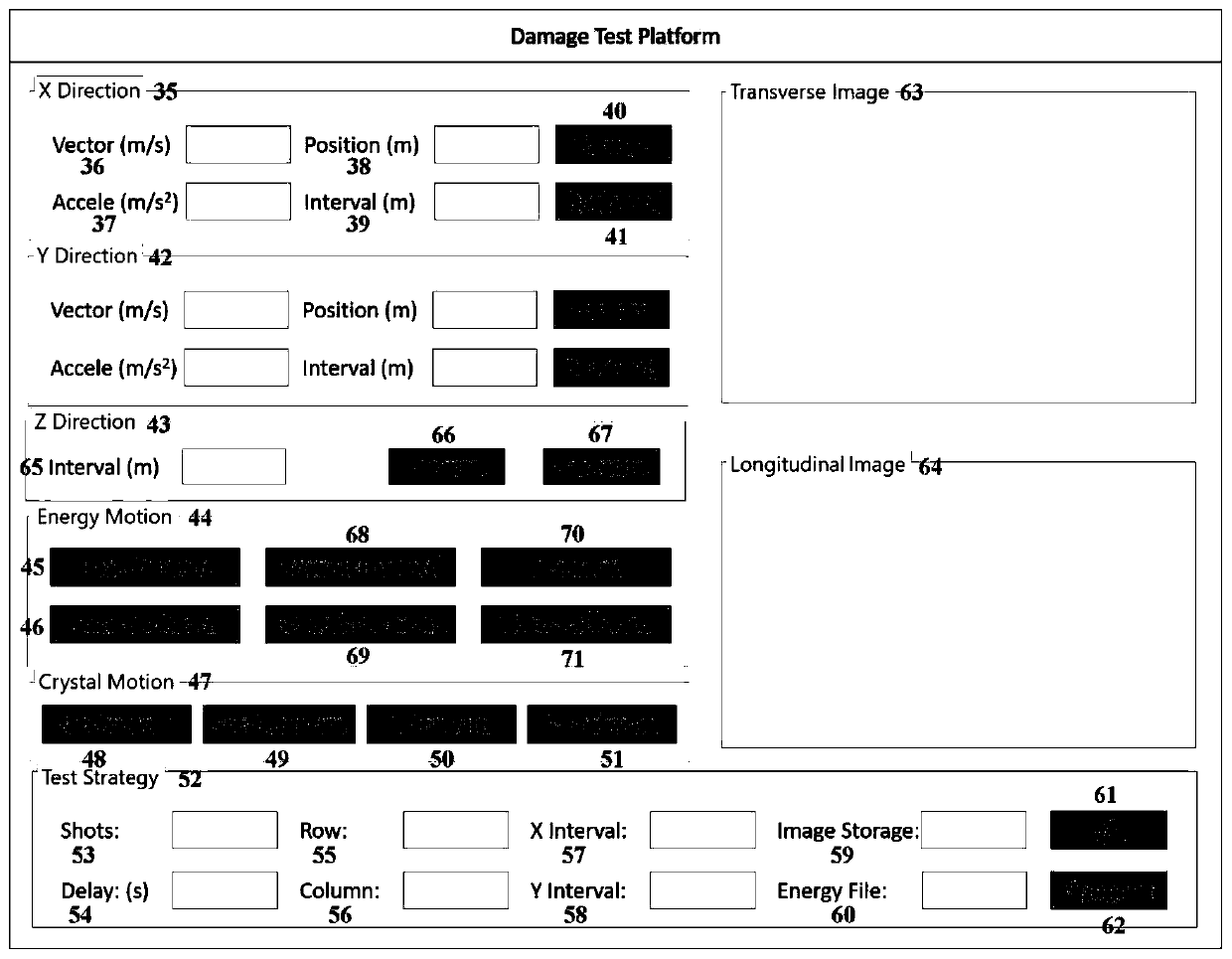

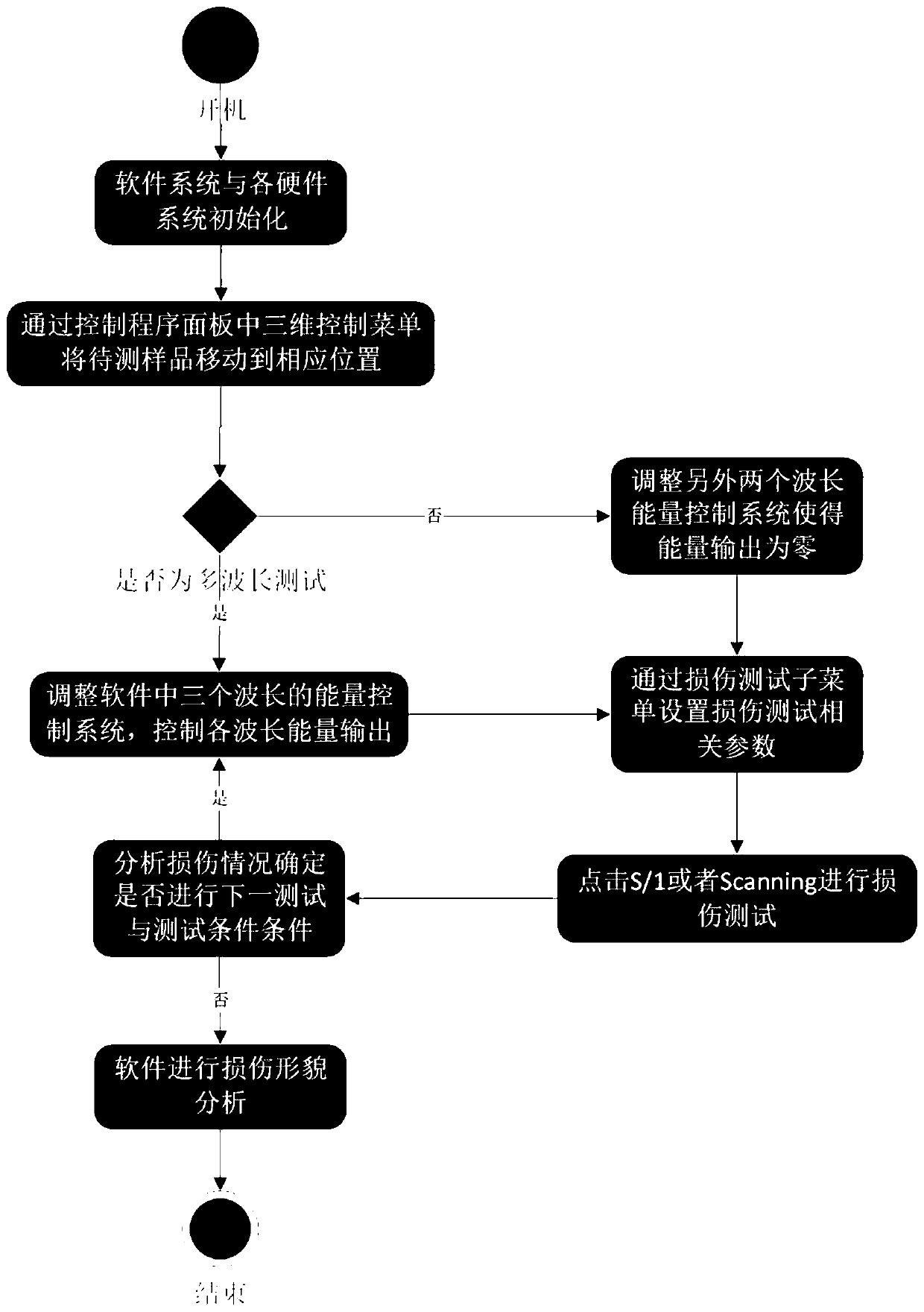

[0042] figure 1 It is a schematic diagram of the optical element multi-wavelength laser damage test and analysis system of the present invention. figure 1 It can be seen that the multi-wavelength laser damage test and analysis system of the optical element of the present invention is composed of a pulsed laser 1. The laser light output by the pulsed laser 1 passes through the double frequency crystal 3 and the frequency triple crystal 4 in the frequency doubler drying box 2 in sequence. A mixed pulse laser with three wavelengths of fundamental frequency, frequency doubled and frequency tripled is formed. Along the direction of the pulsed laser, there are the first beam splitter 5, the first double frequency high-reflective mirror 6 and the third beam splitter 7 in sequence. The output direc...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com