Method for testing grouting seepage and solidifying characteristics of rock body under yielding bolting-grouting coupling support

A technology of coupling support and characteristic test, applied in the field of rock mechanics, can solve the problems of lack of test methods and lag, and achieve the effect of strong operability, significant basic significance and reasonable theoretical basis

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

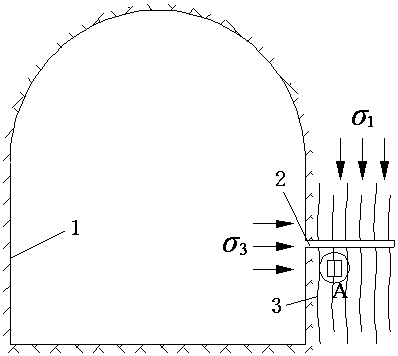

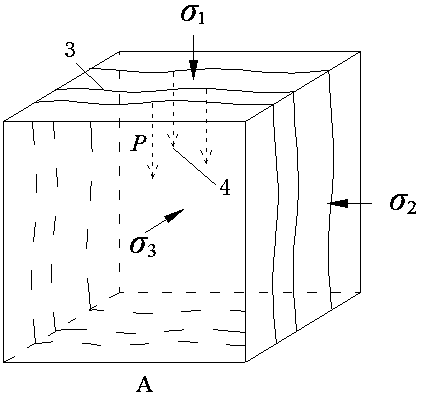

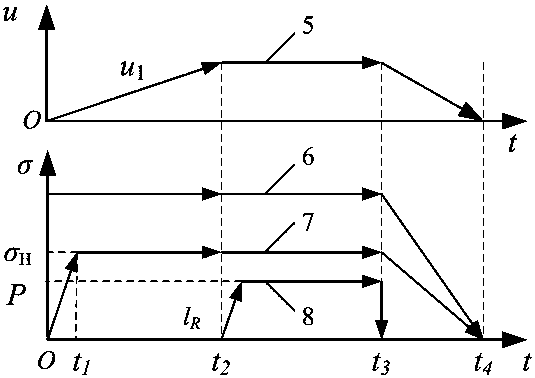

[0021] A test method for rock mass grouting seepage and reinforcement characteristics under pressure anchor injection coupling support: Step 1) Prepare a true triaxial testing machine, including a cube container surrounded by six pressure plates 12, and between each pressure plate 12 Sealing pad 16 is set; Wherein, pressure head is all provided with pressure plate 12 exterior of top, left side and front side, wherein the pressure head that is positioned on top pressure plate 12 is σ 1 Directional pressure head 9, the pressure head located outside the left pressure plate 12 is σ 2 Directional pressure head 10, the pressure head located outside the front side pressure plate 12 is σ 3 The direction pressure head is not shown in the figure; the bottom, right and rear side pressure plates 12 are provided with reaction walls 13 on the outside, and the inside of the top and bottom pressure plates 12 are respectively provided with water-permeable plates, and the top pressure plate 12 ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com