An isolation seat applied to tap terminals of dry-type transformers

A dry-type transformer and terminal technology, which is applied in the field of transformers, can solve the problems of insufficient distance, increased manufacturing cost, increased creepage distance, etc., and achieves the effects of saving cost, improving utilization rate, and simple structure

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

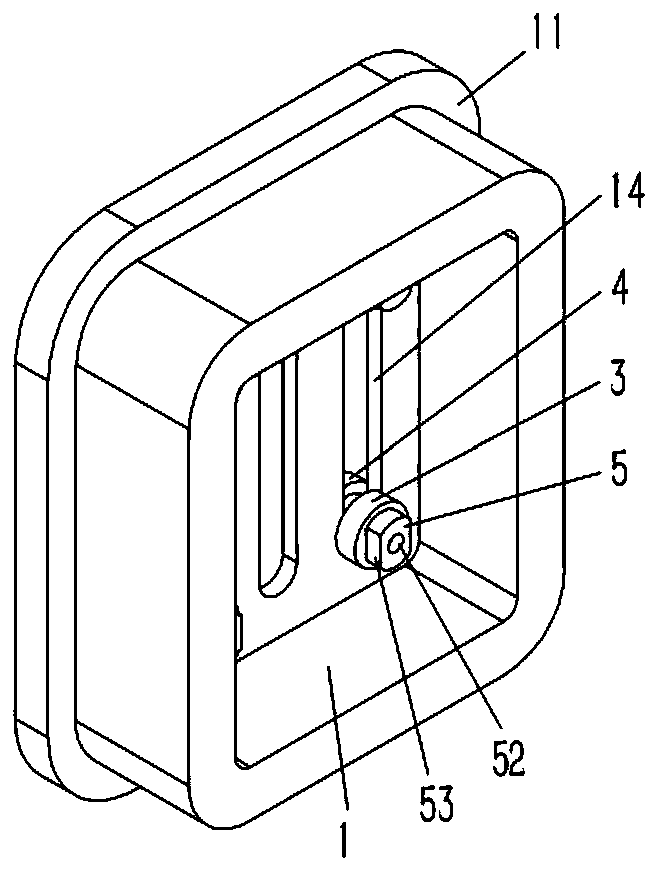

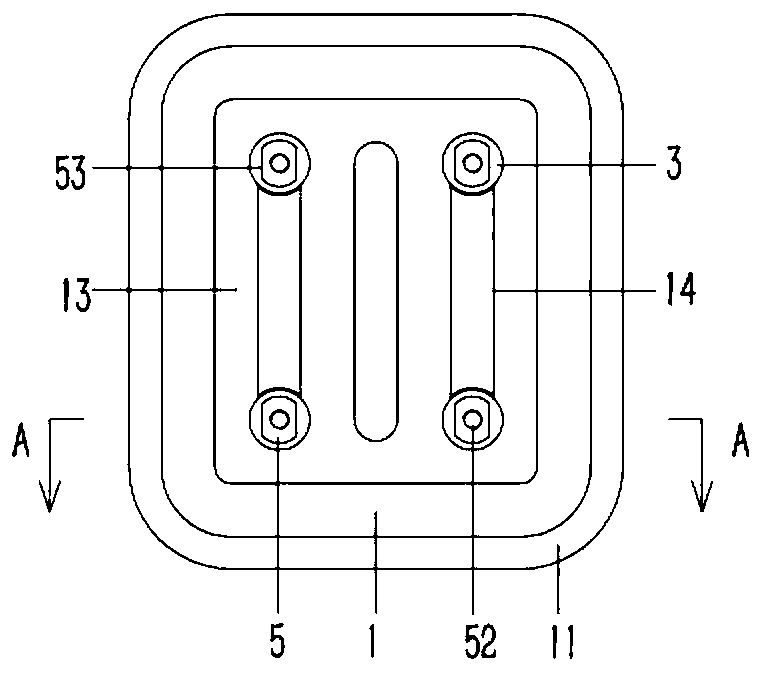

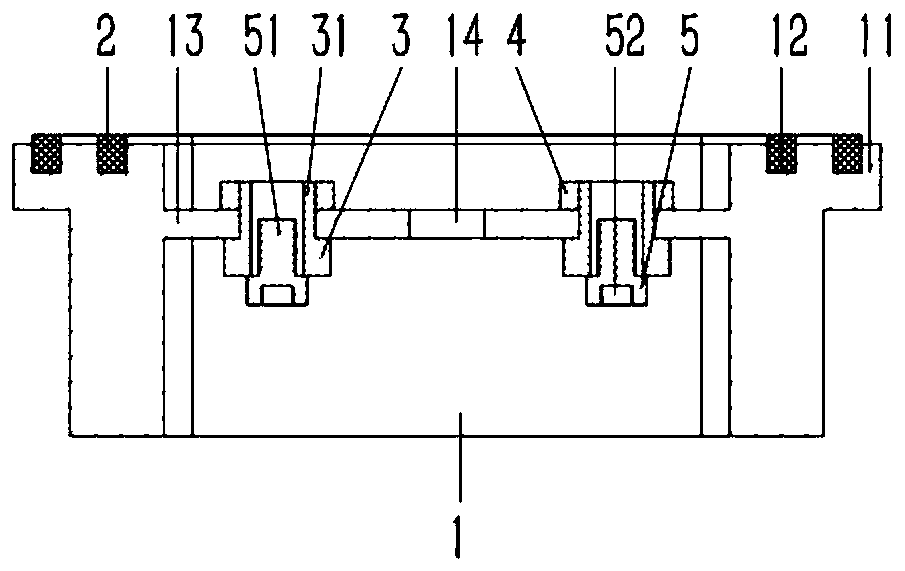

[0021] Example: see Figures 1 to 3 As shown, an isolation seat applied to tap terminals of dry-type transformers includes a "back"-shaped ceramic base body 1, the lower end of the ceramic base body 1 has a flange 11, and several grooves are formed on the bottom surface of the flange 11. A "back"-shaped groove 12, a sealing ring 2 is inserted and fixed in the groove 12 of the ceramic base 1, and a limiting plate 13 is formed on the inner side of the ceramic base 1, and several longitudinal guides are formed on the limiting plate 13 Groove 14, the front end surface of the limiting plate 13 leans against the positioning sleeve 3, the rear end surface of the positioning sleeve 3 is formed with a connecting sleeve 31, and the connecting sleeve 31 passes through the guide groove 14 of the limiting plate 13 to insert and fix the limiting sleeve 4. The front side of the limiting sleeve 4 is provided with a stop plate 5, a stud 51 matching the transformer tap terminal is formed on the...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com