Comprehensive practical teaching system of intelligent manufacturing technology

A practical teaching and intelligent manufacturing technology, applied in the field of comprehensive practical teaching system, can solve problems such as poor teaching effect, waste of resources, and no mature technology found, and achieve the effect of improving teaching effect, meeting functional requirements, and having production characteristics.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

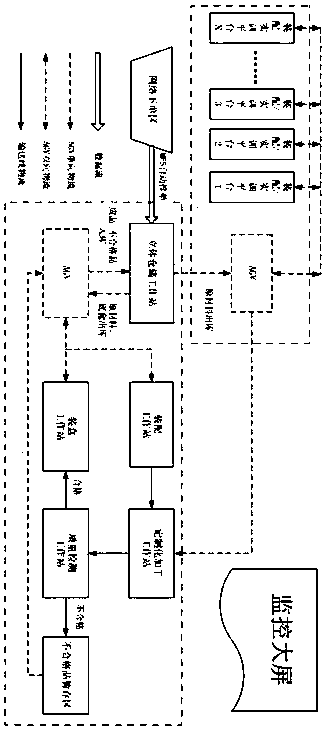

[0051] The present invention provides a comprehensive practice teaching system of intelligent manufacturing technology, such as figure 1 As shown, the comprehensive practice teaching system of the intelligent manufacturing technology includes a preparation institution, a practice teaching institution and a system monitoring institution;

[0052] Among them, the preparation institution has an online ordering area, which includes all-in-one machines, PCs, tablet computers, mobile phones and other terminal devices, and new production objects can be created through on-site all-in-one machines, PCs, tablet computers, mobile phones and other terminal devices Order;

[0053] Practical teaching institutions include three-dimensional storage workstations and production lines. The three-dimensional storage workstations are connected to the production lines through transportation mechanisms. The production lines include main production lines and auxiliary production lines. AGV cars and ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com