Detection method of dust removal ability of primary flue gas dust removal system of converter

The technology of a dust removal system and detection method is applied in the direction of measuring devices, manufacturing converters, and improvement of process efficiency. It can solve problems such as inability to quantify, flue gas is not within the detection range, and the dust content of flue gas is not accurate. The effect of reducing the concentration of harmful gases and ensuring safety

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0021] The tools that need to be used during the implementation of the detection method of the dedusting ability of the primary flue gas dedusting system of the converter in this embodiment include: communication tools, monitoring guns, cloth strips and smoke detection alarms; at least one operator and a tester are required; Cloth strips are used as a blockage to block the test port, communication tools are used for communication between the operator and the tester, and the smoke detection alarm is worn by the tester.

[0022] The length of the converter flue in this embodiment (the distance between the test port and the converter) is 500 meters, and the flue gas flow velocity is 15-25 meters per second.

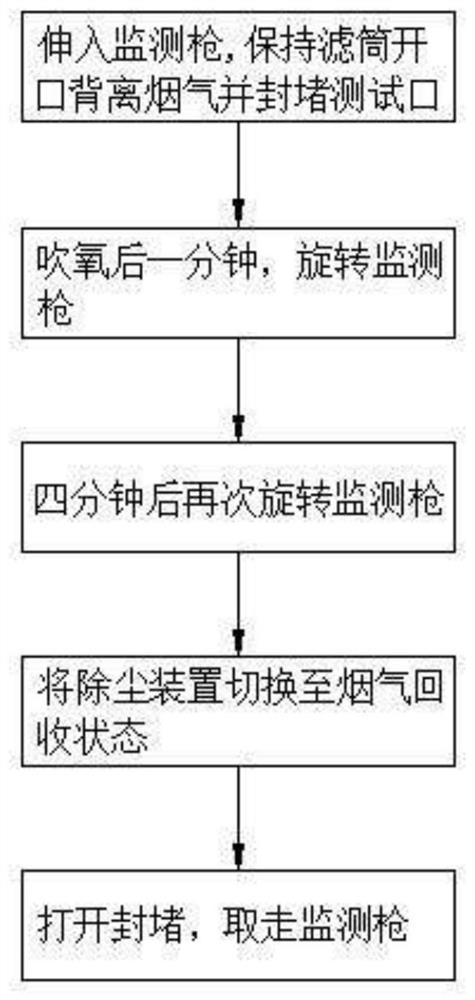

[0023] Such as figure 1 As shown, the detection method steps of the present embodiment are as follows:

[0024] Step 1: After the last round of tapping is completed, the operator notifies the tester; the tester opens the test port of the dust removal device on site, extends...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com